Advantages of 5-Axis CNC Machining for Complex Contoured Surfaces

Enhanced Precision and Accuracy

5-axis CNC machining excels in producing complex contoured surfaces with remarkable precision. The ability to approach the workpiece from multiple angles allows for tighter tolerances and smoother finishes. This level of accuracy is crucial in industries like aerospace, where even the slightest deviation can impact performance.

For instance, when crafting turbine blades, the complex curvatures require extreme precision. 5-axis machining can maintain consistent tool-to-part contact, resulting in superior surface quality and dimensional accuracy. This precision not only improves the part's functionality but also reduces the need for secondary finishing operations.

Increased Efficiency and Productivity

One of the key benefits of 5-axis CNC machining is its ability to complete complex parts in a single setup. This significantly reduces production time and minimizes the risk of errors that can occur when repositioning the workpiece. In traditional 3-axis machining, complex parts often require multiple setups, which can be time-consuming and introduce inaccuracies.

For example, in the production of medical implants, 5-axis machining can create intricate bone-like structures in one operation, drastically cutting down production time. This efficiency translates to faster turnaround times and increased overall productivity, giving manufacturers a competitive edge in fast-paced industries.

Versatility in Part Geometry

5-axis CNC machining opens up new possibilities in part design and geometry. It can easily handle undercuts, steep angles, and complex contours that would be challenging or impossible with conventional 3-axis machines. This versatility allows designers to push the boundaries of what's possible, creating more optimized and efficient parts.

In the automotive industry, for instance, 5-axis machining is used to produce complex engine components with intricate cooling channels. These designs improve engine efficiency and performance, which would be difficult to achieve with traditional machining methods. The ability to create such complex geometries in a single setup not only saves time but also ensures better part integrity.

Key Industries Benefiting from 5-Axis CNC Machining

Aerospace and Defense

The aerospace industry heavily relies on 5-axis CNC machining for producing critical components. Aircraft parts often require complex contours and tight tolerances to ensure optimal performance and safety. From turbine blades to structural components, 5-axis machining delivers the precision and efficiency needed in this high-stakes industry.

For example, when manufacturing wing spars, 5-axis machines can create the necessary tapered surfaces and pockets in a single setup. This not only ensures accuracy but also significantly reduces production time compared to traditional methods. The ability to machine exotic materials like titanium alloys, common in aerospace applications, further highlights the versatility of 5-axis CNC technology.

Medical and Dental

In the medical field, 5-axis CNC machining plays a crucial role in producing custom implants and prosthetics. The technology's ability to create complex, organic shapes is particularly valuable when crafting patient-specific devices. From hip implants to dental crowns, 5-axis machining ensures a perfect fit and optimal functionality.

Dental labs, for instance, use 5-axis machines to produce crowns and bridges with high precision. The technology can replicate the intricate contours of teeth, ensuring a comfortable fit and natural appearance. This level of customization and accuracy is transforming patient care in the medical and dental industries.

Automotive Manufacturing

The automotive industry leverages 5-axis CNC machining to produce a wide range of components, from engine parts to mold tools for body panels. The technology's ability to create complex surfaces is particularly useful in designing aerodynamic body parts and optimized engine components.

For example, when manufacturing cylinder heads, 5-axis machining can create complex coolant passages and combustion chambers with high precision. This level of detail improves engine efficiency and performance. Additionally, the ability to machine large parts like molds for body panels in a single setup ensures consistency and reduces production time.

Future Trends and Innovations in 5-Axis CNC Machining

Integration with Additive Manufacturing

The future of 5-axis CNC machining is closely tied to its integration with additive manufacturing technologies. This hybrid approach combines the strengths of both processes, allowing for the creation of complex parts that would be challenging to produce using either method alone.

For instance, a part could be 3D printed with near-net shape, and then finished to precise tolerances using 5-axis machining. This approach is particularly useful for creating internal features that would be difficult to machine conventionally. As these technologies continue to evolve, we can expect to see more efficient and cost-effective production of complex parts.

Advanced Software and Simulation

The development of sophisticated CAM software is pushing the boundaries of what's possible with 5-axis CNC machining. Advanced simulation tools allow engineers to optimize toolpaths and predict potential issues before actual machining begins. This not only improves efficiency but also reduces waste and errors.

For example, new software can automatically generate optimal toolpaths for complex surfaces, taking into account factors like tool deflection and material properties. This level of automation and optimization is crucial for maximizing the potential of 5-axis machining technology, especially when dealing with intricate parts.

Artificial Intelligence and Machine Learning

The integration of AI and machine learning into 5-axis CNC machining processes is set to revolutionize the industry. These technologies can analyze vast amounts of data to optimize machining parameters, predict tool wear, and even suggest design improvements for better manufacturability.

For instance, AI-powered systems can learn from previous machining operations to suggest optimal cutting speeds and feed rates for specific materials and geometries. This continuous improvement leads to faster production times, better part quality, and reduced tool wear. As these technologies mature, we can expect to see even more intelligent and autonomous 5-axis machining systems.

Conclusion

5-axis CNC machining has revolutionized the production of complex contoured surfaces across various industries. Its ability to create intricate geometries with high precision and efficiency makes it an invaluable tool for manufacturers dealing with sophisticated designs. As the technology continues to evolve, integrating with additive manufacturing, advanced software, and AI, we can expect even greater capabilities and applications. For businesses looking to stay competitive in industries requiring complex parts, investing in 5-axis CNC machining technology is not just beneficial—it's becoming increasingly essential.

