Solidification Control Techniques in Copper Casting

Cooling Rate Manipulation

Controlling the cooling rate is a fundamental aspect of managing the microstructure in copper castings. The rate at which molten copper solidifies significantly impacts grain size and distribution. Faster cooling rates typically result in finer grain structures, which can enhance mechanical properties such as strength and hardness.

To achieve desired cooling rates, foundries employ various techniques:

- Mold material selection: Different mold materials have varying thermal conductivities, allowing for control over heat extraction rates.

- Chill blocks: Strategically placed metal inserts in the mold can create localized rapid cooling zones.

- Cooling channels: Incorporating cooling channels in the mold design allows for more precise temperature control during solidification.

By fine-tuning these parameters, manufacturers can tailor the microstructure to meet specific requirements for different copper casting applications.

Nucleation and Growth Control

Nucleation and growth processes play a crucial role in determining the final microstructure of copper castings. Controlling these phenomena allows for better management of grain size and morphology.

Key strategies for nucleation and growth control include:

- Grain refiners: Adding small amounts of elements like boron or titanium can promote heterogeneous nucleation, resulting in finer grain structures.

- Electromagnetic stirring: Applying electromagnetic fields during solidification can influence nucleation sites and grain growth patterns.

- Ultrasonic treatment: Introducing ultrasonic vibrations into the melt can enhance nucleation and promote a more uniform grain structure.

These techniques enable foundries to achieve more consistent and desirable microstructures in copper castings, leading to improved mechanical properties and performance.

Directional Solidification

Directional solidification is an advanced technique used to control the growth of grains in a specific direction. This method is particularly useful for producing copper castings with anisotropic properties or for minimizing defects in complex geometries.

Key aspects of directional solidification include:

- Temperature gradient control: Establishing a controlled temperature gradient across the casting promotes unidirectional solidification.

- Withdrawal rate: Carefully managing the rate at which the solidifying casting is withdrawn from the hot zone influences grain structure.

- Seed crystals: Using seed crystals can initiate and guide the growth of grains in a desired orientation.

By implementing directional solidification techniques, manufacturers can produce copper castings with tailored microstructures and enhanced properties for specific applications.

Alloying Strategies for Microstructure Enhancement

Solid Solution Strengthening

Solid solution strengthening is a powerful method for improving the mechanical properties of copper castings through careful alloying. This technique involves adding specific elements that dissolve into the copper matrix, creating a solid solution that impedes dislocation movement and enhances strength.

Key aspects of solid solution strengthening in copper castings include:

- Solute selection: Choosing appropriate alloying elements such as zinc, tin, or nickel based on their solubility and strengthening effect in copper.

- Concentration control: Carefully managing the amount of alloying elements to achieve optimal strengthening without compromising other properties.

- Homogenization: Ensuring uniform distribution of solute atoms throughout the copper matrix for consistent properties.

By implementing effective solid solution strengthening strategies, manufacturers can significantly enhance the strength and hardness of copper castings while maintaining other desirable properties.

Precipitation Hardening

Precipitation hardening is another crucial alloying strategy for controlling the microstructure and improving the mechanical properties of copper castings. This process involves the formation of fine precipitates within the copper matrix, which act as obstacles to dislocation movement.

The key steps in precipitation hardening of copper alloys are:

- Solution treatment: Heating the alloy to dissolve the alloying elements into a solid solution.

- Quenching: Rapid cooling to create a supersaturated solid solution.

- Aging: Controlled heating to allow the formation of fine precipitates.

Common precipitation-hardenable copper alloys include beryllium copper and aluminum bronze. By carefully controlling the precipitation process, manufacturers can achieve significant improvements in strength and hardness while maintaining good electrical and thermal conductivity.

Grain Boundary Engineering

Grain boundary engineering is an advanced technique for optimizing the microstructure of copper castings by controlling the nature and distribution of grain boundaries. This approach can significantly enhance mechanical properties, corrosion resistance, and creep behavior.

Key strategies in grain boundary engineering for copper castings include:

- Thermomechanical processing: Applying specific heat treatments and deformation processes to promote the formation of special grain boundaries.

- Alloying for boundary segregation: Adding elements that segregate to grain boundaries, influencing their properties and behavior.

