How to Control Porosity in Aluminum Die Casting?

2026-01-30

To control porosity in aluminum die casting, you need to use a methodical approach that includes the right melt treatment, exact process parameters, and smart design ideas. The important thing is to know that porosity is caused by stored gases and shrinkage during solidification. This can make cast parts much less reliable and affect their mechanical properties. To handle porosity well, you need to use degassing methods, keep the injection speeds and pressures at the right levels, make sure the die temperatures are just right, and make sure there are enough venting systems in place during the casting process.

Understanding Porosity in Aluminum Die Casting

One of the most constant problems in high-pressure die casting is porosity, which shows up as hollow spaces inside cast aluminum parts. During the fast solidification process, these flaws happen when trapped gases or volumetric shrinkage make holes in the final part structure that make it less strong. Because porosity creation is so complicated, you need to know a lot about metallurgical principles and how processes work in order to set up effective control measures.

Types and Characteristics of Porosity Defects

Gas porosity mostly forms when hydrogen dissolves in melted aluminum. As the aluminum cools, its solubility drops dramatically, which causes bubbles to form. Most of the time, these spherical gaps gather in thicker parts where cooling happens more slowly, making the perfect conditions for gas to form. Aluminum alloys can have more hydrogen if they are exposed to wetness, if the charge materials are contaminated, or if the furnace atmosphere is not controlled properly.

Shrinkage porosity happens when there isn't enough liquid metal left to make up for the metal's normal loss of volume as it solidifies. This type shows up as irregular, interconnected holes that are often found where parts meet or where feeding isn't good. In contrast to gas porosity, solidification modeling can predict shrinkage defects and smart design changes can be made to fix them.

Problems during the manufacturing process, like cold shuts and air trapping, can be caused by turbulent filling patterns or not enough die venting systems. These flaws hurt the integrity of the surface and cause stress points that make fatigue life much shorter. By knowing how the parameters of an injection affect the formation of defects, targeted process optimization methods can be used.

Impact on Component Performance

Porosity is directly linked to weaker mechanical qualities, especially when the material is being loaded and unloaded quickly, as stress builds up around voids and makes cracks start to spread faster. According to research, even small amounts of porosity can lower fatigue strength by 30 to 50 percent. This means that flaw control is very important for parts that are loaded and unloaded many times, like suspension parts in cars and structural elements in spacecraft.

Surface-connected porosity adds to the problems because it makes it easier for corrosion to start and makes pressure-tight uses less reliable. When used in cars, engine parts that are porous can let coolant leak out or lose their strength when subjected to thermal cycles. For electromagnetic shielding and temperature management to work properly, electronics housings need surfaces that don't have any holes in them.

Main Causes of Porosity in Aluminum Die Casting

In aluminum die casting, porosity is caused by a complicated mix of mechanical, heat, and metallurgical factors that need to be carefully controlled throughout the production process. To control porosity well, you need to pay attention to every factor that affects it, from getting the raw materials ready to solidifying the end part.

Material-Related Factors

The makeup of an aluminum alloy has a big effect on how easily hydrogen dissolves and how porous it is. The silicon content is especially important for gas retention. Alloys with more silicon usually have better flexibility, but they may need more thorough degassing to get the porosity levels that are acceptable. When modifier elements like strontium are present, they can change how solids solidify and how holes form.

Another important factor is how clean the melt is, since oxide specks and intermetallic particles can cause gas bubbles to form when the mixture hardens. Handling charge materials correctly, keeping the furnace in good shape, and using filtering systems can help lower the risk of contamination and porosity. Managing the temperature during the melting process changes how fast hydrogen is picked up and how quickly the material dissolves.

Process Parameter Optimization

Injection velocity curves directly affect how cavities are filled and how air gets trapped. Speeds that are too high can cause turbulent flow conditions that raise the risk of porosity. On the other hand, injection speeds that are too slow can cause solidification to happen too soon and filling to be incomplete, which is good for shrinkage porosity development. Modern die casting machines have complex control systems that make sure that the speed patterns are best for each part's shape.

Changing the temperature of the die has an effect on both how the material fills and how it hardens, which in turn changes the thermal gradients that control how it feeds. The right temperature control makes sure that the material solidifies in the right way and stays fluid enough to fill all the gaps. Temperature monitoring tools give feedback in real time that helps improve and standardize the process.

