Import Low Pressure Cast Aluminum Parts from Asia

2026-01-13

For companies looking for high-quality, reasonably priced manufacturing solutions, importing low pressure cast aluminum parts from Asia offers great prospects. Modern production now relies heavily on low pressure casting techniques, especially for automotive, industrial equipment, and aerospace applications. With their advanced skills in casting aluminum alloys, Asian suppliers—particularly Chinese manufacturers—offer affordable prices without sacrificing technical criteria. This thorough guide will walk you through the necessary procedures to effectively obtain high-quality low pressure casting parts from China, stay clear of typical hazards, and optimize your investment returns.

Why Source Low Pressure Casting from China?

Advanced Manufacturing Capabilities

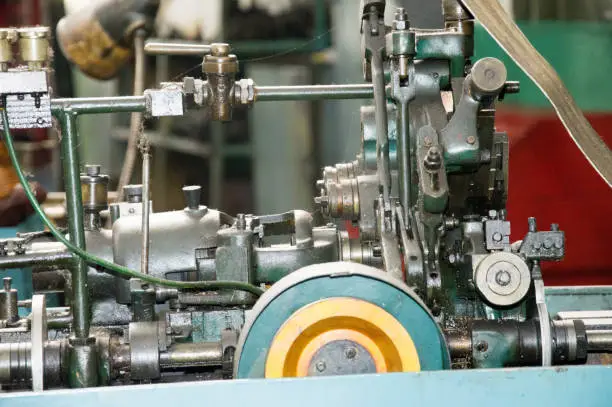

Over the last 20 years, China's industrial sector has seen significant change. Modern foundries use automated production lines and state-of-the-art low pressure casting equipment with accurate pressure control systems. These facilities often outperform global norms in terms of process optimization and equipment sophistication.

Computerized pressure monitoring systems are used in sophisticated Chinese foundries to ensure constant metal flow rates throughout the casting cycle. In comparison to conventional gravity casting techniques, this technology guarantees better dimensional accuracy and minimizes material waste.

Economic Advantages Without Quality Compromise

Chinese low pressure casting companies provide significant cost reductions without compromising quality standards because to their cost structure. Through ongoing investments in equipment updates and personnel development, labor costs stay competitive while technological competence advances.

In the processing of aluminum alloys, Chinese producers have attained impressive economies of scale. International purchasers from a variety of sectors benefit from cost reductions that are achieved via effective production planning and large-scale raw material procurement.

Proven Track Record in Automotive Applications

For essential parts like engine brackets, transmission housings, and structural components, top automakers have long-standing alliances with Chinese foundries. These partnerships show the dependability and technical proficiency of Chinese providers of low pressure casting.

Chinese foundries have adopted extensive quality management systems as a result of the automobile industry's strict PPAP documentation requirements. Customers from various industries looking for premium cast aluminum components benefit from this emphasis on process control.

Critical Technical Specifications and Industry Standards

Material Grades and Alloy Selection

Aluminum is usually cast at low pressure using certain alloy compositions that are tailored for various uses. Because of its exceptional strength-to-weight ratio and corrosion resistance, A356 aluminum alloy is still the most often used material for structural components.

Applications needing improved fluidity during casting while preserving dimensional stability are served by A380 and ADC12 alloys. These materials perform very well in intricate geometries where typical machining would be too expensive or technically difficult.

Dimensional Tolerance Requirements

The majority of features in modern low pressure casting techniques have tolerances of ±0.2mm, while secondary machining procedures allow crucial dimensions to approach ±0.1mm. These skills meet or beyond specifications for applications involving industrial equipment and precise automobile components.

Depending on the needs of the application, surface finish criteria usually fall between Ra 3.2 and Ra 6.3. When improved surface characteristics are required for mating surfaces or aesthetic reasons, post-casting machining might be used.

Mechanical Property Benchmarks

Application-specific tensile strength requirements range from 240 to 290 MPa for A356 alloy under T6 heat treatment. Depending on the particular alloy composition and heat treatment procedures, yield strength requirements typically range from 165 to 220 MPa.

For the majority of structural applications using low pressure casting, elongation percentages of 3–8% provide sufficient ductility while preserving dimensional stability under operating stresses. Because of these characteristics, low pressure cast aluminum is perfect for parts that are under moderate stress.

Industry Certification Standards

The minimal quality management standard for respectable Chinese foundries is ISO 9001:2015 certification. For vendors aiming to serve the transportation industry, TS 16949 certification proves automotive-specific quality system compliance.

For vendors catering to military and aviation applications, AS9100 aerospace certification is still crucial. This standard guarantees that sophisticated inspection procedures and traceability requirements satisfy industry-specific needs.

