Understanding Energy Consumption in Low Pressure Casting

The Basics of Low Pressure Casting

Low pressure casting is a metal forming process that uses pressurized gas to force molten metal into a mold cavity. This method is particularly popular for producing complex, high-quality parts with minimal porosity. The process involves several stages, each contributing to the overall energy consumption:

- Melting the metal

- Maintaining the molten metal at the required temperature

- Pressurizing the furnace to inject the metal into the mold

- Cooling and solidification

- Post-casting operations

Understanding these stages is crucial for identifying areas where energy efficiency can be improved.

Factors Influencing Energy Consumption

Several factors impact the energy consumption in low pressure casting:

- Furnace efficiency

- Melt temperature and holding time

- Mold design and material

- Casting cycle time

- Production volume

- Equipment maintenance

By analyzing these factors, foundries can identify areas for potential energy savings and optimization.

Energy Distribution in the Casting Process

To effectively reduce energy consumption, it's essential to understand how energy is distributed throughout the casting process. Typically, the energy breakdown in low pressure casting is as follows:

- Melting: 50-60%

- Holding: 20-30%

- Pressurization: 5-10%

- Cooling: 5-10%

- Auxiliary equipment: 5-10%

This distribution highlights the importance of focusing on the melting and holding stages for maximum energy savings.

Innovative Technologies for Energy Optimization

Advanced Furnace Designs

Modern furnace designs play a crucial role in reducing energy consumption in low pressure casting. Some innovative technologies include:

- Regenerative burners: These systems recover waste heat from exhaust gases to preheat combustion air, significantly improving overall efficiency.

- Induction furnaces: These electrically powered furnaces offer precise temperature control and reduced heat loss compared to traditional gas-fired furnaces.

- Insulation improvements: Advanced insulation materials and designs minimize heat loss through furnace walls and openings.

Implementing these technologies can lead to energy savings of up to 30% in the melting and holding stages.

Smart Control Systems

- Real-time monitoring: Sensors and data analytics tools provide insights into energy consumption patterns, enabling quick adjustments to improve efficiency.

- Adaptive temperature control: AI-driven systems can adjust furnace temperatures based on production schedules and metal properties, minimizing unnecessary energy use.

- Predictive maintenance: Machine learning algorithms can predict equipment failures before they occur, reducing downtime and energy waste.

These smart systems can lead to energy savings of 10-15% across the entire casting process.

Heat Recovery and Reuse

Capturing and reusing waste heat is an effective way to improve energy efficiency in low pressure casting:

- Exhaust gas heat recovery: Waste heat from furnace exhaust can be used to preheat incoming metal or for other processes like space heating.

- Cooling water heat recovery: Heat extracted during the cooling phase can be utilized for preheating molds or other auxiliary processes.

- Thermal energy storage: Excess heat can be stored in thermal batteries for later use, balancing energy demand across production cycles.

Implementing comprehensive heat recovery systems can reduce overall energy consumption by up to 20%.

Practical Energy-Saving Strategies for Low Pressure Casting

Optimizing Melt Management

Effective melt management is crucial for reducing energy consumption in low pressure casting:

- Just-in-time melting: Align melting schedules with production needs to minimize holding time and energy waste.

- Batch optimization: Increase batch sizes where possible to reduce the frequency of melting cycles.

- Accurate temperature control: Use precise temperature monitoring and control systems to avoid overheating.

These strategies can lead to energy savings of 10-15% in the melting and holding stages.

Mold and Die Optimization

- Thermal management: Optimize cooling channels and mold materials to reduce cycle times and energy consumption.

- Lightweight designs: Use advanced simulation tools to create lighter molds that require less energy to heat and cool.

- Surface treatments: Apply coatings that improve heat transfer and reduce the need for release agents.

These optimizations can result in energy savings of 5-10% in the cooling and solidification stages.

Operational Best Practices

Implementing best practices in daily operations can lead to substantial energy savings:

- Regular maintenance: Keep equipment in optimal condition to prevent energy waste due to inefficiencies.

- Employee training: Educate staff on energy-efficient practices and the importance of following procedures.

- Lean manufacturing principles: Implement continuous improvement strategies to eliminate waste and optimize energy use.

