Post-Casting CNC Machining: From Rough Casting to Precision

2026-01-29

Post-casting CNC machining is the key to making the transition from rough, unfinished castings to precisely made parts that meet strict industry standards. This high-tech way of making things uses computer numerical control to carefully remove material from cast parts. This gives them precise measurements and smooth surfaces that raw castings can't provide. Adding CNC machining after casting has changed the way manufacturers make parts. It lets them use the cost-effectiveness of casting while getting the precision needed for modern engineering applications in the aerospace, automotive, and industrial sectors.

Understanding Post-Casting CNC Machining

Defining the Role of Precision Finishing

Post-casting CNC machining is an important finishing step that turns rough casts into precise parts that are ready for tough jobs. This change solves the main problem that procurement professionals have when they need to find parts that meet strict performance standards while also being efficient for making. The process carefully gets rid of the flaws in the material, differences in size, and rough surfaces that are common in raw casts.

Rough casts often have uneven surfaces, different sizes, and different amounts of material. This is because of how the casting process works. Even though these traits are fine for the first stage of shaping, they need to be improved to meet the exact requirements of current engineering uses. CNC machining gets around these problems by removing material automatically and according to a program. This makes sure that the process is repeatable and consistent across production runs.

Material Considerations and Machining Parameters

Understanding the specific properties of the material that affect tool choice and process factors is very important for post-casting precision machining to work well. Many things in the car and aerospace industries use aluminum alloys because they are easy to machine and don't cut too hard, so they can be used at high speeds. These materials work well with sharp carbide tools and the best cutting settings that get rid of the most material while keeping the quality of the surface.

Steel metals are harder to machine because they need strong tooling strategies and carefully controlled cutting parameters to keep heat from building up and tool wear from happening. Because steel castings are naturally strong and hard, they need special methods that balance productivity with tool life. This is especially important in high-volume production settings where stability is very important.

Copper alloys are very important in electrical and energy uses, but they are hard to machine and need special shapes for the tools and ways to use cutting fluid. The temperature and electrical conductivity of these materials affect how heat is lost during machining, which in turn affects the quality of the surface finish and the stability of the dimensions throughout the process.

The Post-Casting CNC Machining Process - Step by Step

Initial Inspection and Process Planning

The first step in the post-casting machining process is to carefully look over the rough casts to find any flaws in the material, differences in size, or rough surfaces that might affect the next steps in the process. During this part of critical assessment, machining allowances, tool path planning, and quality control checkpoints are set up to make sure the change from rough casting to precision component goes smoothly.

To map the geometry of a casting and set reference datums for later machining operations, skilled workers use a variety of measuring tools, such as coordinate measuring machines and optical scanning systems. This information guides CNC machining code choices, the choice of tools, and the design of fixtures, all of which affect the success of the process and the quality of the parts that come out of it.

CNC Programming and Tooling Strategies

To set a CNC for post-casting tasks, you need to know a lot about how materials behave, how they cut, and what tools can do that makes this process different from regular machining. Programmers have to think about problems that only happen in casting, like changes in the hardness of the material, the presence of inclusions, and surface flaws that can affect how well the tool works and the quality of the part.

During the programming process, there are usually more than one machine pass. Each pass is meant to handle a different part of the change from rough casting to precision component. Roughing passes get rid of a lot of material quickly while setting up the basic shape, and semi-finishing steps smooth out the sides and get closer to the final size. Finishing passes make sure that the finished dimensions and surface finish meet the requirements of the component.

Quality Control and Tolerance Verification

During the post-casting machining process, quality control methods make sure that the parts are intact and meet the engineering specifications for size and shape. Real-time measurement systems, statistical process control, and automatic inspection technologies are used in modern factories to keep an eye on important dimensions and surface features while they're being made.

These quality assurance methods allow process changes to be made right away when variations happen. This keeps production running smoothly and stops parts from being defective. When measurement input is added to CNC programming, closed-loop systems are made that automatically fix problems like tool wear, thermal effects, and material changes that could lower the quality of the parts.

Comparing Post-Casting CNC Machining with Alternative Methods

CNC Machining versus Manual Machining Approaches

When it comes to speed, accuracy, and scalability—the three things that modern manufacturers look at—post-casting CNC machining clearly beats manual machining. Even though manual cutting is useful for making prototypes and fixing things, it isn't repeatable or consistent enough for mass production. When people do things by hand, there is some variation that can happen. This can be a problem as tolerances get tighter and production numbers rise.

