Dimensional Stability in Aluminum Die Casting: Best Practices

2026-01-30

Dimensional stability is an important part of precision manufacturing in aluminum die casting. It refers to a part's ability to keep its exact measurements and geometric integrity during production cycles and its operating service life. This important feature makes sure that cast parts meet strict tolerance standards, which keeps them from breaking and avoids costly production delays. Modern aluminum die casting methods can achieve dimensional accuracy within ±0.05mm. This makes them essential for use in aircraft, automotive, and industrial settings where accuracy directly affects safety and performance standards.

Understanding Dimensional Stability in Aluminum Die Casting

As a general rule, aluminum cast parts must keep their stated sizes even when exposed to changes in temperature, mechanical stress, and long periods of service. This is called "dimensional stability." This stability is especially important when parts interact with other parts and need to fit and work the same way every time.

Why Dimensional Accuracy Matters in Manufacturing?

People who work in manufacturing know that differences in dimensions can lead to big problems with operations. Even small deviations from the tolerances given can make assembly harder, performance worsen, and more guarantee claims. When used in cars, engine housings and structural parts need to be very consistent in size to make sure they fit correctly and keep heat from building up. In the same way, flight parts must be very precise at all times to meet strict safety rules and performance standards.

Dimensional uncertainty has effects on the economy that go beyond the direct costs of production. When quality fails, it's common for expensive rework, stricter checking rules, and even problems in the supply chain to happen. When engineering teams invest in casting methods that are stable in terms of dimensions, they usually see less secondary machining needed and better total production efficiency.

Key Challenges in Maintaining Dimensional Precision

Industry data shows that measurement problems are mostly caused by changes in the process parameters, how the material behaves during solidification, and issues with the tools used. It is possible to predict how much aluminum alloys will shrink when they cool, but it takes a lot of skill to keep this shrinkage uniform across production runs.

Different temperatures inside casting molds cause different rates of cooling, which can cause warping and internal stresses. These problems are solved in modern foundries by using advanced mold design methods and precise temperature control systems that keep production going while reducing changes in size.

Common Causes of Dimensional Instability in Aluminum Die Casting

When manufacturers and procurement workers know what causes variations in dimensions, they can put in place targeted solutions that improve the quality and reliability of castings.

Material-Related Factors

The makeup of an aluminum die casting has a direct effect on how it casts and how stable its dimensions are. There are different ways that different alloy systems shrink, and some formulas are better at controlling dimensions than others. A380 aluminum alloy is commonly used in automotive applications. It has good dimensional stability because it has a balanced silicon content and controlled amounts of impurities.

Dimensional performance is affected by metal properties like grain structure, porosity levels, and how stress is distributed inside the material. If you choose the right alloy and follow the right steps for melting it, the material will always have the same qualities that help keep its shape during the casting process.

Process Parameter Variations

Controlling the temperature is a very important part of making sure that the dimensions stay the same. To keep shrinkage and warpage to a minimum, the injection temps, mold temperatures, and cooling rates must all be carefully controlled. Studies show that keeping injection temperatures within ±5°C of the numbers given can cut down on differences in size by as much as 30%.

Dimensional precision is also affected by the injection pressure and velocity profiles. When input speeds are too high, they can cause turbulence and air to get trapped, which can cause problems with the dimensions. If, on the other hand, there isn't enough pressure, thin-wall parts may not fill completely and have dimension gaps.

Mold Design and Maintenance Considerations

Dimensional stability is greatly affected by mold design, which includes things like the layout of the gate system, the placement of the cooling channels, and the amount of ventilation that is available. When gates are placed correctly, they create even filling patterns that reduce internal stresses and distortions of shape.

Wear, thermal cycling, and surface degradation can cause dimensions to shift over time. Regular mold care stops this from happening. Precision measurement systems keep an eye on important mold dimensions, which lets repair happen before production parts have problems with their dimensions.

Best Practices for Achieving Dimensional Stability

Using tried-and-true methods for controlling dimensions makes sure that the quality of the casting stays the same while also improving production speed and cutting costs.

Alloy Selection and Optimization

Choosing the right alloy strategically is what dimensional stability plans are built on. The A380 and A360 aluminum die casting alloys have good dimensional qualities for most uses because they have low shrinkage rates and good mechanical properties. These alloys behave the same way in sections with different thicknesses and complicated shapes.

Advanced metal modification methods, such as controlling impurities and finetuning grains, make the dimensions even more stable. Titanium-boron grain refiners make microstructures that are uniform, which reduces differences in shrinkage. Tough chemical control stops differences in size that are caused by changes in makeup.

