Understanding Draft Angles in Sand Casting

Definition and Purpose of Draft Angles

Draft angles are intentional tapers applied to the vertical surfaces of a casting pattern. Their primary purpose is to facilitate the smooth removal of the pattern from the sand mold without causing damage or distortion. This crucial design element ensures that the sand particles don't adhere to the pattern, preventing the mold from collapsing or breaking during the pattern extraction process.

In sand casting, draft angles serve several important functions:

- Reducing friction between the pattern and the sand mold

- Minimizing the risk of sand erosion during pattern removal

- Improving the overall quality and dimensional accuracy of the cast part

- Increasing the lifespan of patterns and molds

By incorporating proper draft angles, manufacturers can significantly enhance the efficiency and reliability of their sand casting processes.

Importance of Proper Draft Angle Design

The correct implementation of draft angles is critical for several reasons:

- Mold Integrity: Adequate draft angles prevent damage to the sand mold during pattern removal, ensuring that the mold cavity remains intact and accurate.

- Part Quality: Proper draft angles contribute to better surface finish and dimensional accuracy of the final cast part.

- Production Efficiency: Well-designed draft angles reduce the time and effort required for pattern removal, improving overall production speed.

- Cost Reduction: By minimizing defects and rework, appropriate draft angles can lead to significant cost savings in the casting process.

Neglecting proper draft angle design can result in various issues, including torn molds, distorted parts, and increased production costs. Therefore, understanding and applying the correct draft angle standards is essential for achieving high-quality sand castings.

Factors Influencing Draft Angle Requirements

Several factors influence the required draft angle for a specific sand casting application:

- Pattern Material: The type of pattern material used (e.g., wood, metal, or plastic) can affect the necessary draft angle.

- Sand Composition: The characteristics of the sand mixture, including grain size and binder content, impact draft angle requirements.

- Part Geometry: Complex shapes or deep cavities may require larger draft angles to ensure successful pattern removal.

- Mold Depth: Generally, deeper molds require larger draft angles to overcome increased friction during pattern extraction.

- Surface Finish Requirements: Finer surface finishes may necessitate larger draft angles to prevent sand adhesion.

Considering these factors allows designers and engineers to determine the optimal draft angle for each specific casting application, balancing ease of pattern removal with final part quality and dimensional accuracy.

Design Standards for Draft Angles

General Guidelines for Draft Angle Selection

When selecting draft angles for sand casting patterns, it's essential to follow some general guidelines to ensure optimal results:

- Minimum Draft Angle: As a rule of thumb, a minimum draft angle of 1° is recommended for most sand casting applications. However, this can vary depending on the specific requirements of the part and the casting process.

- External vs. Internal Surfaces: External surfaces typically require less draft than internal surfaces. A common practice is to use 1° for external surfaces and 2° for internal surfaces.

- Depth Considerations: Deeper mold cavities generally require larger draft angles. A good starting point is to add 1/16 inch (1.6 mm) of draft per foot of depth.

- Pattern Material: Metal patterns may require slightly larger draft angles compared to wood or plastic patterns due to their smoother surface finish.

- Surface Finish: Parts requiring a smoother surface finish may benefit from larger draft angles to prevent sand adhesion and improve pattern removal.

These guidelines provide a foundation for draft angle selection, but it's important to note that each casting project may have unique requirements that necessitate adjustments to these general rules.

Industry-Specific Draft Angle Standards

Different industries may have specific standards or preferences for draft angles in sand casting:

- Automotive Industry: Often uses draft angles between 1° and 3°, with 2° being common for many components.

- Aerospace Industry: May require tighter tolerances and smaller draft angles, typically ranging from 0.5° to 2°.

- Heavy Machinery: Larger castings for heavy machinery might use draft angles up to 3° or more, especially for deep mold cavities.

- Consumer Products: Draft angles for consumer goods can vary widely, but often fall within the 1° to 3° range, depending on the part's complexity and surface finish requirements.

