CNC machining technology changes the way parts for electric vehicles are made by providing the accuracy, speed, and dependability that today's EV production needs. CNC machining lets makers make complicated shapes with exact specifications. It also helps them keep quality high across all production runs, thanks to computer-controlled robotics and advanced tools systems. This way of making things directly meets the strict needs of parts for electric vehicles, from battery housings to motor assemblies. This makes it an important technology for car OEMs and suppliers who are dealing with the quickly changing world of electric transportation.

Understanding CNC Machining in EV Component Manufacturing

Computer numerical control (CNC) machining is a very important technology in the creation of electric car parts. CNC machining uses automated processes to make very accurate parts with tools that are managed by computers. This way of making things has become very important for making the hard-to-get parts that today's electric cars need.

Core Technologies and Machine Types

Multi-axis milling centers are very important to the production of electric vehicles' parts because they can be used to make the complex shapes that are needed for motor housings and battery casings. These machines can work on five or more directions at the same time. This makes it possible to make complicated parts in just one setup while keeping the measurement accuracy within ±0.05mm limits. CNC lathes help cutting operations by making motor shafts, electrical connections, and other round parts with very smooth surface finishes.

Material Capabilities for EV Applications

CNC machining can give the electric car parts they need by using materials with the right qualities. Aluminum metals are good at managing heat because they are light, strong, and able to carry electricity. Copper alloys are very important for electrical uses because they have better conductivity than other metals for motor windings and parts of the charging infrastructure. Stainless steel versions prevent rusting, which is important for battery safety systems and parts on the outside that are open to the elements.

Challenges in EV Component Development and CNC Machining Solutions

Making electric vehicles requires advanced manufacturing methods because it comes with problems that are not seen in other industries. The complexity of current electric vehicles makes it hard to integrate materials, make parts that fit perfectly, and be able to change the way you make things on the fly.

Complex Geometry Requirements

Today's electric cars have parts with complex inner workings, like cooling pathways in battery packs and complicated airflow paths in motor housings. These shapes are hard for traditional manufacturing methods, but multi-axis CNC can make internal features and complicated surfaces that make things work better. Being able to make parts from solid blocks of material gets rid of assembly joints that might hurt the strength or heat management of the structure.

Rapid Prototyping and Development Cycles

Because electric vehicles are being developed more quickly, we need ways to make working prototypes quickly from design ideas. In this setting, CNC machining works great because it doesn't need the tools that are common in other ways of making things. Within days, engineers can go from CAD models to real-life versions. This lets them quickly make changes and check that the plans for each part work. This agility is very important when making parts for new battery technologies or new ways to use motors.

Quality and Precision Standards

Parts for electric vehicles need to be made in a way that meets the general quality standards of the car industry and also takes into account the safety needs of high-voltage systems. CNC machining keeps the surface finishes needed for electrical parts and makes sure that the dimensions are exactly right for a good fit and function. Computer-controlled manufacturing has process control built into it, which guarantees that production runs are the same every time. This helps meet the quality paperwork needs of car supply chains.

Key CNC Machining Processes and Their EV Applications

In the making of parts for electric vehicles, different CNC processes are used to meet different needs. Each process adds something special to the total production system.

Precision Milling for Motor Components

Motor housings need to have very exact bearing surfaces and complicated cooling shapes that are made possible by CNC cutting. The process makes the right fixing areas for rotor parts and adds air features that help control heat. CNC processes that keep the tight specs needed for the best magnetic field properties and power transfer are good for stator parts.

Turning Operations for Rotational Components

Motor shafts and rotor units need the surface finishing and precise precision that CNC turning can give them. These parts work at high speeds of spinning while carrying heavy mechanical and magnetic loads. They need to be made in a way that ensures regular concentricity and surface quality. CNC turning can get a very high level of accuracy. This makes sure that the bearings fit correctly and the machine doesn't vibrate too much when it's running.

Specialized Machining for Battery Systems

It is important for the ways that battery casings and heat control parts are made to take into account both how they will be used and how they will be built. CNC cutting makes exact designs for cooling channels that help heat move while keeping the structure strong. The process makes it possible to build lightweight designs that improve heat performance without lowering safety for fragile battery cells.

Optimizing CNC Machining for EV Component Performance and Cost Efficiency

Using CNC technology correctly means finding a balance between performance needs and the costs of making.

Design for Manufacturability Integration

When the design and manufacturing teams work together, they can make sure that the shapes of the parts are suitable for CNC production and that the parts still work the way they are supposed to. If you design things so that they work with standard tools, it makes making easier and cheaper. When CAD and CAM processes are combined, design meaning is sure to be correctly passed on to production directions. This lowers the chances of making mistakes and speeds up the development process.

Optimizing manufacturing doesn't just focus on single parts; it also looks at how they are put together and the processes of the supply chain. It is easier to set up and build parts that are made with uniform data standards, which makes production more efficient. If you choose a material based on machinability and practical needs, it can have a big effect on the cost of production without hurting performance.

