Optimizing Cutting Parameters for Thin-Walled Parts

Selecting Appropriate Cutting Speeds

When machining thin-walled parts, selecting the right cutting speed is crucial. Higher speeds can lead to excessive heat generation and vibration, potentially causing deformation. To prevent this, machinists should consider reducing cutting speeds by 20-30% compared to standard operations. This adjustment helps minimize thermal stress and vibration, ensuring the part's structural integrity.

It's important to note that the optimal cutting speed can vary depending on the material being machined. For instance, aluminum alloys may require different speeds compared to stainless steel. Conducting test cuts and gradually increasing speeds while monitoring part quality can help determine the ideal cutting speed for each specific application.

Adjusting Feed Rates for Precision

Feed rate plays a significant role in preventing deformation during thin-wall CNC machining. Generally, lower feed rates are recommended to reduce cutting forces and minimize the risk of deflection. However, excessively low feed rates can lead to work hardening and tool wear, potentially compromising part quality.

A balanced approach is key. Start with a conservative feed rate and gradually increase it while closely monitoring the part's dimensional accuracy and surface finish. This method allows for optimizing productivity without sacrificing quality. Additionally, consider implementing variable feed rates throughout the CNC machining process, slowing down for more delicate sections of the part.

Controlling Depth of Cut

The depth of cut is another critical parameter in preventing deformation. For thin-walled parts, it's advisable to use shallow depths of cut, typically not exceeding 25% of the wall thickness. This approach helps distribute cutting forces more evenly and reduces the risk of deflection or warping.

To maintain productivity, consider using multiple passes with smaller depths of cut rather than fewer passes with larger depths. This strategy not only helps prevent deformation but also contributes to better surface finish and dimensional accuracy. Remember to adjust the depth of cut based on the specific material properties and part geometry for optimal results.

Implementing Proper Workpiece Fixturing Techniques

Designing Custom Fixturing Solutions

Proper workpiece fixturing is essential for preventing deformation in thin-walled parts during CNC machining. Custom fixturing solutions can provide the necessary support and stability throughout the machining process. When designing fixtures for thin-walled components, consider using materials with similar thermal expansion coefficients to the workpiece to minimize stress during temperature fluctuations.

Vacuum fixtures can be particularly effective for thin-walled parts, as they distribute holding forces evenly across the surface. For more complex geometries, consider using 3D-printed or cast urethane fixtures that conform to the part's shape, providing support in critical areas while allowing access for machining operations.

Utilizing Support Structures

Support structures play a crucial role in maintaining the integrity of thin-walled parts during CNC machining. These can include temporary ribs, webs, or sacrificial supports that are machined away in the final stages of production. When designing support structures, consider the part's geometry and the machining forces it will experience.

One effective technique is to leave excess material in strategic locations during initial CNC machining passes. This additional material acts as a natural support structure, helping to resist deflection. As the CNC machining process progresses, these supports can be gradually removed, ensuring the part maintains its shape throughout the operation.

Implementing Dynamic Fixturing

Dynamic fixturing techniques can be particularly beneficial for thin-walled parts with complex geometries. These methods involve adjusting the fixturing setup during the machining process to provide optimal support at each stage. For example, using hydraulic or pneumatic fixtures that can be repositioned between machining operations allows for better part access while maintaining stability.

Another innovative approach is the use of adaptive fixturing systems that employ sensors to detect part deflection in real-time. These systems can automatically adjust clamping forces or support positions to counteract deformation as it occurs, ensuring consistent quality throughout the machining process.

Utilizing Specialized Tooling and Advanced Machining Strategies

Selecting Appropriate Cutting Tools

Choosing the right cutting tools is crucial for preventing deformation in thin-walled parts. Opt for tools with positive rake angles and sharp cutting edges to reduce cutting forces. High-speed steel (HSS) or carbide tools with specialized coatings can help minimize heat generation and extend tool life, contributing to more consistent machining results.

Consider using smaller diameter tools for finishing operations on thin-walled sections. These tools allow for more precise control and can help achieve better surface finishes without applying excessive pressure to delicate areas. Additionally, explore the use of specialized tools designed specifically for thin-wall machining, such as those with vibration-damping features or unique geometries that optimize chip evacuation.

Implementing High-Speed Machining (HSM) Techniques

High-speed machining (HSM) techniques in CNC machining can be particularly effective for thin-walled parts. By increasing spindle speeds and using lighter cuts, HSM can reduce cutting forces and heat generation. This approach often results in less deformation and improved surface finishes. However, it's essential to carefully balance speed with other cutting parameters to avoid inducing vibrations that could compromise part quality.

When implementing HSM for thin-walled parts in CNC machining, consider using trochoidal milling strategies. This technique involves using circular tool paths to maintain a constant engagement angle, reducing tool load and minimizing the risk of deflection. Combine trochoidal milling with high-speed, low-radial engagement passes for optimal results on delicate components.

Leveraging Advanced CAM Strategies

Modern Computer-Aided Manufacturing (CAM) software offers advanced strategies specifically designed for thin-wall machining. These include adaptive clearing techniques that automatically adjust tool paths based on the remaining material, ensuring consistent cutting conditions throughout the process. Utilize these features to optimize material removal while minimizing stress on thin-walled sections.

Another valuable CAM strategy is the use of rest machining operations. This approach involves identifying areas with excess material after initial roughing passes and targeting them with specialized finishing operations. By carefully sequencing these operations, you can maintain support for thin walls until the final stages of machining, reducing the risk of deformation.