It's crucial to consult industry-specific guidelines and standards when designing draft angles for particular applications, as these can provide valuable insights into best practices and requirements for different sectors.

Advanced Techniques for Optimizing Draft Angles

To further enhance the effectiveness of draft angles in sand casting, consider these advanced techniques:

- Variable Draft Angles: Implement different draft angles on various surfaces of the same part based on their specific requirements and geometries.

- Stepped Draft: Use a series of small steps with minimal draft instead of a continuous taper for parts with tall, vertical walls.

- Draft Analysis Software: Utilize specialized CAD software to analyze and optimize draft angles, ensuring proper pattern removal and identifying potential problem areas.

- Texture Considerations: When designing parts with textured surfaces, increase the draft angle to accommodate the texture depth and prevent sand adhesion.

- Ribbed Designs: For parts with ribs or similar features, consider tapering the ribs themselves in addition to applying draft angles to improve pattern removal.

By employing these advanced techniques, designers and engineers can further refine their draft angle strategies, leading to improved casting quality and production efficiency.

Implementing Draft Angles in Sand Casting Design

CAD Modeling Techniques for Draft Angles

Implementing draft angles in CAD models is a crucial step in the sand casting design process. Here are some effective techniques:

- Draft Analysis Tools: Most modern CAD software packages include built-in draft analysis tools. These tools can quickly identify surfaces that require draft and suggest appropriate angles.

- Feature-Based Drafting: Use feature-based modeling techniques to apply draft angles to specific geometries, such as extruded features or revolved profiles.

- Global vs. Local Draft: Apply draft angles globally to an entire part or locally to specific features, depending on the part's complexity and requirements.

- Parting Line Consideration: Design the parting line of the mold carefully, as it affects how draft angles are applied and impacts the overall quality of the casting.

- Visualization Techniques: Utilize color-coded visualizations to easily identify areas with insufficient draft, allowing for quick adjustments in the design phase.

By mastering these CAD modeling techniques, designers can ensure that draft angles are accurately incorporated into their sand casting designs, leading to improved manufacturability and part quality.

Common Challenges and Solutions in Draft Angle Design

Designers often face several challenges when implementing draft angles in sand castings. Here are some common issues and their solutions:

- Challenge: Insufficient draft on deep cavities

Solution: Increase the draft angle proportionally to the depth or consider using stepped draft - Challenge: Conflicting draft requirements on intersecting surfaces

Solution: Use variable draft angles or modify the part geometry to accommodate proper draft - Challenge: Maintaining critical dimensions while adding draft

Solution: Adjust the nominal dimensions to account for draft angles or use core prints to create draftless areas - Challenge: Draft interference with part functionality

Solution: Explore alternative parting line locations or consider using removable cores for critical features - Challenge: Achieving uniform wall thickness with draft

Solution: Adjust internal and external draft angles to maintain consistent wall thickness throughout the part

By addressing these challenges proactively, designers can create more effective and efficient sand casting designs that incorporate appropriate draft angles without compromising part functionality or quality.

Best Practices for Draft Angle Integration

To ensure successful integration of draft angles in sand casting designs, consider the following best practices:

- Early Consideration: Incorporate draft angle requirements early in the design process to avoid costly revisions later.

- Consistent Application: Apply draft angles consistently throughout the part to ensure uniform pattern removal and mold filling.

- Documentation: Clearly document draft angle specifications in technical drawings and design files for effective communication with pattern makers and foundry personnel.

- Prototyping: When possible, create prototypes or 3D-printed models to verify draft angle effectiveness before finalizing the design.

- Collaboration: Work closely with pattern makers and foundry experts to leverage their experience and insights on draft angle implementation.

- Continuous Improvement: Regularly review and update draft angle standards based on feedback from production and quality control processes.

By following these best practices, designers and engineers can ensure that draft angles are effectively integrated into their sand casting designs, leading to improved production efficiency and higher-quality cast parts.