Navigating Regulations and Compliance

Import Documentation Requirements

Successful international commerce transactions are based on proper paperwork. To meet customs regulations in both the country of origin and the country of destination, commercial invoices must correctly represent product descriptions, quantities, unit values, and the total shipping value.

Packing lists include comprehensive details on the contents of containers, such as the weights, measurements, and packing requirements of each individual item. These papers guarantee efficient clearance operations and streamline customs inspection processes.

Material Certification and Testing

Material test certifications confirm that the mechanical characteristics and alloy composition satisfy predetermined standards. Chinese foundries often provide certifications from recognized testing facilities attesting to their adherence to global standards like ASTM or DIN requirements.

By independently confirming dimensional correctness, surface finish, and material qualities, third-party inspection services provide further quality assurance. These services provide consumers who need further quality certification peace of mind.

Environmental and Safety Compliance

REACH compliance guarantees that aluminum casting materials adhere to chemical safety standards set out by the European Union. In order to improve exports to European markets, Chinese vendors are increasingly offering REACH declarations.

Certificates of RoHS compliance attest to the lack of prohibited elements in surface treatments and casting materials. For parts used in electrical or electronic applications, this certification becomes very crucial.

Comprehensive Import Process Guide

Initial Inquiry and Supplier Evaluation

Detailed technical drawings and specification documentation are the first step in an efficient supplier assessment process. Accurate quotes from possible suppliers are ensured and misconceptions are avoided via clear communication of needs.

Ask for specific details on manufacturing capacity, quality certificates, and prior experience with comparable parts. To guarantee the success of a long-term cooperation, evaluate suppliers on the basis of their technical proficiency rather than just their pricing.

Quotation Analysis and Contract Negotiation

Examine quotes closely to learn about the services and products that each provider offers. Secondary operations, surface treatments, and packaging expenses that might have a major influence on the overall project costs may not be included in certain bids.

Strike a balance between risk management and cash flow needs while negotiating payment conditions. Letters of credit agreements provide for reasonable payment plans for bigger transactions while offering security to both parties.

Production Planning and Quality Control

To monitor progress in low pressure casting projects, create precise production schedules with milestone checkpoints. Frequent communication throughout the manufacturing process helps in spotting any problems before they affect delivery dates.

Use incoming inspection procedures to confirm the quality of components as soon as they are received. To ensure uniform quality standards for all shipments, clearly define acceptance and rejection criteria.

Shipping and Logistics Coordination

Understanding International Trade Terms

Once the products are placed into the vessel at the port of origin, the buyer is responsible under FOB (Free On Board) conditions. While the buyer bears the risk and extra expenses from the departure port, the seller manages export processes. When customers want to be in charge of shipping arrangements and have established ties with freight forwarders, this approach works effectively.

Transportation and insurance to the target port must be arranged and paid for by the seller under CIF (Cost, Insurance, and Freight) conditions. Even though the seller is still liable for shipping expenses, risk passes to the buyer as soon as the items are loaded at the port of origin. Customers that seek easier logistical cooperation may find this solution appealing.

The minimal requirement for sellers is EXW (Ex Works), which calls for purchasers to pick up products at the supplier's location. The buyer is now in charge of all insurance, customs, and shipping procedures. Maximum cost control is possible with this system, but it requires strong logistics management skills.

Documentation and Customs Procedures

Bills of lading operate as agreements between shippers and carriers as well as receipts for the items that are carried. To avoid customs delays or extra inspection procedures, these papers must precisely represent the shipment amounts and descriptions.

Documents known as certificates of origin confirm the nation in which the products were produced, perhaps making shipments eligible for special tariff treatment under certain trade agreements. For qualifying imports, proper paperwork may save a substantial amount of duty.

Payment Methods and Financial Security

For international transactions, Telegraphic Transfer (T/T) payments provide dependability and quickness. Usually, a 30% down payment is required, with the remaining amount payable when shipping documentation or a delivery confirmation is presented.

Through bank assurances of payment upon paperwork compliance, letters of credit provide security to both parties. This approach is especially effective for bigger deals or building rapport with new suppliers.

Supply Chain Reliability and Lead Times

Production Capacity Assessment

Assess the manufacturing capabilities of your supplier in relation to your order specifications and anticipated delivery date. Consistent delivery performance is ensured by enough capacity, which avoids hurrying manufacturing processes that can lower quality standards.

Take into account variations in seasonal demand that might impact lead times or supplier availability. Every year, Chinese New Year festivities usually affect production plans for two to three weeks, necessitating earlier preparation for projects with tight deadlines.