Process Control Strategies

Temperature management systems that use real-time tracking and feedback control make sure that the right temperatures are kept during the whole casting process. Modern foundries use pyrometric systems with precise monitors placed in key areas to keep track of melt temperatures, mold temperatures, and cooling rates.

Optimizing injection parameters means making sure that the pressure, speed, and timing patterns are just right for each part's shape. Statistical process control methods keep an eye on these parameters all the time and take corrective steps when changes go beyond certain limits.

Quality Monitoring and Control Systems

At different stages of production, detailed measurement methods check that the dimensions are correct. Coordinate measuring machines (CMM) give accurate measurements, and automated inspection systems make sure that all important measures are checked during production.

Control charts and capability studies are statistical quality control methods that keep an eye on dimensional performance trends. This lets you make changes before quality problems affect customer deliveries. Most of the time, these systems get process capability indices (Cpk) higher than 1.33 for key dimensions.

Aluminum Die Casting Dimensional Stability Compared to Alternative Methods

Comparing aluminum die casting to other ways of making things shows that it has clear benefits when it comes to maintaining dimensions and being cost-effective for large-scale production.

Die Casting vs. Sand Casting

When it comes to consistency and repeatability, aluminum die casting always does better than sand casting. When sand casting, tolerances are usually within ±1.5 mm. When die casting, tolerances are usually within ±0.3 mm for most shapes. Because of this precision advantage, large secondary machining operations are not needed, which lowers the total cost of production.

Die casting also has better surface finish quality, and the surfaces that are cast as-is often meet the end requirements without any extra work. To get the same level of quality, sand casting surfaces usually need to be machined, which adds cost and complexity to the production process.

Die Casting vs. CNC Machining

CNC cutting is very accurate when it comes to dimensions, but aluminum die casting is a more cost-effective way to get precise shapes in large quantities. Die casting makes nearly net-shaped parts that don't need many extra steps, while machined parts usually need a lot of material to be removed and take longer to make.

When more than 5,000 parts are made a year, the economic crossover point usually happens. This is when the costs of die casting tools are supported by the lower costs of individual parts and the better use of materials.

Comparison with Plastic Injection Molding

Compared to plastic injection molding, aluminum die casting has better mechanical qualities and better dimensional stability at high temperatures. Plastic molding may be able to reach similar dimensional tolerances, but aluminum parts stay the same size across a wider range of temperatures and perform better in structural applications.

Aluminum alloys still have much lower thermal expansion coefficients than most industrial plastics. This means that their dimensions stay stable even when the temperature changes or when they are used at high temperatures.

Procurement Considerations for Dimensional Stability

Strategically choosing suppliers and building partnerships make sure that you can get aluminum die casting services that are stable in terms of size and meet strict quality standards.

Supplier Evaluation Criteria

Quality management systems, such as those with ISO 9001 and TS 16949 standards, make sure that measurements are controlled in a planned way and that the process can be done correctly. Advanced suppliers usually have statistical process control systems that show stable performance in terms of dimensions over long periods of time.

A supplier's dedication to dimensional excellence can be seen in the tools they have, such as modern die casting machines, precise measurement systems, and automated handling equipment. Suppliers who have both high-speed machining centers and CNC machines can offer a wide range of finishing services while keeping the dimensions of the parts the same.

Technical Capability Assessment

To judge a supplier's technical skills, you need to look at how much experience they have with related applications, the complexity of the part, and the tolerance requirements. Suppliers who have worked with cars, airplanes, or factories before are likely to know how to do the processes needed for physical stability.

Dimensional performance is heavily affected by how well the mold is designed and how well it can be made. Suppliers who make their own tools can make sure that mold designs are stable in terms of size and shape while still being able to respond quickly to changes in the designs and servicing needs.

Partnership Development Strategies

Working together with casting sources lets you make improvements all the time, which makes the dimensions more stable over time. Joint development projects that focus on process optimization, quality improvement, and cost reduction are good for everyone and make supply chain relationships stronger.

Regular technical reviews and performance evaluations make sure that the dimensions are always met and find ways to make things even better. Innovations that improve product quality and production efficiency often come from these partnerships, which are good for both suppliers and customers.

Conclusion

For aluminum die casting to be dimensionally stable, the choice of material, process control, and quality management must all be done in a planned way. When these best practices are used correctly, they make sure that high-quality parts are always made that meet strict tolerance standards and don't cost too much. When you choose the right supplier and build relationships with them, aluminum die casting's benefits in maintaining its shape make it possible to make products that are used in demanding situations in the aerospace, automotive, and industrial sectors. Aluminum die casting is now the best way to make accurate parts because of ongoing efforts to improve and new technologies that make it possible to make parts with better dimensions.