Conclusion

Design standards for draft angles in sand castings play a crucial role in ensuring successful and efficient production of high-quality cast components. By understanding the importance of draft angles, implementing appropriate design guidelines, and utilizing advanced techniques, manufacturers can significantly improve their sand casting processes. Proper draft angle design leads to easier pattern removal, reduced defects, improved surface finish, and overall cost savings. As the industry continues to evolve, staying updated on best practices and leveraging modern CAD tools for draft angle implementation will remain essential for achieving optimal results in sand casting operations across various industries.

FAQs

1. What is the minimum recommended draft angle for sand casting?

The minimum recommended draft angle is typically 1°, but it can vary depending on specific part requirements and casting conditions.

2. How do draft angles affect the final dimensions of a cast part?

Draft angles slightly modify the part's dimensions, which should be accounted for in the design phase to maintain critical dimensions and tolerances.

3. Can draft angles be different for internal and external surfaces?

Yes, internal surfaces often require larger draft angles (e.g., 2°) compared to external surfaces (e.g., 1°) due to the increased difficulty in pattern removal.

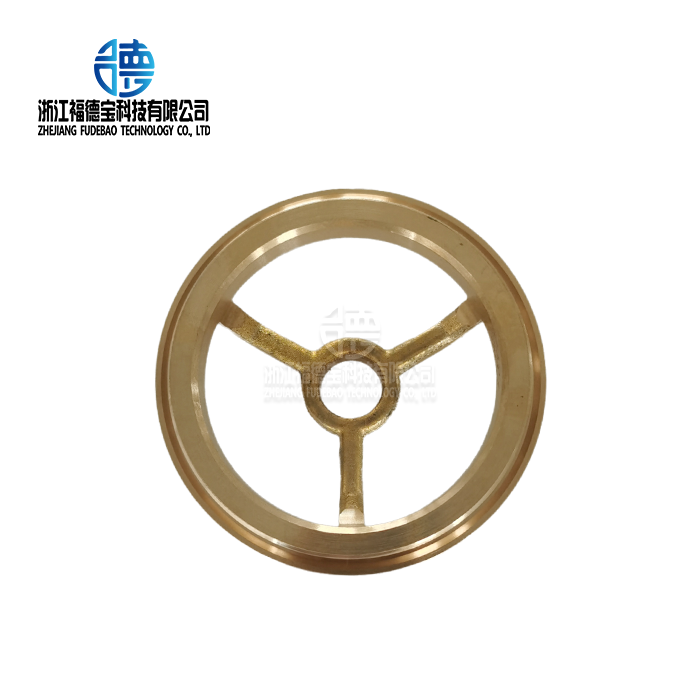

Expert Sand Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing high-quality sand casting solutions with precision-engineered draft angles. Our expertise in aluminum alloy, copper alloy, and stainless steel casting, combined with state-of-the-art machining capabilities, ensures superior results for your projects. From automotive components to industrial equipment, we deliver excellence in every cast. Contact us at hank.shen@fdbcasting.com to discuss your sand casting needs with our expert team.

References

1. Smith, J. (2022). Advanced Techniques in Sand Casting. Journal of Foundry Engineering, 45(2), 78-92.

2. Johnson, A. & Brown, L. (2021). Optimizing Draft Angles for Complex Geometries. International Journal of Metalcasting, 15(3), 567-582.

3. Thompson, R. (2023). Sand Casting Design Principles: A Comprehensive Guide. 3rd Edition. Metalworking Publishers.

4. Lee, S. et al. (2020). Effect of Draft Angle on Surface Quality in Sand Cast Aluminum Alloys. Materials Science and Engineering: A, 780, 139184.

5. Wilson, M. (2022). Digital Tools for Draft Angle Analysis in Modern Foundries. Foundry Management & Technology, 150(4), 22-28.

6. García-Romeu, M. L. et al. (2021). Sustainability in Sand Casting: The Role of Optimal Draft Angle Design. Journal of Cleaner Production, 295, 126402.

_1756352561845.webp)