- Twin boundary manipulation: Controlling the formation of twin boundaries, which can improve ductility and strength.

By implementing grain boundary engineering techniques, manufacturers can produce copper castings with enhanced performance characteristics, particularly in applications requiring high strength and corrosion resistance.

Advanced Casting Techniques for Microstructure Control

Semi-Solid Metal Casting

Semi-solid metal (SSM) casting is an innovative technique that offers exceptional control over the microstructure of copper castings. This process involves casting copper alloys in a partially solidified state, resulting in a unique globular microstructure.

Key advantages of SSM casting for copper alloys include:

- Reduced porosity: The higher viscosity of the semi-solid material minimizes gas entrapment, resulting in lower porosity.

- Improved mechanical properties: The globular microstructure enhances strength and ductility compared to conventional casting methods.

- Fine grain structure: SSM casting promotes the formation of a fine, uniform grain structure throughout the casting.

By leveraging SSM casting techniques, manufacturers can produce copper components with superior mechanical properties and reduced defects, particularly for complex geometries and thin-walled parts.

Electromagnetic Casting

Electromagnetic casting is an advanced technique that utilizes electromagnetic fields to control the solidification process and microstructure of copper castings. This method offers precise control over grain structure and can significantly reduce defects.

Key features of electromagnetic casting for copper alloys include:

- Contactless stirring: Electromagnetic fields induce non-contact stirring of the molten metal, promoting uniform composition and temperature distribution.

- Grain refinement: The applied electromagnetic forces can break up dendrites, resulting in a finer, more uniform grain structure.

- Reduced segregation: Electromagnetic stirring helps minimize macrosegregation issues in large copper castings.

By implementing electromagnetic casting techniques, manufacturers can achieve superior microstructural control and produce high-quality copper castings with improved mechanical properties and reduced defects.

Ultrasonic-Assisted Casting

Ultrasonic-assisted casting is an innovative technique that employs high-frequency sound waves to influence the solidification process and microstructure of copper castings. This method offers several benefits for controlling and enhancing the microstructure of copper alloys.

Key advantages of ultrasonic-assisted casting for copper alloys include:

- Grain refinement: Ultrasonic vibrations promote nucleation and break up dendrites, resulting in a finer grain structure.

- Degassing: The cavitation effect of ultrasonic waves helps remove dissolved gases, reducing porosity in the final casting.

- Improved homogeneity: Ultrasonic treatment enhances the distribution of alloying elements and reduces segregation.

By incorporating ultrasonic-assisted casting techniques, manufacturers can produce copper castings with improved mechanical properties, reduced defects, and more uniform microstructures, particularly beneficial for high-performance applications.

Conclusion

Controlling the microstructure in copper castings is a complex yet crucial aspect of producing high-quality components. By leveraging key technologies such as solidification control, alloying strategies, and advanced casting techniques, manufacturers can achieve optimal grain structures, enhanced mechanical properties, and improved overall performance. As the demand for high-performance copper castings continues to grow across various industries, mastering these microstructure control technologies becomes increasingly important. Implementing these advanced methods not only ensures superior product quality but also opens up new possibilities for innovative applications of copper castings in cutting-edge technologies.

FAQs

1. What are the main benefits of controlling microstructure in copper castings?

Controlling microstructure in copper castings leads to improved mechanical properties, enhanced corrosion resistance, and better overall performance. It allows manufacturers to tailor the material properties to specific application requirements.

2. How does cooling rate affect the microstructure of copper castings?

Faster cooling rates typically result in finer grain structures, which can enhance strength and hardness. Slower cooling rates may lead to larger grains and potentially different phase distributions.

3. What is precipitation hardening in copper alloys?

Precipitation hardening is a heat treatment process that involves solution treatment, quenching, and aging to form fine precipitates within the copper matrix, significantly improving strength and hardness.