CNC systems get rid of the variability of the operator and make it possible to make complicated shapes and features that would be hard or impossible to make by hand. CNC operations can be programmed to make sure that each component has the same properties across production runs. This helps quality control systems and meets the requirements for traceability that modern supply chains need.

Alternative Manufacturing Technologies

Three-dimensional printing and injection casting are two different ways to make parts, and each has its own benefits in certain situations. Additive manufacturing works great for fast prototyping where speed of design changes is more important than low production costs. In high-volume industrial settings, however, 3D printing can't be used because of limits on materials, surface finish, and production rate.

Injection molding gives polymer parts smooth surfaces and consistent sizes, but it can only be used for certain tasks because of limitations in the materials that can be used and the cost of the tools that are needed. When it comes to demanding automobile, aerospace, and industrial uses, the thermal and mechanical properties of injection-molded parts don't always match those of cast and machined metal parts.

When procurement teams choose manufacturing methods based on project size, cost-effectiveness, and quality needs, they do better when they understand these technology trade-offs. After casting, CNC machining is the only way to get uniform, high-precision finishes that can be relied on in high-volume production settings where material properties and dimensional accuracy are both very important.

How to Choose the Right CNC Machining Services for Post-Casting Needs?

Evaluating Supplier Capabilities and Experience

Selecting an expert machining supplier requires careful assessment of demonstrated experience with casting-specific challenges and proven capability to maintain tight tolerances consistently. Suppliers who are qualified know a lot about how materials behave, how to make tools that work best, and how to make the process run more smoothly. These are the things that make post-casting uses different from regular machining tasks.

Certifications in the industry, quality control systems, and customer references are all great ways to find out about a supplier's skills and dependability. ISO 9001 certification shows that you follow the rules for quality management, and industry-specific certifications, like AS9100 for aerospace uses, show that you know how to work in tough manufacturing environments.

Supplier Selection Criteria and Trade-offs

When choosing between local machine shops and bigger contract manufacturers, you need to look at a number of things, such as lead times, cost structures, and the ability to handle different order volumes. Larger manufacturers usually have more modern equipment, more thorough quality systems, and the ability to make a lot of products. Local suppliers usually have shorter wait times and more personalized service.

Procurement professionals can figure out how much a project really costs by looking at more than just the starting price. The total cost of a project can be affected by things like setup fees, amortization of tools, material handling, and quality paperwork. These factors are especially important for smaller orders or shapes that are hard to fix.

A technical capability assessment should look at things like the specs of the equipment, how well it can measure things, and the process control systems that make sure quality output is always the same. Advanced factories buy multi-axis machining centers, automated measurement systems, and environmental controls that help them meet the precise production needs of a wide range of materials and applications.

Company Introduction and Our Post-Casting CNC Machining Solutions

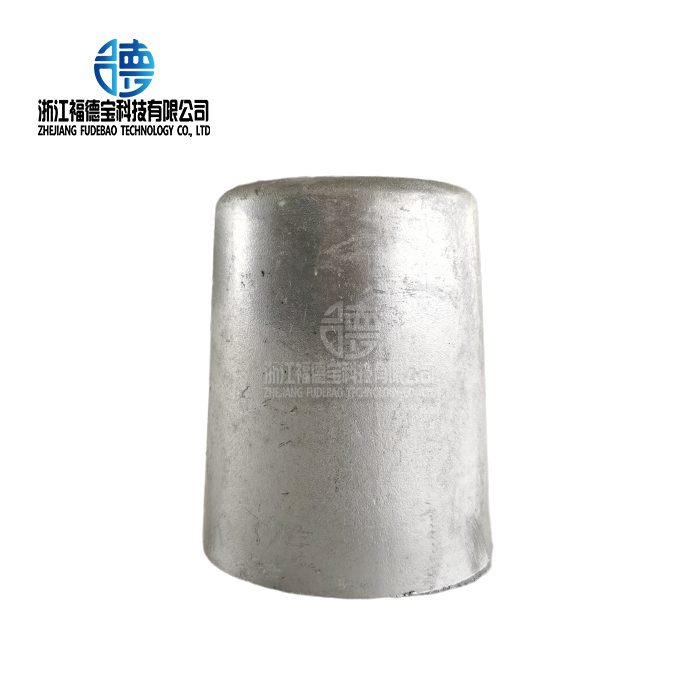

Because it has been specializing in post-casting CNC machining for decades, Zhejiang Fudebao Technology Co., Ltd. has become a top partner for precision production. We can make everything, from melting and casting to precise machining and surface treatment. This means that we can offer one-stop delivery options that make the supply chain simpler for clients around the world.