The design factors of the gate and runner have a big effect on how the fluid fills up and how well air escapes. Too small of gates can cause too much speed and turbulence, and systems that are too big can cause solidification to happen too soon and feeding issues. Computational fluid dynamics modeling helps make sure that gate systems fill evenly and that air doesn't get trapped too much.

Tooling and Equipment Considerations

Die venting systems are very important because they get rid of trapped air during hole filling, which stops gas-related porosity from forming. If there aren't enough vents or the vents aren't placed correctly, pressure can build up and make it hard for the system to fill properly. Ventilation systems work consistently throughout production cycles when they are maintained regularly.

The conditions of the die's surface affect how fast heat moves and how the metal flows, which in turn affects how the metal fills and hardens. Getting the die ready correctly, which includes treating the surface and adding a release agent, helps keep the temperature just right and stops solidification before it's time, which can cause pores to form. When designing and maintaining a die, it's important to think carefully about the coating's qualities and how rough the surface is.

Proven Techniques to Control Porosity

Porosity control that works needs to be done in a way that takes into account every step of the aluminum die casting process, from preparing the melt at the beginning to inspecting the finished product. Manufacturers who are good at what they do use a mix of tried-and-true methods that are tailored to their unique needs and quality standards.

Advanced Melt Treatment Strategies

Degassing activities are the main way to stop gas porosity formation, and there are different ways to lower the amount of dissolved hydrogen to a safe level. In rotary degassing devices, inert gases are pumped through spinning rotors. This makes a lot of small bubbles that trap dissolved hydrogen and make it easier to remove from the melt. How well this process works relies on how fast the gases flow, how the rotor is designed, and how long the treatment lasts.

Vacuum degassing is a better way to get rid of hydrogen, which is especially helpful for high-quality uses that need very few pores. These systems make conditions below the atmosphere that make it harder for hydrogen to dissolve and help gases come out of the melt. Combining vacuum and inert gas solutions works better for degassing than using just one technique.

Along with degassing benefits, filtration systems get rid of solid inclusions that can act as starting points for porosity creation. Controlled pore structures in ceramic foam screens catch oxide films and intermetallic particles without getting in the way of metal flow rates too much. Which filter to use depends on the properties of the alloy and the amount of cleanliness that is needed.

Process Optimization and Real-Time Monitoring

To get the best shot profile, you have to carefully change the injection velocity and pressure curves so that the space is filled evenly without too much turbulence or air getting stuck. In multi-stage injection profiles, the first filling is done slowly to make sure the flow patterns are correct. Then, the speeds are raised to finish filling before the material solidifies too soon. Process monitoring tools keep an eye on important parameters and give feedback so that improvements can be made all the time.

Thermal management systems keep the die at the right temperature during production cycles. This makes sure that the solidification process is consistent and that thermal defects are kept to a minimum. Zone-controlled heating and cooling devices let you set the temperature of different parts of a die separately, which is best for parts with specific shapes. Monitoring temperatures gives information in real time that helps control processes and make sure quality.

The vacuum-assisted die casting method is a more modern way to get rid of trapped air and stop pores from forming. During filling, these systems create sub-atmospheric conditions inside the die hole. This keeps the air from being compressed and makes it easier for all trapped gases to escape. This technology works especially well for thin-wall parts and complicated shapes that tend to trap air.

Design Considerations for Porosity Reduction

The goal of optimizing component geometry is to make sure that wall thickness is spread out evenly and that section changes are smooth so that solidification can happen in the right way and there is enough feeding. Sharp corners and sudden changes in thickness cause stress buildup and stop metal from flowing properly, which raises the risk of porosity. The best solidification patterns are achieved through gradual changes and strategic spread of materials.

The design of the gates has a big effect on how the filling moves and how holes form, so the size, location, and shape of the gates need to be carefully thought out. Using more than one gating strategy can help balance the filling and slow down the injection speed, and placing gates strategically makes sure that the solidification goes in the right way. Before making the tools, computer modeling tools help improve gating designs.

The design of the cooling system affects the rates of solidification and the temperature gradients, which in turn affects the formation of shrinkage pores and the efficiency of feeding. Conformal cooling channels placed near key sections help manage the solidification process and keep the feeding paths clear. For better temperature control, more advanced cooling methods may use heat pipes or other advanced heat transfer technologies.

Summary and Key Takeaways for Procurement and Engineering Teams

To effectively control porosity in aluminum die casting, you need to know how the material's properties, the process factors, and the design requirements of the part all interact with each other. To be successful, you need to use organized methods that deal with all the factors that affect the problem while keeping costs low and work running smoothly.

