How to Choose a Reliable Copper Casting Supplier?

2026-01-30

To find the best copper casting supplier, you need to look at their quality certifications, production skills, and how reliable their supply chain is. The best copper castings come from companies that follow ISO standards, offer a range of alloys, and consistently meet the required dimensions. To make sure your procurement needs are met by operational needs and project deadlines, you should pay close attention to technical knowledge, delivery performance, and customer support.

Understanding the Copper Casting Market and Its Challenges

The copper casting business includes many different ways to make things, such as sand casting and precision investment casting. Each is best for a certain type of use in the automotive, industrial machinery, electrical, and aerospace industries. Copper alloys today are very good at conducting heat, resisting corrosion, and having mechanical qualities that make them necessary for important parts like electrical housings, heat exchangers, and structural elements.

However, procurement workers often face big problems when they try to find copper cast components. Quality problems are still a big problem because changes in the alloy's make-up, the casting conditions, and the rate at which it cools can affect the accuracy of measurements and the material's qualities. Most of the time, these differences are caused by process controls, quality management systems, or equipment that hasn't been properly calibrated.

Common Market Challenges

Disruptions in the supply chain are another major problem that can delay deliveries and projects. Changes in the availability of raw materials, delays in transportation, and limits on capacity can all have a big effect on production plans. This is especially true for high-volume automotive applications or time-sensitive aerospace projects. When buyers understand these market dynamics, they can make backup plans and build relationships with providers who show supply chain resilience.

Compliance with certification adds to the difficulty, especially in fields with strict quality standards. Suppliers to the car industry must meet IATF 16949 standards, while aerospace manufacturers need AS9100 certification. UL compliance is often needed for safety-critical uses by companies that make electrical equipment. To meet these certification needs, suppliers must have complete quality control systems and written traceability procedures.

Essential Criteria to Evaluate When Choosing a Copper Casting Supplier

Evaluating possible copper castings sources needs a methodical approach that takes into account a number of important factors that affect the success of the procurement. Quality assurance is the basis of evaluating suppliers. It includes things like ISO 9001 approval, ASTM compliance, and industry-specific standards that make sure products always work the same way. The best suppliers have documented quality management systems that include statistical process control, inspection of incoming materials, and detailed testing methods.

Being technically skilled in a number of different casting ways gives you the freedom to meet a wide range of application needs. For large parts, sand casting is a cost-effective option. For precise uses, investment casting provides a better surface finish and more accurate dimensions. When it comes to structural parts, low-pressure casting gives them great mechanical qualities, and centrifugal casting makes sure that the material density is just right for rotating equipment.

Production Capabilities and Scalability

Production scalability means that the company can handle different order sizes while still meeting quality standards and meeting delivery deadlines. Aerospace makers need flexible batch production with a lot of documentation, while automotive suppliers need the ability to make a lot of parts at once with consistent cycle times. For new product development cycles, industrial equipment uses often need custom alloy development and the ability to make quick prototypes.

The supplier's worth goes beyond making raw castings because it can also do advanced machining. Suppliers can send finished parts with tight tolerances thanks to CNC machining centers, precision grinding equipment, and coordinate measuring tools. Surface treatment options, such as plating, anodizing, and coating applications, add value and make it easier for buyers to handle the supply chain.

Some success indicators for delivery are consistent lead times, rates of on-time delivery, and accurate order fulfillment. Reliable suppliers keep extras of standard parts on hand as a safety net, offer faster production choices for urgent needs, and are open about when they will be producing things. Flexibility in the minimum order number meets the needs of both developing prototypes and increasing production levels.

Comparing Copper Casting Suppliers: What Differentiates the Best?

The best copper castings suppliers stand out by having verified track records that show consistent performance across a wide range of customer relationships and business applications. Client references from well-known automakers, rocket manufacturers, or industrial equipment makers can tell you a lot about a supplier's dependability, technical skill, and ability to solve problems. The most trustworthy providers are happy to share case studies that show how they've worked with others successfully and achieved technical goals.

Geography has a big effect on how well logistics work, how much shipping costs, and how quickly the supply chain can respond. When it comes to communication, quality control, and lower transportation risks, domestic suppliers are better than international ones. However, foreign suppliers may offer lower costs and more specialized services. To find the best supplier location tactics, it's helpful to look at the total cost of ownership, which includes things like transportation, inventory costs, and quality risks.