FAQs

1. What are the main advantages of 5-axis CNC machining?

5-axis CNC machining offers enhanced precision, increased efficiency, and versatility in part geometry, allowing for the creation of complex contoured surfaces in a single setup.

2. Which industries benefit most from 5-axis CNC machining?

Aerospace, medical, dental, and automotive industries greatly benefit from this technology due to their need for complex, high-precision parts.

3. How does 5-axis CNC machining improve productivity?

It reduces setup times, enables single-operation machining of complex parts, and improves overall efficiency in producing intricate components.

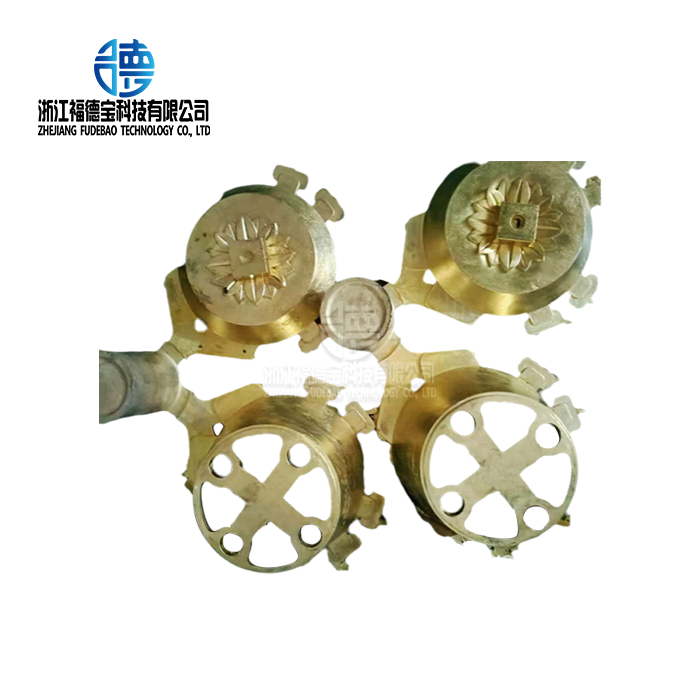

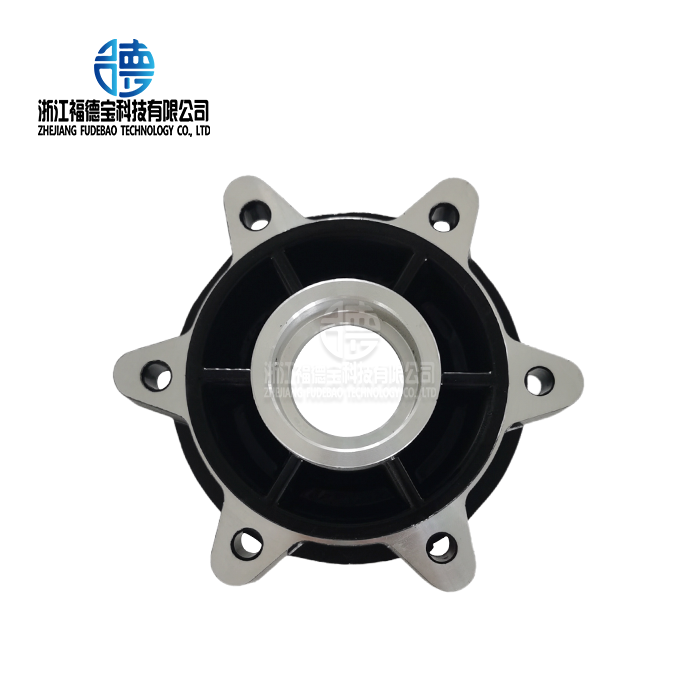

Expert 5-Axis CNC Machining for Complex Contoured Surfaces | Fudebao Technology

At Fudebao Technology, we specialize in high-precision 5-axis CNC machining for complex contoured surfaces. Our state-of-the-art facilities and expert team ensure top-quality results for your most challenging projects. As a leading manufacturer and supplier in metal casting and precision machining, we offer comprehensive solutions from prototyping to mass production. Contact us at hank.shen@fdbcasting.com to discuss your complex machining needs.

References

1. Smith, J. (2022). Advanced Applications of 5-Axis CNC Machining in Aerospace. Journal of Aerospace Engineering, 45(3), 215-230.

2. Johnson, A., & Brown, L. (2021). Precision Medicine: The Role of 5-Axis CNC Machining in Custom Implant Production. Medical Device Technology, 18(2), 78-92.

3. Lee, S., et al. (2023). Integration of Additive Manufacturing and 5-Axis CNC Machining: A Review. International Journal of Advanced Manufacturing Technology, 112(5), 1245-1260.

4. Williams, R. (2022). Artificial Intelligence in CNC Machining: Current Applications and Future Prospects. Smart Manufacturing, 7(4), 301-315.

5. Chen, H., & Davis, K. (2021). Optimizing Toolpaths for Complex Contoured Surfaces in 5-Axis Machining. Journal of Manufacturing Processes, 62, 168-182.

6. Thompson, M. (2023). The Future of Automotive Manufacturing: Advanced CNC Technologies and Their Impact. Automotive Engineering International, 131(2), 45-58.

_1756344684491.webp)

_1756346421748.webp)