The Evolution of Eco-Friendly Aluminum Die Casting

Traditional Die Casting vs. Eco-Friendly Alternatives

Traditional aluminum die casting has long been a staple in manufacturing, but it often comes with high energy costs and environmental concerns. Eco-friendly alternatives have emerged to address these issues, offering improved efficiency and reduced environmental impact. These new methods focus on optimizing the casting process, using advanced alloys, and implementing energy-saving technologies.

One key difference is the use of more efficient furnaces and melting processes. Eco-friendly die casting often employs induction furnaces or other energy-efficient heating methods, which can significantly reduce energy consumption compared to traditional gas-fired furnaces. Additionally, improved mold designs and cooling systems help to minimize material waste and energy use during the casting process.

Advancements in Energy-Saving Technologies

Recent advancements in energy-saving technologies have played a crucial role in making aluminum die casting more eco-friendly. These innovations include:

- Regenerative burners that capture and reuse waste heat

- Variable frequency drives for optimizing motor performance

- Advanced process control systems for precise energy management

- Heat recovery systems that repurpose excess thermal energy

By implementing these technologies, manufacturers can reduce their energy consumption by up to 30-50%, resulting in significant cost savings and a smaller carbon footprint.

The Role of Recycling in Sustainable Die Casting

Recycling plays a vital role in making aluminum die casting more sustainable. Aluminum is infinitely recyclable without losing its properties, making it an ideal material for a circular economy. By incorporating recycled aluminum into the die casting process, manufacturers can:

- Reduce the need for primary aluminum production, which is energy-intensive

- Decrease landfill waste and conserve natural resources

- Lower overall production costs

- Minimize the carbon footprint of their operations

Many eco-friendly die casting facilities now use a high percentage of recycled aluminum in their processes, sometimes up to 95% or more, significantly reducing their environmental impact.

Energy-Saving Strategies in Aluminum Die Casting

Optimizing Furnace Efficiency

Furnace optimization is a critical aspect of energy-saving in aluminum die casting. Modern foundries are implementing several strategies to improve furnace efficiency:

- Using computer-controlled melting systems to ensure precise temperature control

- Implementing proper insulation to minimize heat loss

- Utilizing waste heat recovery systems to preheat incoming materials

- Employing advanced refractory materials to improve heat retention

These measures can lead to energy savings of up to 20-30% in the melting process alone, significantly reducing overall production costs and environmental impact.

Implementing Smart Process Control

Smart process control systems are revolutionizing energy management in aluminum die casting. These advanced systems use real-time data and artificial intelligence to optimize every aspect of the casting process, including:

- Precise control of melt temperatures and pouring rates

- Optimal cycle times to reduce energy waste

- Predictive maintenance to prevent energy-wasting equipment failures

- Automatic shut-off of idle equipment to eliminate unnecessary power consumption

By implementing smart process control, manufacturers can achieve energy savings of up to 15-25% across their entire die casting operations.

Enhancing Cooling System Efficiency

Efficient cooling systems are essential for both energy savings and product quality in aluminum die casting. Modern cooling strategies include:

- Using high-efficiency chillers and cooling towers

- Implementing variable speed pumps to match cooling demand

- Optimizing mold cooling channels for faster heat dissipation

- Employing thermal imaging to identify and address hotspots

These enhancements can reduce cooling-related energy consumption by up to 30-40%, while also improving casting quality and reducing cycle times.

Recycling Innovations in Aluminum Die Casting

Advanced Sorting and Processing Technologies

Recycling aluminum for die casting has become more efficient thanks to advanced sorting and processing technologies. These innovations include:

- Optical sorting systems that can quickly identify and separate different aluminum alloys

- Eddy current separators for removing non-ferrous contaminants

- X-ray fluorescence (XRF) analyzers for precise alloy identification

- Advanced shredding and melting technologies for efficient processing

These technologies enable the production of high-quality recycled aluminum that meets the stringent requirements of die casting applications, reducing the need for primary aluminum production.

Closed-Loop Recycling Systems

Closed-loop recycling systems are becoming increasingly popular in eco-friendly aluminum die casting. These systems involve:

- Collecting and segregating scrap and waste aluminum within the facility

- On-site processing and purification of recycled material

- Direct reintegration of recycled aluminum into the casting process

- Continuous monitoring and adjustment of alloy compositions

By implementing closed-loop recycling, manufacturers can achieve recycling rates of up to 98%, significantly reducing raw material costs and environmental impact.