Teams in charge of buying things should give more weight to sellers who have a track record of being good at quality management systems and porosity control technologies. Some important things to look at when judging are the capabilities of the equipment, the process tracking systems, the quality certifications, and the documented track records of past porosity reduction projects that went well. Long-term relationships with highly skilled suppliers offer better value by working together to solve problems and make improvements all the time.

During the early stages of design, engineering teams must think about how to control porosity by using physical features and material choices that support the best casting conditions. When the design and manufacturing teams work together early on, they can avoid making changes that are expensive during production and make sure that the standards of the parts can still be met while still meeting quality and cost goals. Computer modeling tools let you test design ideas virtually before making the actual tools.

When you invest in modern porosity control technologies, you get a clear return on your money through lower scrap rates, more reliable parts, and happier customers. As quality standards rise and competition heats up, the business case for upgrading tools and processes gets stronger. Adopting new technologies in a smart way sets producers up for long-term success in markets that are always changing.

Company Introduction and Product & Service Overview

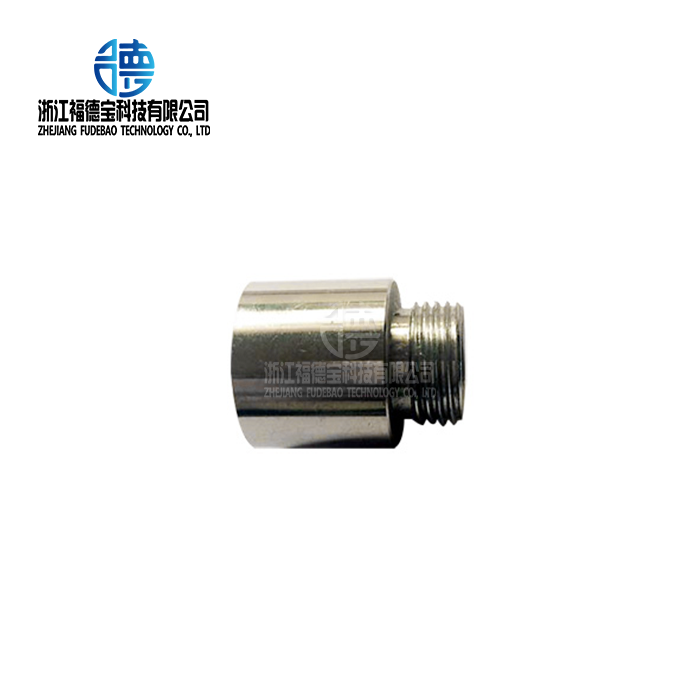

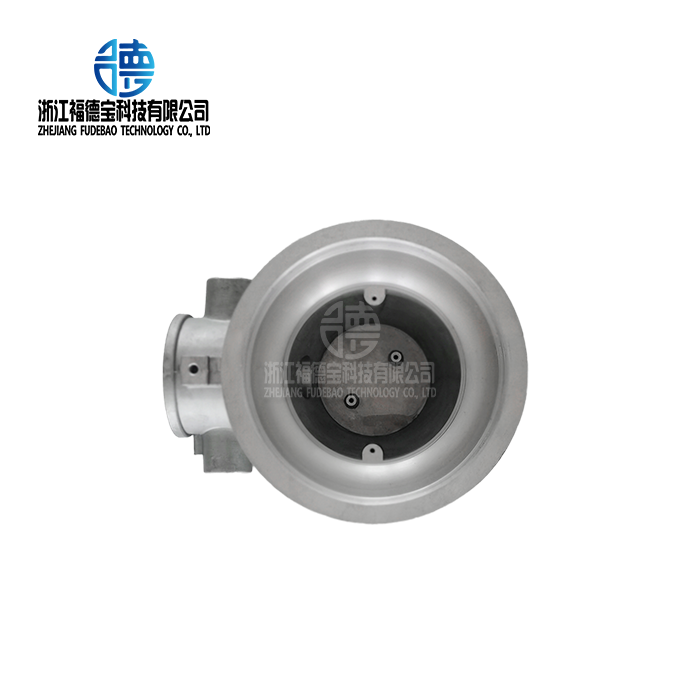

When it comes to high-precision parts for electronics, aircraft, cars, and other machines, Zhejiang Fudebao Technology Co., Ltd. is the best at making them using aluminum die casting. Our state-of-the-art facility combines cutting-edge casting technologies with full-service machining, so we can provide full solutions from the original idea to delivery of the finished product.