Process Comparison and Selection

For many EV uses, CNC machining is better than other industrial methods in certain ways. Even though 3D printing can make very complicated shapes, CNC machining gives important parts smoother surfaces and better accuracy. Casting methods might be cheaper for high-volume production, but they don't have the freedom needed for quick design changes that are common in EV development.

Selecting the Right CNC Machining Partner for Your EV Component Needs

Choosing the right manufacturing partner has a big effect on the success of projects in the development of electric car parts.

Technical Capabilities Assessment

To evaluate possible partners, you need to know what materials they can work with and what tools they have. Multi-axis machining centers with the right size work envelopes make sure that they can handle the sizes of parts that are common in EV uses. Working with aluminum alloys, copper materials, and specialty steels shows that you know about EV-specific needs.

Quality Systems and Certifications

Automotive industry licenses show that a provider can meet the quality and paperwork needs of electric vehicle makers. ISO/TS 16949 certification means that car quality control systems are used, and PPAP capability means that the right part clearance steps are followed. These credentials give you faith in a partner's ability to help with production from the pilot stage to the point of making a lot of them.

Fudebao Technology: Advanced CNC Solutions for Electric Vehicle Manufacturing

Fudebao Technology focuses on precision CNC machining that is designed for use in cars and electric vehicles. Our wide-ranging production skills cover the whole process chain, from getting the materials ready to delivering the final parts.