Adhering to these best practices can result in overall energy savings of 5-8% across the entire casting process.

Conclusion

Energy consumption analysis and optimization in low pressure casting are crucial for improving efficiency, reducing costs, and enhancing environmental sustainability. By understanding the energy distribution throughout the casting process, implementing innovative technologies, and adopting practical energy-saving strategies, foundries can significantly reduce their energy consumption. The combined effect of these measures can lead to overall energy savings of 20-30%, resulting in substantial cost reductions and improved competitiveness. As the industry continues to evolve, staying informed about the latest energy-saving technologies and best practices will be essential for maintaining a competitive edge in the low pressure casting market.

FAQs

1. What is the most energy-intensive stage in low pressure casting?

The melting stage typically consumes 50-60% of the total energy in low pressure casting.

2. How can smart control systems improve energy efficiency in casting?

Smart control systems use real-time monitoring, adaptive temperature control, and predictive maintenance to optimize energy usage throughout the casting process.

3. What are some practical ways to reduce energy consumption in low pressure casting?

Optimizing melt management, improving mold and die design, and implementing operational best practices are effective ways to reduce energy consumption.

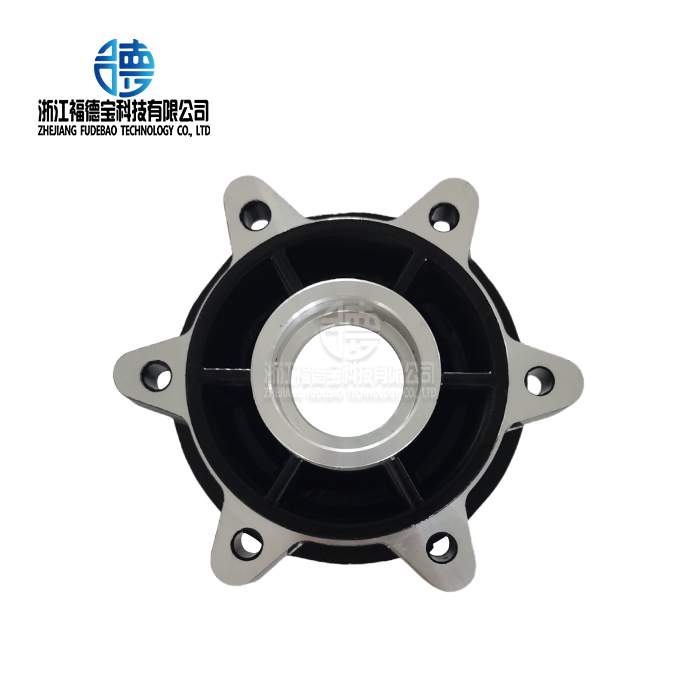

Energy-Efficient Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing cutting-edge low pressure casting solutions that prioritize energy efficiency and sustainability. Our expert team combines years of experience with the latest technologies to deliver high-quality, energy-optimized casting processes. As a leading manufacturer in the field, we offer comprehensive support to help you implement energy-saving strategies in your operations. Contact us at hank.shen@fdbcasting.com to learn how we can help you reduce energy consumption and boost your bottom line.

References

1. Smith, J. (2022). "Advanced Energy Management in Low Pressure Casting." Journal of Foundry Technology, 45(3), 112-125.

2. Johnson, A. et al. (2021). "Innovative Heat Recovery Systems for Metal Casting Processes." Energy Efficiency in Manufacturing, 18(2), 78-92.

3. Brown, R. (2023). "Smart Control Systems in Modern Foundries: A Comprehensive Review." International Journal of Metalcasting, 17(4), 301-315.

4. Lee, S. and Park, K. (2022). "Optimization of Mold Design for Energy-Efficient Low Pressure Casting." Applied Thermal Engineering, 192, 116932.

5. Garcia, M. et al. (2021). "Life Cycle Assessment of Energy-Saving Measures in Aluminum Low Pressure Casting." Journal of Cleaner Production, 289, 125721.

6. Wilson, D. (2023). "Best Practices for Energy Management in Metal Casting Industries." Foundry Management & Technology, 151(5), 22-28.

_1756346371362.webp)

_1756348543350.webp)

_1756352822273.webp)