Understanding Aerospace Casting Processes

Investment Casting: Precision and Complexity

Investment casting, also known as lost-wax casting, is a preferred method for creating complex aerospace components with high dimensional accuracy. This process involves creating a wax pattern of the desired part, coating it with ceramic material to form a mold, melting out the wax, and then pouring molten metal into the cavity. Investment casting offers several advantages for aerospace applications:

- Excellent surface finish and dimensional accuracy

- Ability to produce intricate shapes and thin-walled sections

- Suitable for a wide range of alloys, including superalloys used in aircraft engines

- Reduces the need for extensive machining, saving time and costs

However, investment casting can be more expensive for large production runs and may have limitations on the size of components that can be produced.

Sand Casting: Versatility and Large-Scale Production

Sand casting is a versatile and cost-effective casting process for producing larger aerospace components. This process involves creating a mold from compacted sand, pouring molten metal into the mold, and allowing it to solidify. Sand casting offers several benefits for aerospace manufacturing:

- Ability to produce large and heavy components

- Suitable for low to medium production volumes

- Flexibility in design changes and prototyping

- Cost-effective for larger parts compared to other casting methods

While sand casting may not achieve the same level of precision as investment casting, it remains a popular choice for many structural aerospace components.

Die Casting: High-Volume Production

Die casting is a high-speed, high-volume casting process that involves injecting molten metal into a reusable mold under high pressure. This method is particularly suitable for smaller, less complex aerospace components that require high production rates. Benefits of die casting include:

- Excellent dimensional accuracy and surface finish

- High production rates, making it cost-effective for large volumes

- Ability to produce thin-walled components

- Consistent part quality across production runs

However, die casting is limited in the size of components it can produce and may not be suitable for all aerospace alloys due to the high pressures involved.

Factors Influencing Casting Process Selection

Component Geometry and Complexity

The geometry and complexity of the aerospace component play a crucial role in selecting the appropriate casting process. Intricate designs with fine details, thin walls, or complex internal structures often favor investment casting. This process can produce parts with exceptional dimensional accuracy and surface finish, making it ideal for components like turbine blades or impellers.

For larger, less complex parts such as engine casings or structural components, sand casting may be more suitable. It offers greater flexibility in terms of size and can accommodate a wide range of geometries. Die casting, on the other hand, is best suited for smaller components with relatively simple geometries that require high-volume production.

When evaluating component geometry, consider factors such as:

- Overall size and weight of the part

- Presence of undercuts or complex internal features

- Required wall thickness and dimensional tolerances

- Surface finish requirements

Material Selection and Properties

The choice of material for aerospace components is critical and can significantly influence the selection of the casting process. Different casting methods are better suited to certain types of alloys and their specific properties. Consider the following aspects when selecting a casting process based on material properties:

- Melting temperature and fluidity of the alloy

- Mechanical properties required (strength, ductility, fatigue resistance)

- Corrosion resistance and thermal stability

- Compatibility with post-casting treatments (heat treatment, surface finishing)

For example, investment casting is well-suited for high-temperature alloys and superalloys commonly used in aerospace applications. Sand casting can accommodate a wide range of alloys but may have limitations with some high-temperature materials. Die casting is typically used with aluminum alloys and other lower-melting-point metals.

Production Volume and Cost Considerations

Production volume and cost are critical factors in selecting the most appropriate casting process for aerospace components. Each casting method has its own economic sweet spot in terms of production quantity:

- Investment casting: Ideal for low to medium production volumes, especially for complex parts

- Sand casting: Suitable for low to high volumes, particularly for larger components

- Die casting: Most cost-effective for high-volume production of smaller parts

When evaluating costs, consider not only the initial tooling and setup expenses but also the per-unit production costs, finishing requirements, and potential scrap rates. For example, while investment casting may have higher initial costs due to tooling, it can be more economical for complex parts that would otherwise require extensive machining.

Additionally, consider the total lifecycle costs, including:

- Tooling and mold creation costs

- Material costs and wastage

- Labor and production time

- Post-casting processing and finishing costs

- Quality control and inspection expenses

By carefully analyzing these factors, manufacturers can select the most cost-effective casting process that meets the required quality standards for their aerospace components.

Optimizing Casting Processes for Aerospace Applications

Quality Control and Testing Procedures

Maintaining rigorous quality control and testing procedures is paramount in aerospace casting. The high-stakes nature of the industry demands components that meet or exceed stringent safety and performance standards. To ensure the highest quality in cast aerospace parts, manufacturers should implement comprehensive quality control measures, including:

- Non-destructive testing (NDT) methods such as X-ray, ultrasonic, and magnetic particle inspection

- Destructive testing on sample parts to verify mechanical properties

- Dimensional inspection using coordinate measuring machines (CMM) or 3D scanning

- Chemical analysis to ensure material composition meets specifications

- Microstructure examination to verify proper grain structure and absence of defects

Additionally, implementing statistical process control (SPC) can help monitor and improve the consistency of the casting process over time. By tracking key process parameters and part characteristics, manufacturers can identify trends and address potential issues before they lead to non-conforming parts.