FAQ

What temperature ranges minimize dimensional variations in aluminum die casting?

Optimal injection temperatures typically range between 650°C to 700°C for most aluminum alloys, while mold temperatures should be maintained between 200°C to 250°C. These parameters minimize thermal gradients and shrinkage variations that can affect dimensional stability.

How does mold design impact dimensional accuracy?

Mold design influences dimensional accuracy through cooling channel placement, gate positioning, and venting systems. Uniform cooling prevents warpage, while proper gating ensures complete filling without creating internal stresses that compromise dimensional integrity.

What methods prevent common dimensional defects like porosity?

Preventing porosity involves controlling injection parameters, optimizing venting systems, and maintaining proper metal cleanliness. Vacuum-assisted casting techniques and degassing treatments further reduce porosity levels that can affect dimensional stability.

Which aluminum alloys provide the best dimensional stability?

A380 and A360 aluminum alloys offer excellent dimensional stability due to their balanced composition and controlled shrinkage characteristics. These alloys demonstrate consistent behavior across varying section thicknesses and complex geometries.

How can buyers ensure dimensional compliance during procurement?

Buyers should specify detailed tolerance requirements, request process capability documentation, and establish incoming inspection protocols. Regular supplier audits and performance reviews ensure ongoing compliance with dimensional specifications.

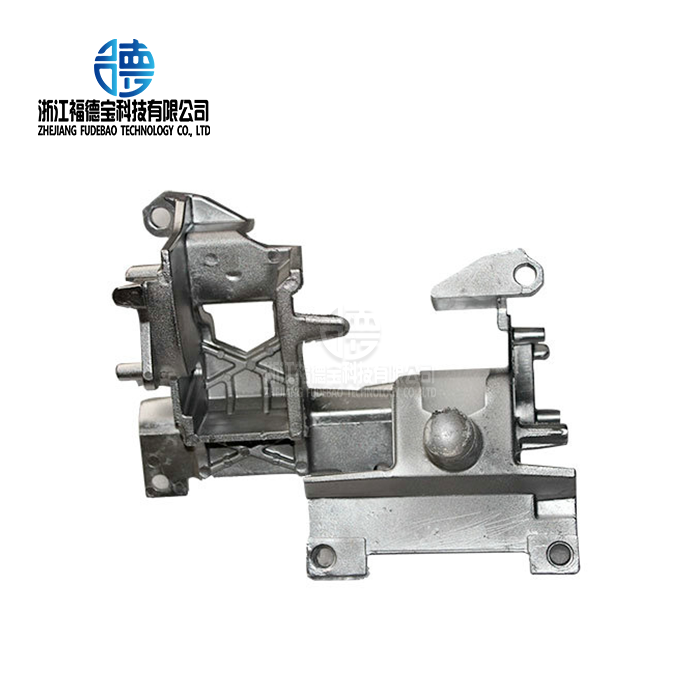

Partner with Fudebao Technology for Exceptional Dimensional Precision

Zhejiang Fudebao Technology delivers unmatched dimensional stability through advanced aluminum die casting processes and precision machining capabilities. Our state-of-the-art facility features high-speed machining centers, CNC lathes, and sophisticated die casting equipment that consistently achieve tolerances within ±0.05mm. As a leading aluminum die casting manufacturer, we serve automotive, aerospace, and industrial clients with comprehensive solutions from initial casting through final finishing operations. Contact hank.shen@fdbcasting.com to discuss your precision casting requirements and discover how our expertise can enhance your product quality and manufacturing efficiency.

References

Davis, J.R. "Aluminum and Aluminum Alloys: ASM Specialty Handbook." ASM International, Materials Park, Ohio, 2019.

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, Oxford, 2020.

Lumley, Roger N. "Fundamentals of Aluminium Metallurgy: Recent Advances." Woodhead Publishing, Cambridge, 2018.

Shivkumar, S., Ricci, S., and Apelian, D. "Influence of Solution Parameters and Simplified Practice on Tensile Properties of A356 Alloy." American Foundry Society Transactions, Vol. 127, 2019.

Wang, L., and Turnley, P. "Die Casting Process Control and Dimensional Accuracy in High-Pressure Applications." International Journal of Cast Metals Research, Vol. 34, No. 3, 2021.

Zhang, H., Liu, K., and Chen, M. "Advanced Techniques for Dimensional Stability in Aluminum Die Casting Operations." Materials Science and Engineering Technology, Vol. 52, Issue 8, 2020.

YOU MAY LIKE

_1756346259673.webp)

_1756360265131.webp)