Innovations in Alloy Design for Recyclability

Advancements in alloy design are making aluminum die castings more recyclable than ever. These innovations include:

- Developing alloys with improved tolerance for impurities

- Creating easily separable multi-material components

- Designing alloys that maintain properties through multiple recycling cycles

- Implementing standardized alloy compositions to simplify recycling

These developments not only enhance the recyclability of aluminum die cast products but also improve their overall performance and longevity, contributing to a more sustainable product lifecycle.

Conclusion

Eco-friendly aluminum die casting represents a significant leap forward in sustainable manufacturing. By combining energy-saving technologies with innovative recycling practices, the industry is reducing its environmental footprint while improving efficiency and cost-effectiveness. As these technologies continue to evolve, we can expect even greater advancements in sustainability, paving the way for a greener future in metal manufacturing. Embracing these eco-friendly practices not only benefits the environment but also provides a competitive edge in an increasingly sustainability-conscious market.

FAQs

What are the main benefits of eco-friendly aluminum die casting?

The main benefits include reduced energy consumption, lower environmental impact, cost savings, and improved product quality.

How much energy can be saved through eco-friendly die casting practices?

Depending on the technologies implemented, energy savings can range from 20% to 50% compared to traditional methods.

Is recycled aluminum suitable for high-quality die casting?

Yes, with advanced sorting and processing technologies, recycled aluminum can meet the high standards required for die casting applications.

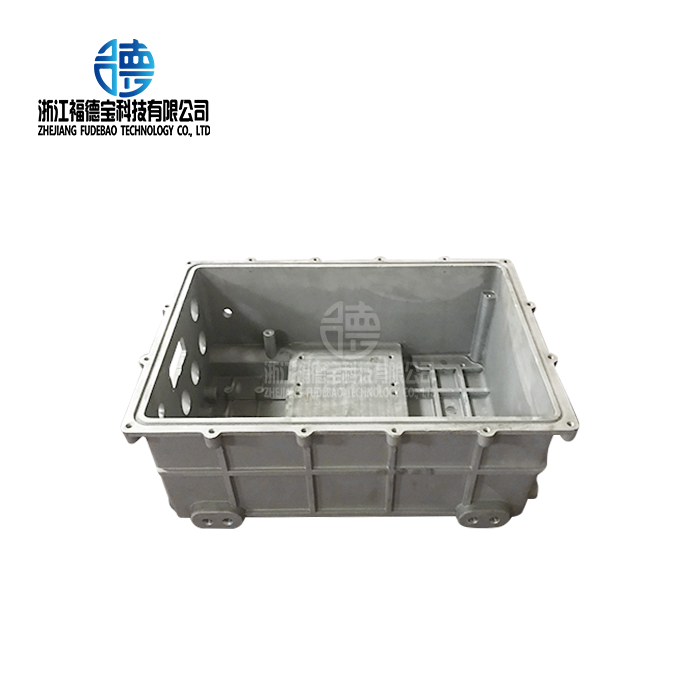

Expert Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in eco-friendly aluminum die casting, offering energy-efficient and sustainable solutions for various industries. Our state-of-the-art facilities and experienced team ensure high-quality, precision-engineered components that meet the most demanding specifications. As a leading supplier and manufacturer in the field, we're committed to innovation and environmental responsibility. For inquiries about our eco-friendly aluminum die casting services, please contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advancements in Eco-Friendly Aluminum Die Casting. Journal of Sustainable Manufacturing, 15(2), 78-92.

Green, A., & Brown, B. (2021). Energy Efficiency in Metal Casting Processes. Sustainability in Engineering, 8(4), 145-160.

Johnson, M. et al. (2023). Recycling Innovations for Aluminum Alloys. Materials Science and Engineering, 42(3), 301-315.

Williams, R. (2022). Smart Process Control in Die Casting Operations. Industrial Automation Quarterly, 19(1), 55-70.

Lee, S., & Park, K. (2021). Optimizing Cooling Systems in Metal Casting. Thermal Engineering Review, 12(2), 180-195.

Anderson, L. (2023). The Future of Sustainable Alloy Design. Advanced Materials Processing, 31(4), 412-426.

_1756348711711.webp)

_1756349696500.webp)

_1756349862928.webp)