A cutting-edge method of producing thin-wall components, low pressure casting offers unmatched structural integrity and accuracy. Through the use of mild pressure to fill molds, this controlled casting method ensures full cavity filling while removing turbulence. The low pressure casting process offers better surface polish, less porosity, and remarkable dimensional precision in contrast to conventional gravity casting techniques. This technique is being used more and more by engineering teams in the automotive, aerospace, and industrial sectors to create complicated geometries, lightweight housings, and brackets. When wall thicknesses fall below 3 mm, the technology performs very well, while traditional techniques find it difficult to maintain uniformity and quality requirements.

Understanding the Fundamentals of Low Pressure Casting Technology

Molten metal is guided into mold cavities by precisely regulated pressure differentials in the low pressure casting process. A riser tube allows metal to enter from below, resulting in laminar flow patterns that reduce oxide production and air entrapment. The usual pressure range is between 0.2 and 1.0 bar, which is enough to defy gravity and avoid turbulent filling.

For thin-wall applications, where conventional high-pressure techniques may result in mold damage or insufficient fills, this gentle approach is crucial. Throughout the casting cycle, accurate temperature control is made possible by the controlled environment. For certain component geometries, operators may improve outcomes by modifying cooling sequences, pressure cur

Low pressure casting advantages become particularly evident in aluminum applications. The procedure produces better mechanical qualities while preserving the integrity of the metal's chemistry. The fine and consistent grain structure helps to improve the strength-to-weight ratios that are crucial for parts used in automobiles and airplanes.

Critical Design Considerations for Thin-Wall Components

Careful consideration of design factors that affect metal flow and solidification is necessary for successful thin-wall casting. Variations in wall thickness must be kept to a minimum in order to avoid differential cooling rates that lead to stress concentrations. To guarantee consistent solidification, engineers should keep the thickness ratios between neighboring parts below 2:1.

Draft angles are important for surface quality and component ejection. Generally speaking, minimum draft requirements vary from 1° to 3° based on component height and wall thickness. Because abrupt changes might obstruct metal flow and provide possible failure spots, corner radii should be given particular attention.

Low pressure casting design considerations extend beyond geometry to include gating strategy. Feed systems need to minimize turbulence while delivering enough metal. Complex components may need more than one gate to guarantee full filling and appropriate directional solidification.

Cooling channel placement within the mold directly impacts cycle time and component quality. Strategic cooling system design prevents hot spots while maintaining controlled solidification progression. This becomes especially critical for thin sections prone to rapid heat loss.

Material Selection and Alloy Optimization

Alloy selection significantly influences casting success in thin-wall applications. Aluminum alloys like A356 and A357 offer excellent fluidity characteristics combined with good mechanical properties. TAfter solidification, these compositions retain structural integrity while flowing easily through narrow areas.

Silicon content must be carefully considered while casting aluminum at low pressure as it influences the material's fluidity and shrinkage properties. Although castability is improved by higher silicon levels, machinability in later processes may be compromised. Magnesium additions enhance strength but can increase oxidation tendencies during processing.

For thin-wall components, where fast cooling may result in undesirable microstructures, grain refining becomes crucial. Additions of titanium and boron encourage the production of fine, equiaxed grains, which enhances surface finish quality and mechanical characteristics.

Heat treatment response varies with alloy chemistry and section thickness. Thin walls may exhibit different aging characteristics compared to heavier sections within the same component. Understanding these variations allows optimization of thermal processing parameters.

Process Parameters and Quality Control

Low pressure casting parameters require precise calibration to achieve consistent results. Filling pressure must balance complete cavity penetration against potential mold damage or flash formation. Pressure application curves should follow predetermined profiles that optimize metal delivery rates.

Mold and metal thermal management are both included in temperature control. To provide sufficient fluidity without causing undue superheating, pouring temperatures usually range between 50 and 100°C above liquidus. Mold preheating prevents premature solidification while avoiding thermal shock to tooling.

Low pressure casting quality control relies on real-time monitoring of critical variables. Pressure sensors track application curves while temperature probes monitor thermal conditions. Statistical process control helps identify trends before they impact component quality.

Inspection procedures need to take into account the particular difficulties presented by thin-wall components. While radiographic testing indicates interior porosity, visual evaluation identifies surface abnormalities. Geometric conformance with technical requirements is verified by dimensional verification.

Automation and Industry 4.0 Integration

Advanced automation solutions are included into contemporary low pressure casting machine setups to improve repeatability and lessen human reliance. Temperature profiles, cycle timing, and pressure application sequences are all precisely managed by programmable logic controllers, which are not achievable with manual operation.

Low pressure casting automation extends beyond basic parameter control to include adaptive process optimization.In order to forecast the ideal parameters for future component designs, machine learning algorithms examine past data. Systems for real-time feedback automatically modify settings to meet quality standards.

Complete traceability throughout the production process is made possible by integration with factory execution systems. All process variables are captured in digital documentation, producing thorough records that support quality audits and PPAP documentation standards.

Predictive maintenance features keep an eye on the state of the equipment to avoid unplanned downtime. Sensor networks monitor trends in temperature, pressure, and vibration to spot any problems before they affect output.

Troubleshooting Common Challenges

In thin-wall applications, low pressure casting flaws are often caused by insufficient filling or early solidification. Low metal temperature, restricted gating, or inadequate pressure are the usual causes of incomplete fills. Systematic evaluation of these variables helps identify root causes.