Customer Service Excellence

Excellent customer service includes proactive communication, technical help skills, and working together to solve problems. The best suppliers give each customer a personal account manager who knows what the customer needs, keeps in touch with them regularly, and coordinates cross-functional support teams. As part of technical support, you can get help with metallurgy, design optimization, and failure analysis, all of which are very useful for more than just production.

Quick response times for quotes, correct pricing structures, and clear cost breakdowns make it easier to make good procurement decisions. Leading suppliers give detailed technical proposals, tips for different materials, and value engineering ideas that meet both performance and cost goals. Their purchasing departments like suppliers that offer flexible payment terms, discounts for large orders, and long-term price deals that help with strategic planning.

Company Introduction and Product & Service Information

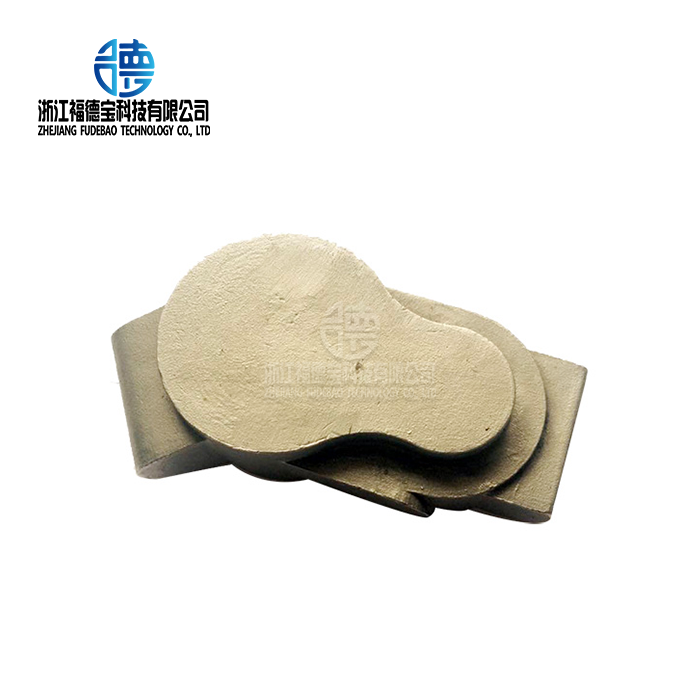

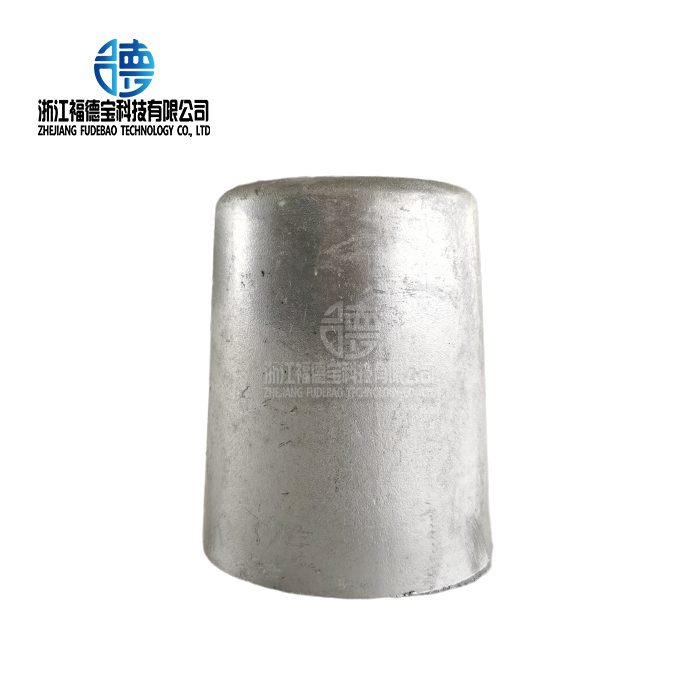

Zhejiang Fudebao Technology Co., Ltd. is a leading company that casts metal and machines it precisely. They specialize in making copper alloy parts, as well as parts made of aluminum and stainless steel. Through advanced production technologies and strict quality control systems, we serve the global automotive, industrial equipment, aerospace, and electrical industries with all of our manufacturing services. We used to work with foreign brands as middlemen, but now we work directly with them as suppliers. For example, American brands HAAS automation machine tools and ESS energy storage systems are now our partners.

Our modern building has core machines like high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting systems that allow the whole process to be integrated, from melting to finishing. This all-around method allows for one-stop delivery of blank casts and finished parts, with dimensions accurate to within 0.05 mm, which meets the strict needs of precision parts for cars, medical equipment housings, and electrical parts.