We have high-speed machining centers, precision CNC lathes, advanced low-pressure casting equipment, and complex die casting machines, so our technical skills cover the whole range of manufacturing needs. This unified method makes it possible to handle work flows easily and keep quality high all the way through the production process. The ability to achieve dimensional accuracy of ±0.05mm meets the strictest standards for precision in a wide range of industrial settings.

Using vacuum-assisted casting technology, advanced degassing systems, and real-time process tracking to get better part quality is what advanced porosity control is all about. Through thorough inspection methods and systematic process control, our quality management systems put a lot of emphasis on preventing porosity. This attention makes sure that parts always arrive that meet the strictest porosity requirements.

Custom OEM services offer flexible solutions that are made to fit the needs of each customer. They can help with everything from making prototypes to mass production. It is possible to speed up the development of new products with rapid prototyping while keeping costs low for low-volume uses. Our engineering team works closely with customers to make sure that plans are the best they can be in terms of quality and ease of production.

We are committed to making sure our products meet the highest standards of quality by forming strategic partnerships with foreign brands like American HAAS automation and ESS energy storage systems. Because of these partnerships, all customer applications can get access to the newest tools and best practices. We stay at the top of the aluminum foundry business by investing in new technology and making our processes better all the time.

Conclusion

To effectively control porosity in aluminum die casting, tried-and-true methods for material preparation, process optimization, and design factors must be used in a planned way. When you combine advanced technologies like vacuum assistance, advanced degassing systems, and real-time tracking, they work together to make the quality of the parts much better while keeping the costs low.

To be successful, you need to know how the properties of the alloy, how to control the temperature, the injection settings, and the design of the tool all work together. When manufacturers spend money on complete porosity control strategies, they get measurable benefits like lower scrap rates, more reliable parts, and happier customers. It makes more sense for businesses to use improved porosity control as quality standards rise across all industries.

FAQ

What causes porosity in aluminum die casting?

Porosity in aluminum die casting primarily results from trapped gases, particularly hydrogen, and volumetric shrinkage during solidification. Hydrogen dissolved in molten aluminum precipitates as bubbles when solubility decreases during cooling, while shrinkage porosity forms when insufficient liquid metal remains to compensate for natural volume reduction. Process-related factors including turbulent filling, inadequate venting, and poor thermal management also contribute to porosity formation.

Can porosity be completely eliminated from aluminum castings?

Complete porosity elimination is extremely challenging due to the inherent physics of the solidification process, but advanced control techniques can reduce porosity to industry-acceptable levels below 0.2% for critical applications. Vacuum-assisted casting, sophisticated degassing, and optimized process parameters achieve near-zero porosity in critical component areas while maintaining cost-effectiveness for less demanding applications.

How does porosity affect component performance?

Porosity significantly reduces mechanical properties, particularly fatigue strength, which can decrease by 30-50% even with small void percentages. Surface-connected porosity creates corrosion pathways and compromises pressure-tight sealing performance. In structural applications, porosity serves as stress concentration sites that accelerate crack initiation and propagation under dynamic loading conditions.

Partner with Fudebao Technology for Superior Aluminum Die Casting Solutions

Transform your manufacturing outcomes through partnership with a leading aluminum die casting supplier committed to exceptional porosity control and component quality. Zhejiang Fudebao Technology combines advanced vacuum-assisted casting capabilities with comprehensive process monitoring to deliver components meeting the most demanding specifications across automotive, aerospace, and industrial applications.

Our integrated manufacturing approach encompassing melting, casting, machining, and surface treatment ensures optimal quality control throughout the production process. Contact our engineering team at hank.shen@fdbcasting.com to discuss your specific requirements and discover how our proven porosity control expertise can enhance your product reliability while reducing total procurement costs.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

Dispinar, Derya, and John Campbell. "Porosity, hydrogen and bifilm content in Al alloy castings." Materials Science and Engineering: A, vol. 528, 2011.

Kaufman, J. Gilbert, and Elwin L. Rooy. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Schlesinger, Mark E. "Aluminum Recycling." CRC Press, 2013.

Totten, George E., and D. Scott MacKenzie. "Handbook of Aluminum: Physical Metallurgy and Processes." Marcel Dekker, 2003.

Weiss, Dieter. "Annual Book of ASTM Standards: Light Metals and Alloys." ASTM International, 2020.

_1756349071334.webp)

_1756349146076.webp)