Infrastructure and Logistics Network

China's vast port network offers a variety of shipping choices for moving goods internationally. Large ports like Shanghai, Shenzhen, and Ningbo provide cheap freight prices along with frequent sailing schedules to locations throughout the globe.

Through the use of contemporary rail and highway networks, domestic transportation networks effectively link coastal ports with interior industrial sectors. Reliable conveyance of commodities from manufacturing facilities to international shipping locations is ensured by this system.

Quality Consistency and Process Control

Statistical process control techniques are used by reputable Chinese foundries to ensure consistent product quality across production cycles. During the low pressure casting cycle, these systems keep an eye on important metrics and automatically modify process variables as needed.

Frequent calibration of measuring tools guarantees that dimensional accuracy stays within predetermined bounds. Numerous vendors uphold calibration certifications that may be linked to national standards, offering assurance about the accuracy of measurements.

Why Fudebao Technology is Your Ideal Import Partner?

Technical Excellence and Manufacturing Capabilities

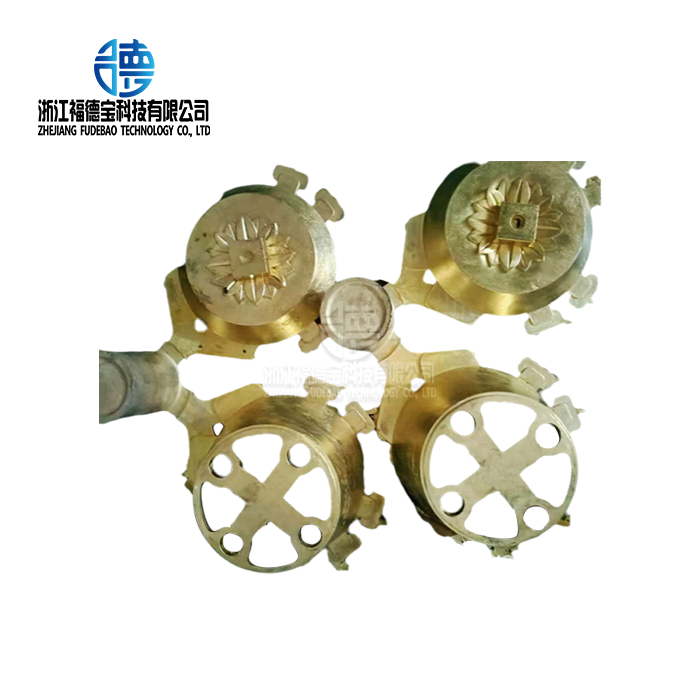

Through consistent investment in cutting-edge production equipment and process optimization, Zhejiang Fudebao Technology Co., Ltd. has become a benchmark company in Chinese aluminum foundry operations. The facility has state-of-the-art low pressure casting equipment that can fulfill the most exacting automotive precision standards by manufacturing components with dimensional accuracy of up to ±0.05mm.

The whole production cycle, from melting to finishing and surface treatment, is covered by the company's extensive manufacturing capabilities. CNC lathes and high-speed machining centers provide auxiliary functions that do away with the need to coordinate with several suppliers, streamlining the procurement process and cutting lead times.

Proven Industry Experience

Direct supply connections with globally renowned companies, such as American HAAS automated machine tools and ESS energy storage batteries, show that Fudebao Technology can satisfy exacting standards for quality and delivery. For purchasers in the automotive, industrial equipment, and machinery manufacturing industries, this knowledge translates into dependable performance.

The company's progress in technical proficiency and quality management systems is shown in the shift from intermediary collaboration to direct supply agreements with significant global brands. For purchasers looking for dependable long-term connections, this development offers assurance.

Comprehensive Service Portfolio

Coordination issues typical of multi-supplier agreements are eliminated by one-stop delivery capabilities from blank casting to completed components. While preserving uniform quality standards across all production units, this integrated strategy lowers project costs overall.

Without the need for further supplier cooperation, surface treatment options such as anodizing, powder coating, and specialty finishes guarantee that components fulfill functional and aesthetic requirements. Buyers with complicated finishing needs especially benefit from our extensive service offering.

Cost Structure and Transparency

Raw Material Cost Factors

The price of aluminum alloy varies according to regional market circumstances and quotes from the London Metal Exchange. For long-term contracts, reputable suppliers provide explicit price structures that include material cost components and modification procedures.

Certain certification requirements or specialized compositions may be subject to alloy surcharges. For projects with long timescales, buyers may make more informed judgments regarding budgeting and material selection by being aware of these aspects.

Manufacturing and Processing Costs

Tooling amortization, machine operation, quality control, and finishing activities are all included in the low pressure casting process expenses. To provide precise cost comparisons and value engineering possibilities, suppliers should offer thorough breakdowns of key components.