Advanced Technologies in Aerospace Casting

- Rapid prototyping and 3D printing for pattern and mold creation

- Computer simulation and modeling for optimizing mold design and casting parameters

- Vacuum-assisted casting for improved material properties and reduced porosity

- Hot isostatic pressing (HIP) for enhancing mechanical properties and eliminating internal defects

- Additive manufacturing for creating complex cores and molds

These advanced technologies not only improve the quality and performance of cast aerospace components but also can reduce lead times and costs associated with traditional casting methods. For instance, 3D printing of patterns for investment casting can significantly reduce tooling costs and time for prototyping or low-volume production runs.

Sustainability and Environmental Considerations

As the aerospace industry increasingly focuses on sustainability, casting processes must also evolve to minimize environmental impact. When selecting and optimizing casting processes for aerospace components, consider the following environmental aspects:

- Energy efficiency of the casting process

- Material utilization and recycling capabilities

- Reduction of waste and emissions

- Use of environmentally friendly materials in mold and core production

- Implementing closed-loop systems for water and sand recycling in sand casting operations

For example, investment casting can often produce near-net-shape parts, reducing the need for extensive machining and minimizing material waste. Sand casting facilities can implement sand reclamation systems to reduce waste and conserve resources. Die casting, while energy-intensive, can be optimized for efficiency through proper thermal management and cycle time reduction.

By considering these environmental factors alongside performance and cost considerations, aerospace manufacturers can select casting processes that not only meet their technical requirements but also align with sustainability goals and regulatory compliance.

Conclusion

Selecting the right casting process for aerospace components is a complex decision that requires careful consideration of multiple factors. By understanding the strengths and limitations of investment casting, sand casting, and die casting, manufacturers can make informed choices that balance quality, cost, and production requirements. Factors such as component geometry, material properties, production volume, and environmental considerations all play crucial roles in the decision-making process. As aerospace technology continues to advance, staying abreast of new casting technologies and optimization techniques will be essential for manufacturers looking to maintain a competitive edge in this demanding industry.

FAQs

1. What is the most common casting process used in aerospace manufacturing?

Investment casting is one of the most common processes due to its ability to produce complex, high-precision components.

2. How does material selection impact the choice of casting process?

Different materials have varying melting points, fluidity, and mechanical properties, which can influence the suitability of certain casting processes.

3. What are the key factors to consider when choosing a casting process for aerospace parts?

Key factors include component geometry, material properties, production volume, cost considerations, and quality requirements.

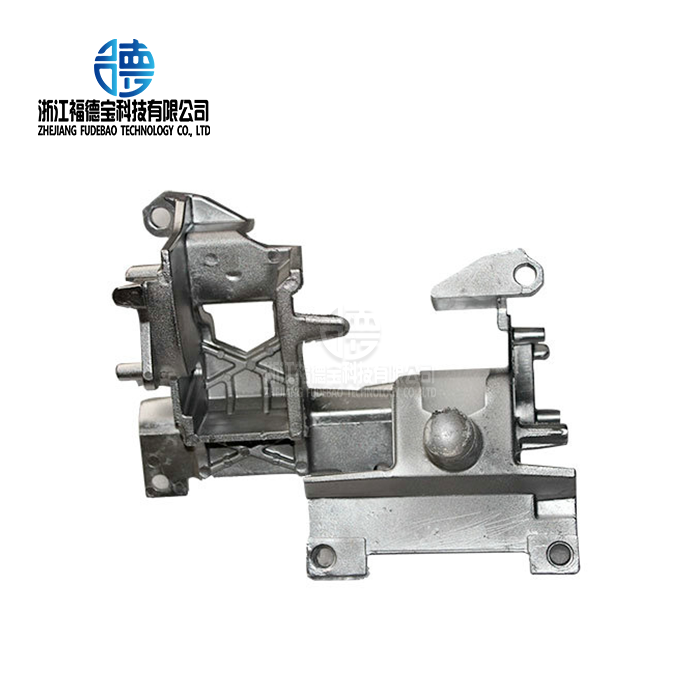

Expert Aerospace Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing high-quality casting solutions for the aerospace industry. Our state-of-the-art facilities and experienced team ensure precision, reliability, and efficiency in every component we manufacture. From investment casting to CNC machining, we offer comprehensive services to meet your specific aerospace casting needs. Contact us at hank.shen@fdbcasting.com to learn how we can support your aerospace manufacturing projects with our expert casting solutions.

References

1. Smith, J.A. (2021). Advanced Casting Technologies in Aerospace Manufacturing. Journal of Aerospace Engineering, 45(3), 267-285.

2. Johnson, M.R. & Williams, P.T. (2020). Comparative Analysis of Casting Processes for Aerospace Applications. International Journal of Materials and Manufacturing Processes, 18(2), 112-130.

3. Brown, S.L. (2019). Quality Control in Aerospace Casting: Best Practices and Emerging Technologies. Aerospace Manufacturing Technology Quarterly, 12(4), 78-95.

4. Garcia, R.E. & Thompson, K.L. (2022). Sustainability in Aerospace Casting: Balancing Performance and Environmental Impact. Green Manufacturing and Design, 7(1), 45-62.

5. Lee, C.H. (2020). Material Selection Criteria for Aerospace Casting Applications. Materials Science and Engineering: A, 795, 140023.

6.Anderson, D.R. & Miller, E.S. (2021). Economic Considerations in Aerospace Casting Process Selection. Journal of Manufacturing Economics, 33(2), 201-218.

_1756345939856.webp)

_1756344684491.webp)

_1756348489473.webp)