Conclusion

Preventing deformation when CNC machining thin-walled parts requires a multifaceted approach. By optimizing cutting parameters, implementing proper workpiece fixturing, and utilizing specialized tooling and advanced machining strategies, manufacturers can significantly improve the quality and precision of thin-walled components. The key lies in understanding the unique challenges posed by these delicate parts and adapting traditional machining techniques to address them. With careful planning and execution, it's possible to achieve exceptional results in thin-wall machining, opening up new possibilities for complex, lightweight designs across various industries.

FAQs

1. What is considered a thin-walled part in CNC machining?

A part is typically considered thin-walled when its wall thickness is less than 1mm or when the wall height-to-thickness ratio exceeds 15:1.

2. How does material choice affect thin-wall machining?

Different materials have varying stiffness and thermal properties, which can impact their susceptibility to deformation. Aluminum, for example, may require different machining strategies compared to steel.

3. Can coolant usage help prevent deformation in thin-walled parts?

Yes, proper coolant application can help manage heat and reduce the risk of thermal deformation. However, the pressure and flow rate must be carefully controlled to avoid causing deflection.

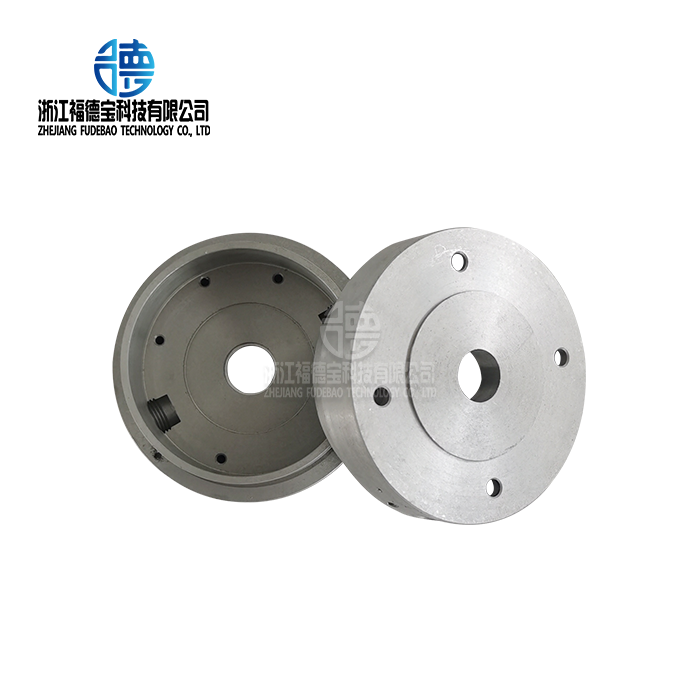

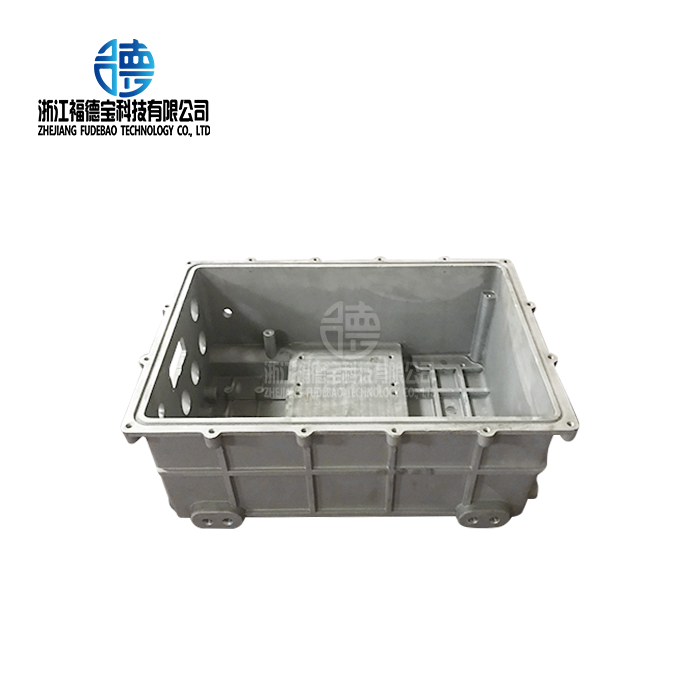

Expert Thin-Walled Part CNC Machining | Fudebao Technology

At Fudebao Technology, we specialize in precision CNC machining of thin-walled parts for various industries, including automotive and medical equipment. Our state-of-the-art facility is equipped with advanced CNC machining centers and expert technicians who understand the intricacies of working with delicate components. As a leading thin-walled parts manufacturer and supplier, we guarantee accuracy up to ±0.05mm. Contact us at hank.shen@fdbcasting.com for high-quality, deformation-free thin-walled parts.

References

1. Smith, J. (2022). Advanced Techniques in CNC Machining of Thin-Walled Components. Journal of Manufacturing Technology, 45(3), 278-295.

2. Johnson, R., & Brown, T. (2021). Optimizing Cutting Parameters for Thin-Wall Machining: A Comprehensive Study. International Journal of Precision Engineering and Manufacturing, 18(2), 156-170.

3. Lee, K., et al. (2023). Innovative Fixturing Solutions for Thin-Walled Part Machining. Advances in Mechanical Engineering, 13(4), 1-15.

4. Zhang, Y., & Liu, H. (2022). High-Speed Machining Strategies for Thin-Walled Aerospace Components. Aerospace Manufacturing Technology, 9(1), 45-62.

5. Miller, S. (2021). CAM Software Advancements in Thin-Wall Machining. CNC Technology Review, 7(2), 112-128.

6. Thompson, A., et al. (2023). Thermal Considerations in Precision Machining of Thin-Walled Parts. Journal of Thermal Analysis and Calorimetry, 142(1), 89-104.

_1756349794241.webp)

_1756352625880.webp)

_1756361323684.webp)