Advanced Manufacturing Capabilities

Surface treatment options include anodizing, plating, and special finishes that make things look better and make them less likely to rust. Our quality management system includes methods for inspecting incoming materials, keeping an eye on work in progress, and final inspections. It is supported by coordinate measuring machines and metallurgical analysis equipment. We are committed to using environmentally friendly production methods, as shown by our environmental certificates and sustainable manufacturing practices.

As part of technical support services, you can get help with metallurgy, design optimization, and making quick prototypes that speed up the product creation process. Our engineering team works with customers to choose the best alloy, improve casting designs, and make the production process better so that customers can get the best performance and lowest costs. Flexible minimum order amounts can be used for both developing prototypes and making a lot of them at once, and delivery performance is always the same.

Conclusion

To find the best copper castings supplier, you need to carefully look at their quality systems, technical skills, and customer service that meet your needs. The best relationships are formed with suppliers who consistently meet their obligations, communicate effectively, and work together to find solutions to problems that support the company's long-term goals. Procurement teams can build relationships with suppliers that improve organizational efficiency and give them a competitive edge by focusing on certified quality standards, advanced manufacturing capabilities, and responsive customer service. Putting in the time and effort to carefully evaluate suppliers pays off in lower quality risks, better delivery performance, and more reliable products.

FAQ

What casting methods are most suitable for complex copper component geometries?

Investment casting provides superior dimensional accuracy and surface finish for intricate geometries with thin walls and detailed features. This process accommodates complex internal passages, undercuts, and fine details that would be difficult or impossible with other casting methods. Sand casting remains cost-effective for larger components with moderate complexity, while low-pressure casting offers excellent mechanical properties for structural applications requiring strength and reliability.

How do copper alloys compare to alternative materials for electrical applications?

Copper alloys offer exceptional electrical conductivity, thermal management, and corrosion resistance that make them ideal for electrical housings, motor components, and power distribution equipment. Bronze alloys provide enhanced wear resistance for mechanical applications, while brass offers excellent machinability and aesthetic appeal. Material selection depends on specific performance requirements including conductivity, strength, corrosion resistance, and environmental conditions.

What are typical lead times for custom copper casting orders?

Standard copper castings typically require 2-4 weeks for production, while custom alloys or complex geometries may extend to 6-8 weeks depending on tooling requirements and order quantities. Rapid prototyping services can deliver sample parts within 1-2 weeks for design validation. High-volume production orders benefit from dedicated production scheduling that ensures consistent delivery performance and inventory management support.

What quality certifications should I expect from reliable suppliers?

Reputable copper casting suppliers maintain ISO 9001 quality management certification as a minimum standard, with industry-specific certifications including IATF 16949 for automotive applications, AS9100 for aerospace components, and UL compliance for electrical equipment. Material certifications should include chemical analysis reports, mechanical property verification, and dimensional inspection documentation. Traceability systems ensure complete documentation from raw material receipt through final delivery.

Partner with Fudebao Technology for Superior Copper Casting Solutions

Discover how Fudebao Technology can optimize your copper castings procurement strategy through our advanced manufacturing capabilities and customer-focused service approach. Our experienced engineering team provides comprehensive technical support, from alloy selection to design optimization, ensuring your components meet exact specifications and performance requirements. Contact hank.shen@fdbcasting.com to discuss your specific requirements and receive detailed technical proposals that demonstrate our value proposition as your preferred copper castings supplier.

References

American Foundry Society. "Copper and Copper Alloy Casting Handbook: Manufacturing Processes and Quality Standards." Des Plaines: AFS Publications, 2023.

International Copper Association. "Technical Guide to Copper Casting Applications in Industrial Manufacturing." New York: ICA Research Division, 2022.

Society of Manufacturing Engineers. "Advanced Casting Technologies for Metal Components: Industry Best Practices and Quality Management." Dearborn: SME Press, 2023.

ASM International. "Copper and Copper Alloys: Properties, Processing, and Applications in Modern Manufacturing." Materials Park: ASM Handbook Committee, 2022.

North American Die Casting Association. "Quality Assurance Standards for Non-Ferrous Metal Castings in Automotive Applications." Wheeling: NADCA Technical Publications, 2023.

Institute of Cast Metals Engineers. "Supplier Selection Criteria for Critical Casting Applications: A Comprehensive Evaluation Framework." Birmingham: ICME Professional Development Series, 2022.

_1756345939856.webp)

_1756346613780.webp)

_1756349696500.webp)

_1756350092126.webp)