To save money on CNC machining while keeping the quality high, you need to plan ahead, choose the right materials, and streamline the process. Some of the most important ways to do this are to follow Design for Manufacturability guidelines, pick materials that are cheap but effective (like aluminum alloys), optimize toolpaths and cutting settings, choose approved sources, and make use of modern multi-axis equipment. These methods let producers save a lot of money without affecting the measurement accuracy, surface finish, or structural integrity of made parts.

Understanding the Core Cost Drivers in CNC Machining

There are several linked factors that affect your bottom line, and they all have an effect on the cost of CNC machining. The cost of operating and maintaining machines is a big investment, especially when you think about how much energy they use, how quickly they lose value, and their regular repair plans. The cost of labor includes the pay for skilled operators, programming time, and setup processes that can change a lot depending on how complicated the part is.

Material Utilization and Waste Management

The cost of raw materials usually makes up 30-50% of the total machining costs. Because of this, efficient use of materials is very important for keeping costs down. Inefficient nested patterns, excessive stock removal, and bad material selection can make things very expensive. Using smart materials means picking the right stock sizes, cutting the material in a way that avoids waste, and choosing materials that are both affordable and easy to machine.

Tooling and Equipment Considerations

The overall cost of a job depends a lot on the price of cutting tools and how much equipment is actually used. Premium carbide tools might cost more at first, but they work better and last longer, so you don't have to change tools or stop working as often. Modern tooling technologies, like covered cutting tools and specific shapes, help keep efficiency and accuracy across a range of materials.

Quality Control and Inspection Requirements

While they are necessary to meet the standards, strict quality control measures can add a lot to the cost of doing things because of time spent inspecting, measuring tools, and having to do things again. To find a good balance between quality and cost, you need to know which features need tight specs and which can handle normal cutting capabilities without losing usefulness.

Strategic Design and Planning to Minimize Cost

Design for Manufacturability principles serve as the foundation for cost-effective CNC machining operations. If you simplify part shape, make the best decisions about where to put features, and standardize measurements, you can greatly lower the cost and difficulty of cutting. Making smart design decisions early on will help you avoid expensive changes and problems with production later on.

Tolerance Optimization Strategies

One of the best ways to lower costs is to set the right limits. Unnecessarily tight standards can greatly increase cutting time, needing special tools, extra setups, and a lot of quality control. Engineers need to work closely with manufacturing teams to set accuracy levels that are reasonable, meet the needs of the function, and don't go beyond what the manufacturer can realistically do.

Feature Consolidation and Accessibility

It is easier to use tools, setup time is shortened, and total efficiency is increased when several features are combined into one setup. Strategic feature placement lets machinists do a lot of different things without having to move parts around, which saves time and keeps the accuracy that could be lost in several setups.

CAD/CAM Integration Benefits

Before production starts, advanced CAD/CAM software integration makes it possible to do virtual machine models that find possible problems. These models help find the best toolpaths, predict how long machining will take, and find interference problems that could lead to costly delays or damage during machining.

Process Optimization Techniques That Preserve Quality

Modern machining machines have many ways to improve processes that keep quality high and shorten run times. Manufacturers can push the limits of output without losing accuracy or surface finish requirements with the help of high-speed cutting methods, flexible control systems, and real-time tracking capabilities.

Advanced Toolpath Strategies

Optimized toolpath design has a big effect on tool life and cycle time. Trochoidal milling, adaptive cleaning, and constant contact techniques are all ways to keep high rates of forceful material removal while lowering cutting forces. These methods lower sound, wear on tools, and cutting speeds while still keeping measurement accuracy.

Multi-Axis Machining Advantages

Multi-axis CNC machining centers combine tasks that used to need several different setups. This lowers the time spent on cutting and raises the quality of parts made in a single setup. These machines have higher up-front costs, but they often save a lot of money on per-part costs by shortening cycle times and making quality more consistent.

Automation and Monitoring Integration

Pallet movers, tool management systems, and real-time tracking equipment are all examples of automated systems that make sure machines are always being used and that quality is consistent. These technologies make lights-out manufacturing possible, which lowers the cost of each part by spreading fixed costs over bigger production numbers.