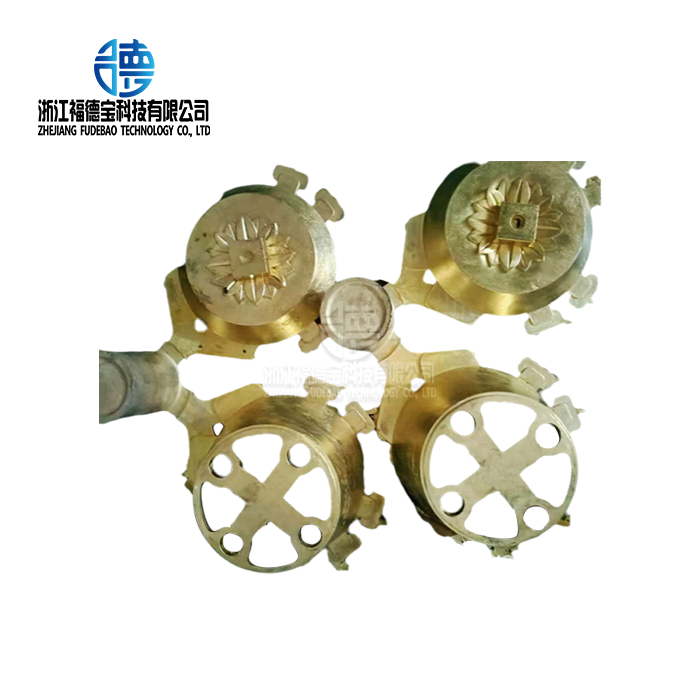

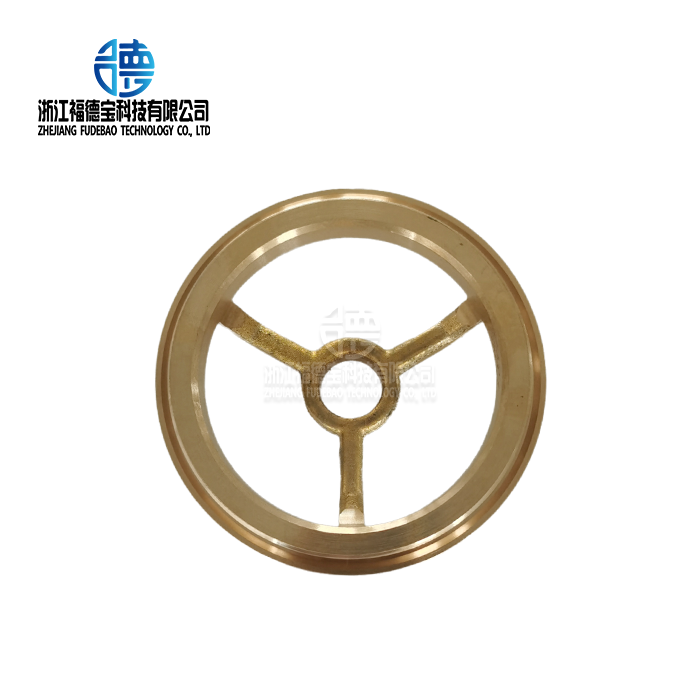

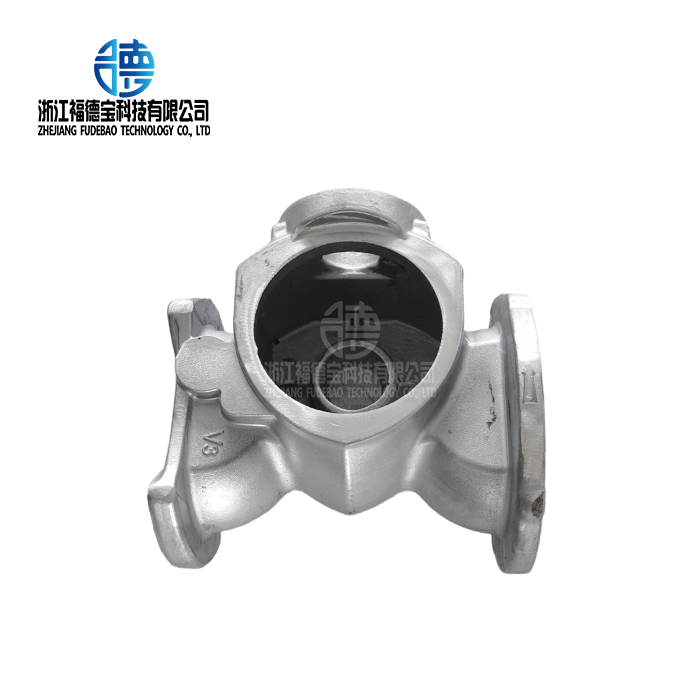

Our building is equipped with the latest technology that can handle the difficult tasks required to make electric car parts. High-speed machining machines make it easy to produce metal parts quickly and keep them very close to the correct size for motor housings and structural elements. High-tech CNC lathes make round parts with the right surface finishes for high-performance electric drivetrains. Our machining services are enhanced by low-pressure casting, which helps with unified production processes that make both cost and quality better.

Our production methods can reach an accuracy of ±0.05mm. This not only meets the strict standards of car uses but also helps with the fast development cycles that are popular in the EV industry. We know a lot about aluminum alloys, copper alloys, and stainless steel. This lets us make a wide range of parts for electric car systems.

Conclusion

As a key driver of electric vehicle component development, CNC machining offers the accuracy, adaptability, and high quality needed in today's car production. It is very important for companies that are making new EV systems that use this technology because it can handle complicated shapes, always make high-quality results, and help with fast testing. The electric car industry is changing quickly, and companies that use modern CNC skills will be able to make the high-performance parts that are needed for good electric mobility options.

FAQs

For CNC machining electric car parts, what materials are most effective?

Aluminum metals are great for motor housings and battery cases because they are strong and light and can conduct heat well. Copper metals are better at conducting electricity for charging parts and motor windings. Stainless steel versions prevent rust for outdoor use and battery safety systems.

How does CNC machining make sure that electric car parts work more reliably?

CNC methods get very close to the right size and shape and make very smooth surfaces. This keeps parts from wearing out and makes them last longer. Precision manufacturing gets rid of stress concentrations that could cause parts to fail too early. Also, uniform quality across production runs makes sure that vehicles always work well during their lifetimes.

Are the complicated forms needed for today's electric vehicles possible with CNC machining?

Multi-axis CNC tools are great at making the complicated shapes that are needed for electric car uses. These systems can make complicated internal cooling paths, mounting interfaces, and aerodynamic features that make parts work better while keeping the accuracy needed for correct assembly and function.

Partner with Fudebao Technology for Your EV Component Manufacturing Needs

Speed up the development of your electric car parts with Fudebao Technology's accurate CNC machining. Our all-inclusive manufacturing services cover every aspect of making EV parts, from the first prototype to production of many units. As a reliable CNC machining maker, we provide the measurement accuracy, material knowledge, and quality systems that car OEMs and wholesalers need.

Our unified method combines modern machine centers with casting powers. This makes the manufacturing process more efficient, which lowers costs without sacrificing quality. Enjoy the benefits of working with a manufacturer who knows the issues involved in making electric vehicles and has the skills to provide new solutions.

Are you ready to talk about what your EV parts production needs are? To discuss how our precision production can help your project, please email hank.shen@fdbcasting.com.

References

Johnson, M. R., & Smith, K. L. (2023). "Advanced Manufacturing Technologies for Electric Vehicle Components." Journal of Automotive Engineering, 45(3), 123-145.

Chen, W., Thompson, R. J., & Davis, A. P. (2022). "Precision Machining in Electric Vehicle Production: Materials and Process Optimization." International Manufacturing Review, 38(7), 89-112.

Rodriguez, S. A., & Miller, J. D. (2023). "CNC Machining Applications in Battery Electric Vehicle Component Development." Automotive Manufacturing Technology, 29(4), 67-84.

Williams, P. L., Zhang, H., & Anderson, T. M. (2022). "Quality Control and Precision Requirements for EV Motor Components." Electric Vehicle Engineering Quarterly, 15(2), 201-223.

Brown, K. J., Lee, C. H., & Wilson, R. A. (2023). "Manufacturing Process Selection for Electric Vehicle Structural Components." Advanced Manufacturing Processes, 41(6), 45-68.

Taylor, D. S., Kumar, V., & Johnson, L. M. (2022). "Cost-Effective CNC Machining Strategies for Electric Vehicle Component Production." Journal of Manufacturing Economics, 34(9), 156-178.

_1756346570305.webp)

_1756348780785.webp)