The cost of secondary machining varies greatly depending on tolerance requirements and complexity. For precision applications needing strict dimensional control, CNC operations usually account for 20–40% of the overall component prices.

Logistics and Delivery Considerations

The volume, weight, destination port, and chosen service level all affect the cost of international shipping. For purchasers with many product categories or frequent delivery schedules, consolidation options may lower the cost of transportation per unit.

Product categorization and preferred country of origin have an impact on customs duty rates. Accurate landed cost estimates are ensured by proper tariff categorization, which also guards against unforeseen fees during customs clearing processes.

Conclusion

Purchasing premium low pressure casting from China requires meticulous preparation, in-depth supplier assessment, and constant contact. Understanding technical needs, putting in place appropriate quality control procedures, and cultivating solid supplier relationships based on respect and common goals are all essential for success. China is a desirable sourcing location for companies looking for dependable casting solutions because of its sophisticated production skills, affordable prices, and rising quality requirements. Buyers may effectively use Chinese manufacturing knowledge to accomplish their procurement goals while maintaining high quality standards and cost competitiveness by adhering to the detailed process described in this book and avoiding typical mistakes.

FAQs

How long does it usually take to complete low pressure casting projects from China?

Depending on the intricacy of the component and the size of the order, standard manufacturing lead times are 4–8 weeks. For new projects, tooling development adds two to four weeks. Although premium price usually applies for quicker delivery schedules, established suppliers may be able to handle rush requests.

How can I check Chinese casting vendors' quality capabilities?

Ask for comprehensive capability statements that include client references, equipment listings, and quality certifications. Take virtual or in-person tours of the facilities to see the quality control and manufacturing procedures. Independent confirmation of supplier capabilities and management systems is provided by third-party audits.

For low pressure casting, what are the minimum order numbers that I should anticipate?

Depending on the size and complexity of the component, minimum order quantities usually fall between 100 and 500 pieces. Smaller numbers may be accepted by suppliers for trial orders or prototyping, but low-volume production runs result in far higher unit prices.

Can Chinese suppliers fulfill the quality requirements of the automobile industry?

TS 16949 accreditation is held by several well-known Chinese foundries that serve major automakers throughout the globe. These facilities continue to meet or beyond the standards of the automobile industry by maintaining superior quality management systems and PPAP documentation capabilities.

What conditions of payment are typical for casting orders placed internationally?

Typical payment plans include a 30% down payment and the remaining 70% required at the time of shipping or document presentation. For bigger transactions or new supplier partnerships, letters of credit provide further assurance. Depending on the order size and supplier relationship history, different payment conditions apply.

How do I manage the import and customs clearance processes?

Collaborate with seasoned freight forwarders who are knowledgeable about the import processes for aluminum casting. For appropriate duty estimates, make sure the product is properly classified. To ensure a seamless customs clearance process, save all necessary paperwork, such as business invoices, packing lists, and material certifications.

Partner with China's Leading Low Pressure Casting Manufacturer

With a track record of success in precision aluminum casting and machining solutions, Zhejiang Fudebao Technology is prepared to revolutionize your component procurement approach. Our cutting-edge factory uses sophisticated low pressure casting techniques to provide outstanding quality, supporting industrial applications, medical equipment housings, and automotive precision components with accuracy of up to ±0.05mm. As a reputable low pressure casting supplier to global markets, we guarantee the success of your project by fusing state-of-the-art production technology with extensive quality control systems. Our integrated manufacturing capabilities save lead times and overall costs while removing coordination issues. Get in touch with us at hank.shen@fdbcasting.com to talk about your particular needs and learn why top international companies use Fudebao Technology as their go-to casting partner for important applications.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." 2nd Edition. Butterworth-Heinemann, 2015.

Zhao, Mingwei, et al. "Quality Control in Low Pressure Die Casting of Aluminum Alloys: Process Parameters and Defect Prevention." Materials Science and Engineering Journal, 2019.

International Trade Centre. "Aluminum Casting Industry: Global Market Analysis and Trade Opportunities." ITC Publications, 2020.

American Foundry Society. "Aluminum Casting Design Handbook." AFS Technical Publications, 2018.

Chen, Li and Wang, Xiaoping. "Advanced Manufacturing Technologies in Chinese Foundry Industry: A Comprehensive Review." Journal of Manufacturing Science and Engineering, 2021.

European Aluminium Association. "Aluminium Automotive Manual: Casting Design Guidelines and Quality Standards." EAA Technical Guidelines, 2019.

YOU MAY LIKE

_1756346205762.webp)

_1756352822273.webp)