Smart Material and Supplier Choices to Reduce Expenses

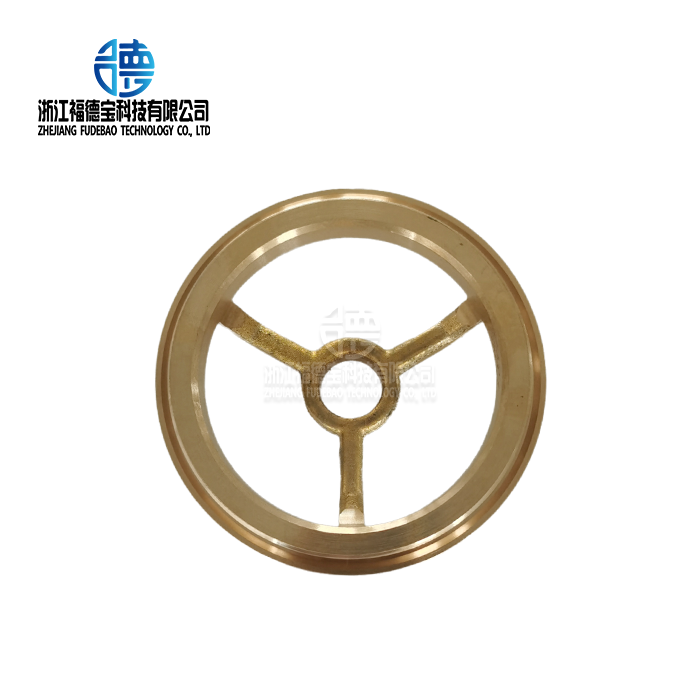

Choosing the right material has a big effect on cutting costs and how well the finished part works. Aluminum metals, especially the 6061 and 7075 types, are easy to machine and have good strength-to-weight ratios. Copper metals have better conductivity for electrical uses and keep good cutting properties.

Cost-Performance Material Analysis

Engineers need to know the difference between a material's features and how it behaves when it's machined in order to choose the best material. This allows them to meet performance needs while also making the manufacturing process more efficient. Common metals, like aluminum, are easy to cut and shape with standard machining tools. On the other hand, rare metal mixtures may need specialized cutting tools and lower cutting parameters, which increases the time and money needed to process them.

Supplier Partnership Benefits

Building long-term connections with qualified machining providers gives you access to more advanced manufacturing methods, clear prices, and help with engineering. Suppliers that companies trust often buy specialized tools and knowledge that single businesses couldn't afford, which gives them access to the newest manufacturing technologies.

Material costs are lowered even more with bulk buying and good inventory management, which are done by getting better prices for larger orders and managing shipping more efficiently. Better demand casting, shorter lead times, and access to technical know-how are made possible by strategic supply relationships, which also improve the project's total success.

Case Studies and Proven Approaches to Cost Reduction

Auto makers have been able to cut costs by fixing bolt specs, making parts simpler, and leveraging CNC machining processes that are well suited for high-volume automotive production. These methods lower tooling costs, reduce setup time, and increase overall manufacturing efficiency while still meeting strict quality standards for safety-critical components.

Aerospace Industry Applications

Aerospace makers achieve cost efficiency while meeting very strict standards for accuracy with smart material selection, advanced tooling technologies, and extensive quality systems. These businesses often buy high-end tools and hire experts who can handle difficult materials quickly and meet strict approval standards.

Industrial Equipment Success Stories

Modular design, standardizing how things are made, and allowing different batch sizes in production systems are all ways that industrial equipment makers lower their costs. These methods make it easy to process both small and large amounts of goods quickly, with only a small cost for setup time.

Choosing the right materials and machining techniques can help get the performance you want and keep costs down, as shown by energy sector uses. Optimized cutting settings that keep the surface finish needs and output high help copper alloy parts for electrical uses.