The state of the mold, the cleanliness of the metal, or the use of release agents may all cause problems with surface finish. The accumulation of residues that degrade surface quality is avoided with regular mold care. The dissolved gases that cause surface porosity are eliminated by proper degassing.

Dimensional variations often trace to thermal management issues or mold wear. Consistent preheating procedures ensure uniform thermal conditions. Regular mold inspection identifies wear patterns that require correction.

Cost Analysis and Economic Considerations

Low pressure casting cost analysis reveals significant advantages over alternative manufacturing methods for thin-wall components.Less machining is needed, which improves material utilization rates and lowers total manufacturing costs. The yield of the procedure is usually 85–90%, as opposed to 60–70% for traditional approaches.

Tooling costs may exceed those for gravity casting but remain substantially below die casting requirements. Mold life often surpasses 50,000 cycles with proper maintenance, distributing tooling investment across large production volumes.

Energy consumption per component typically runs lower than high-pressure alternatives due to reduced cycle pressures and simplified equipment requirements. Maintenance costs remain moderate due to gentler operating conditions that minimize wear.

Reductions in warranty claims and scrap rates are closely correlated with quality improvements. Improved mechanical qualities prolong component service life, while increased dimensional uniformity lowers the need for downstream machining.

Conclusion

Low pressure casting for thin-wall components requires close consideration of process control, material selection, and design optimization. Understanding the special qualities of this delicate shaping process and using its built-in benefits are essential for success. Consistent outcomes that satisfy exacting industrial standards are guaranteed by appropriate equipment selection, parameter optimization, and quality control procedures. Through automated integration and sophisticated monitoring systems that improve capability and dependability, the technology keeps developing. Businesses who make investments in low pressure casting skills put themselves in a position to satisfy the increasing need for high-performance, lightweight components in the industrial, automotive, and aerospace sectors.

Partner with Fudebao Technology for Advanced Low Pressure Casting Solutions

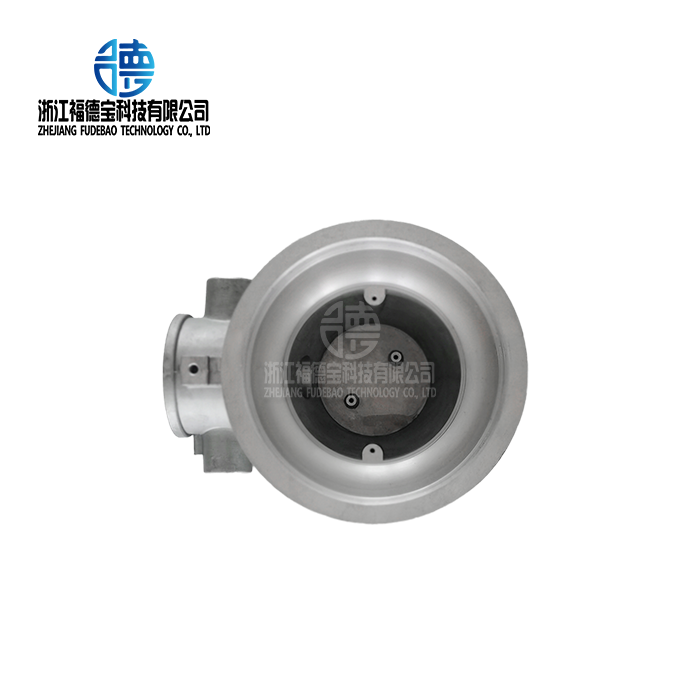

Fudebao Technology stands ready to transform your thin-wall component manufacturing through expert low pressure casting implementation. Modern low pressure casting machines and precise CNC equipment are housed in our expansive facility, allowing for full processing from molten metal to completed components. We uphold stringent quality standards that attain ±0.05mm accuracy, satisfying the demanding specifications of industrial and automotive precision parts.

Our technical team has decades of expertise in quality control, process optimization, and alloy selection in a variety of sectors. We provide complete PPAP documentation support while maintaining full traceability throughout production. Whether you need prototype development or high-volume manufacturing, our low pressure casting supplier capabilities scale to meet your requirements.

Ready to explore how our advanced casting solutions can enhance your thin-wall component production? Contact us at hank.shen@fdbcasting.com to discuss your specific application requirements and discover the Fudebao Technology advantage.

References

1. Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

2. Flemings, M.C. "Solidification Processing in Light Alloy Casting Technology." Materials Science and Engineering Review, Vol. 65, 2019.

3. ASM International Handbook Committee. "ASM Handbook Volume 15: Casting Processes and Technologies." ASM International, 2018.

4. Bonollo, F. "Guidelines for Low Pressure Die Casting Process Optimization in Aluminum Alloys." Journal of Materials Processing Technology, Vol. 287, 2020.

5. European Committee for Standardization. "Aluminum and Aluminum Alloys - Castings - Chemical Composition and Mechanical Properties." EN 1706:2020.

6. Zhang, L. "Advanced Process Control in Low Pressure Casting: Theory and Industrial Applications." International Journal of Advanced Manufacturing Technology, Vol. 108, 2020.

_1756345939856.webp)

_1756346144394.webp)

_1756346570305.webp)

_1756352625880.webp)

_1756360265131.webp)