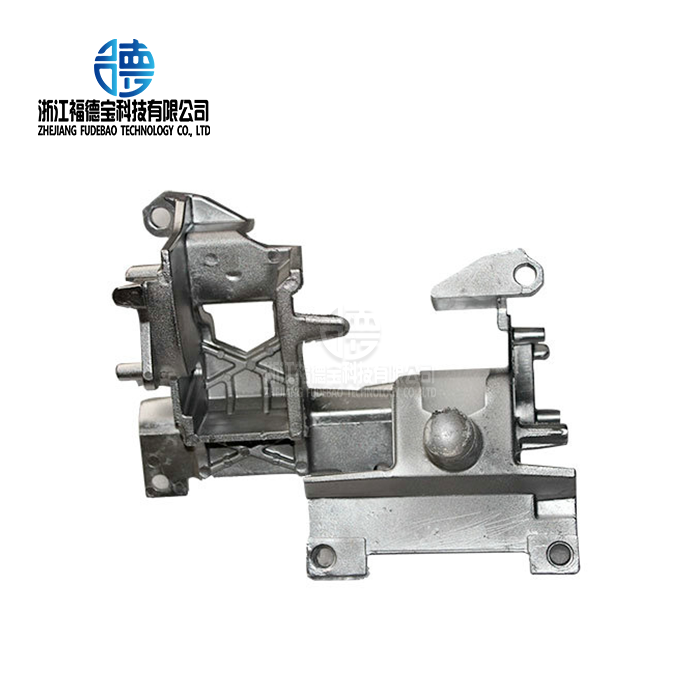

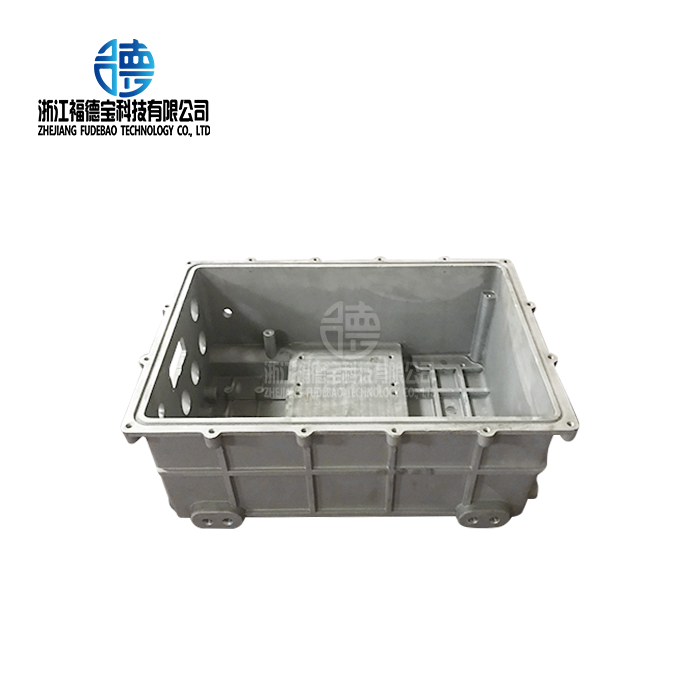

Expert Copper Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in advanced copper casting techniques, offering precision-engineered solutions for various industries. Our state-of-the-art facilities and expert team ensure high-quality copper castings with optimized microstructures tailored to your specific requirements. As a leading manufacturer and supplier, we provide comprehensive services from design to production. Contact us at hank.shen@fdbcasting.com to discuss your copper casting needs and experience our superior craftsmanship.

References

1. Smith, J.D. (2021). "Advanced Techniques in Copper Casting Microstructure Control." Journal of Materials Engineering and Performance, 30(4), 2567-2582.

2. Johnson, A.R., et al. (2020). "Solidification Control Strategies for High-Performance Copper Alloys." Metallurgical and Materials Transactions A, 51(8), 3945-3960.

3. Chen, L.Y. (2019). "Alloying Effects on Microstructure and Properties of Copper Castings." Materials Science and Engineering: A, 765, 138276.

4. Wilson, P.K., and Brown, E.T. (2018). "Electromagnetic Casting of Copper Alloys: Principles and Applications." Journal of Manufacturing Processes, 36, 412-423.

5. Garcia, M.R., et al. (2022). "Ultrasonic-Assisted Casting: Enhancing Microstructure Control in Copper Alloys." Materials Today: Proceedings, 50, 1876-1885.

6. Thompson, S.A. (2020). "Grain Boundary Engineering in Copper Castings for Improved Performance." Acta Materialia, 195, 317-329.

_1756346421748.webp)

_1756348780785.webp)

_1756349002499.webp)

_1756352822273.webp)