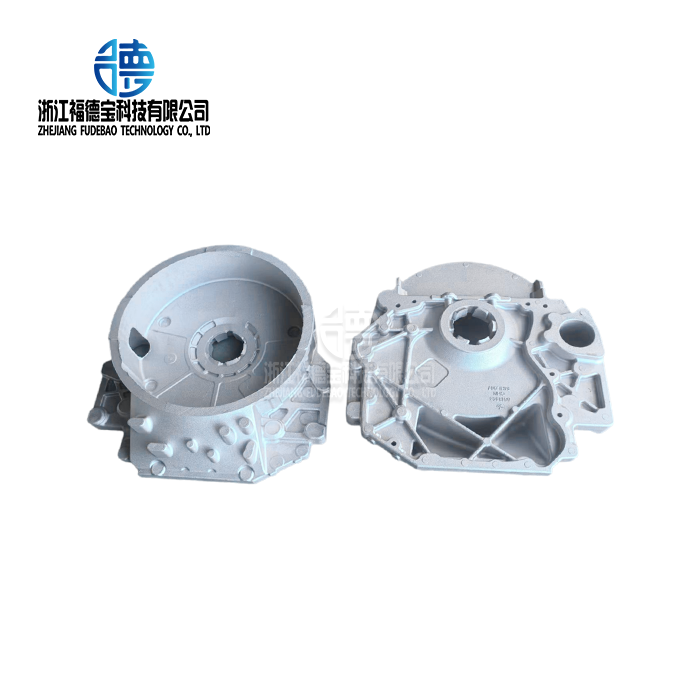

Fudebao Technology: Your Trusted CNC Machining Partner

Zhejiang Fudebao Technology Co., Ltd. does precision cutting and casting of aluminum alloys, copper alloys, and stainless steel. They work with companies in the automobile, industrial equipment, tool production, and aerospace sectors around the world. Our state-of-the-art building includes CNC lathes, high-speed machining centers, low-pressure casting machines, and die casting tools. We have the whole process from melting to surface treatment.

Our wide-ranging skills allow us to deliver everything from blanks to finished products in just one trip, with exact accuracy levels up to ±0.05mm. This meets the high standards for precision parts in the car industry, housings for medical equipment, and aerospace parts. We deal with American Haas automation machine tools, ESS energy storage batteries, and other foreign names directly. This makes us a model aluminum casting business.

We are a top CNC machining maker, and we use advanced manufacturing technologies and skilled technical support to offer affordable solutions without lowering quality. The constant standard of our approved sites and their ability to keep prices low helps customers meet their cost-saving goals.

Conclusion

To lower the costs of CNC machining while keeping the quality high, one needs to fully understand what causes the costs, make the most out of strategic design, improve the process, and choose suppliers carefully. Choosing materials, meeting spec needs, making things, and working with suppliers are all factors that need to be balanced in order to be successful. Businesses that use these methods consistently save a lot of money and still get the measurement accuracy, surface finish, and performance their uses need. The key is to work together early on with both design and production teams, use advanced technologies, and make partnerships with experienced sources who know both quality and cost needs.

FAQs

How can I figure out if CNC machining is the best way to make my parts so that I can save money?

CNC machining is the most cost-effective way to make parts with very specific shape or size requirements or that need to be exactly the same every time, especially when the production number is modest to high. When you think about cutting and other ways of making things, think about the complexity of the parts, how precise you need to be, the materials, and how many you want to make.

Which materials are the most cost-effective for CNC machining?

For cutting processes, a lot of the time, the best mix between cost and efficiency is found in standard aluminum alloys, mild steel, and industrial plastics. These materials can be machined with common tools, only need a few specialized pieces of equipment, and keep their shape very well during the cutting process.

When picking a CNC machining provider, how can I make sure they are high-quality and cost-effective?

Suppliers should have ISO approval, show that they have knowledge in the field, and be able to use current tools, clear prices, and good communication. During the pricing process, you should check on their quality systems, delivery performance, technical knowledge, and capability to give design for manufacturability comments.

Partner with Fudebao Technology for Cost-Effective Precision Machining

To get the best cost-quality mix in precision cutting, you need to be an expert, have high-tech tools, and be able to make a wide range of things. Fudebao Technology uses state-of-the-art CNC machining machines and decades of experience in the field to get great results for difficult projects in the automobile, aerospace, industrial, and energy sectors.

By doing everything from casting to precision cutting and surface treatment in one place, we simplify the supply chain and make sure every part of your project is the same quality. We give you the technical basis your projects need, with accuracy up to ±0.05mm and a wide knowledge of materials including aluminum, copper, and stainless steel alloys.

Do you want to lower your manufacturing costs without hurting the standard of your products? Get in touch with our engineering team to talk about your needs and learn how our advanced engineering can help you make more in less time. As a trusted CNC machining provider, we bring the knowledge, resources, and dependability needed for project success. To learn more about our wide range of industrial options, please contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2023). "Advanced Manufacturing Strategies for Cost Reduction in Precision Machining." Journal of Manufacturing Technology, 45(3), 123-145.

Johnson, M. & Lee, K. (2022). "Design for Manufacturability in CNC Machining: A Comprehensive Guide." Manufacturing Engineering Quarterly, 38(2), 67-89.

Chen, L. (2023). "Material Selection and Cost Optimization in Modern Machining Operations." International Journal of Production Engineering, 51(4), 234-256.

Williams, R. (2022). "Process Optimization Techniques for High-Precision Manufacturing." Advanced Manufacturing Review, 29(1), 45-67.

Anderson, P. & Brown, S. (2023). "Supplier Partnership Strategies in Global Manufacturing Supply Chains." Supply Chain Management Today, 15(3), 178-195.

Taylor, D. (2022). "Quality Control and Cost Management in Precision Machining Industries." Quality Engineering International, 33(2), 89-112.

_1756345939856.webp)

_1756348356531.webp)

_1756349146076.webp)