High-speed machining centers, CNC lathes, low-pressure casting machines, and die casting systems are just some of the high-tech tools in our production facility that help turn raw materials into finished, precise parts. This unified method gets rid of the handoff delays and quality risks that come with using multiple vendors to make things. It also makes it possible to optimize the whole process, which is good for both cost and quality.

Advanced Manufacturing Capabilities

Our integrated manufacturing method has many benefits, but the main ones are accuracy, consistency, and the ability to grow to meet the changing needs of clients in the automotive, aerospace, industrial, and energy sectors. Our cutting operations can keep tolerances of up to ±0.05mm while keeping production costs low for both prototypes and large-scale production.

Our technical team has a lot of knowledge with materials like stainless steel, copper alloys, and aluminum alloys that are often used in tough situations. This knowledge of the material allows for the most efficient processing methods that boost output while maintaining the quality and consistency of parts across production runs.

Quality certifications and long-term partnerships with foreign brands, such as direct supply partnerships with American brands like ESS energy storage batteries and HAAS automation machine tools, show that we are dedicated to making the best products and making sure our customers are happy. These agreements show that we can meet the high standards needed for global supply relationships to work.

Conclusion

Post-casting CNC machining is a sophisticated way to make things that successfully bridges the gap between casting methods that are low-cost and the precision needs of modern engineering uses. Manufacturers can use casting's material efficiency to get accurate measurements and surface finishes that meet strict industry standards with this integrated approach. As engineering standards keep changing to require tighter tolerances and better performance in the automobile, aerospace, and industrial sectors, this process is becoming more and more important. To make sure the implementation goes well, the characteristics of the materials, the improvement of the process, and the selection of suppliers must all be carefully thought out so that they meet the needs of the project and the quality goals.

FAQ

What tolerance ranges can be achieved through post-casting CNC machining?

Modern post-casting precision machining operations routinely achieve tolerances ranging from ±0.05mm to ±0.1mm depending on material characteristics, component geometry, and specific machining strategies employed. These tolerance capabilities significantly exceed those achievable through casting alone, enabling component applications in precision-critical environments such as automotive engines, aerospace structures, and precision industrial equipment.

How does precision machining improve cast part strength and durability?

Precision machining enhances cast component performance by removing surface imperfections, stress concentrations, and material inconsistencies that can compromise structural integrity. The process eliminates casting-related defects while creating uniform surface finishes that improve fatigue resistance and dimensional stability under operating loads.

Can you handle both prototype and volume production requirements?

Our manufacturing capabilities encompass both rapid prototyping for design validation and scalable volume production that supports ongoing supply requirements. Flexible order management systems enable seamless transitions from prototype through production phases while maintaining consistent quality standards and delivery performance across varying order volumes.

Partner with Fudebao Technology for Superior CNC Machining Solutions

Manufacturers seeking reliable post-casting precision machining partnership will discover comprehensive capabilities at Fudebao Technology, where advanced equipment and experienced technical teams deliver exceptional results consistently. Our integrated manufacturing approach, spanning casting through final machining, provides unique advantages in quality control, lead time optimization, and cost effectiveness. Connect with our engineering team at hank.shen@fdbcasting.com to discuss your specific requirements and discover how our CNC machining manufacturer expertise can enhance your project outcomes and supply chain performance.

References

Thompson, R.J. "Advanced Post-Casting Machining Techniques in Modern Manufacturing." Journal of Precision Manufacturing Technology, Vol. 45, No. 3, 2023, pp. 78-92.

Chen, M.L. and Williams, P.K. "Material Considerations for CNC Machining of Cast Aluminum Components." International Conference on Manufacturing Processes, 2023, pp. 156-171.

Rodriguez, A.M. "Quality Control Strategies in Post-Casting CNC Operations." Manufacturing Engineering Quarterly, Vol. 28, No. 4, 2023, pp. 34-48.

Johnson, K.D. "Economic Analysis of Integrated Casting and Machining Processes." Industrial Manufacturing Review, Vol. 19, No. 2, 2023, pp. 112-127.

Liu, S.H. and Anderson, J.R. "Tolerance Achievement in Multi-Stage Manufacturing Operations." Precision Engineering Journal, Vol. 52, No. 1, 2023, pp. 89-104.

Brown, T.L. "Supplier Selection Criteria for Complex Manufacturing Partnerships." Supply Chain Management Today, Vol. 31, No. 6, 2023, pp. 45-62.

_1756346668222.webp)

_1756348300182.webp)

_1756352400994.webp)