Through carefully regulated cycles of heating and cooling, heat treatment changes the mechanical characteristics of copper casting components. This extensive procedure improves the strength, flexibility, and resistance to corrosion of copper alloy components used in electrical equipment, automotive, industrial machinery, and aerospace applications. Comprehending appropriate heat treatment methods guarantees the best possible performance and lifespan of your copper casting components while adhering to strict industry requirements for material integrity and dimensional correctness.

Understanding Copper Casting Heat Treatment Fundamentals

One crucial metallurgical procedure that changes the microstructure of copper castings without changing their chemical makeup is heat treatment. To obtain the required mechanical qualities, the process requires exact timing, temperature control, and cooling rates. Depending on their composition, copper casting alloys react to heat treatment differently; bronze, brass, and pure copper all need various methods.

Atomic diffusion inside the metal matrix is the basis for the basic idea. Atoms become more mobile at certain temperatures, which relieves tension and refines grain structure. To produce parts that satisfy industrial durability standards and automobile accuracy requirements, copper casting producers must comprehend these metallurgical concepts.

Consistent outcomes are ensured by maintaining a constant temperature during the copper casting process. In order to avoid localized overheating or inadequate treatment, advanced furnace technology maintains exact temperature profiles. These crucial factors are monitored and controlled by computerized systems in modern facilities, providing reproducible results for large production runs.

Essential Heat Treatment Methods for Copper Alloys

Annealing stands as the most common heat treatment for copper casting components. Parts are heated to 300–650°C, depending on the alloy composition, and then carefully cooled. Annealing increases ductility and machinability while reducing internal tensions during the cooling process of the copper casting mold.

Solution heat treatment dissolves secondary phases back into the copper matrix at elevated temperatures. Copper casting alloys containing aluminum, nickel, or beryllium benefit significantly from this process. The treatment homogenizes the microstructure, preparing components for subsequent aging treatments that enhance strength properties.

Precipitation hardening, or age hardening, strengthens copper castings through controlled precipitation of fine particles within the matrix. This two-stage process begins with solution treatment followed by aging at lower temperatures. TIncreased yield strength and sufficient ductility for demanding applications are features of the resultant copper casting quality.

Without substantially changing the mechanical characteristics, stress relief eliminates remaining tensions from copper casting. The low temperature treatment (150–300°C) is crucial for precision parts that need to maintain their dimensions while being machined or serviced. Stress-relieved copper castings are very useful in automotive and aeronautical applications.

Temperature Control and Cooling Strategies

Precise copper casting temperature management determines treatment effectiveness and final properties. Complex geometries are heated uniformly thanks to thermocouple placement across furnace chambers. In order to maintain ideal conditions, sophisticated monitoring systems automatically regulate heating elements and measure temperature differences.

The ultimate microstructures and characteristics are greatly influenced by cooling rates. Slow furnace cooling has different outcomes than rapid quenching in water or oil. Section thickness is a factor in copper casting design that influences cooling uniformity and possible deformation during treatment cycles.

During the heat treatment of copper casting, oxidation is prevented using controlled environment furnaces. Environments including nitrogen, hydrogen, or vacuum preserve surface quality while allowing for exact temperature control. This method improves the overall results of copper casting metallurgy by removing scale development and lowering the need for further finishing.

Every copper casting application requires a precise calibration of time-temperature relationships. Electrical connections that prioritize conductivity need a different treatment schedule than automotive components that require specified hardness levels. Process documentation meets client requirements and guarantees consistency across manufacturing batches.

Quality Control and Testing Protocols

Mechanical property verification confirms heat treatment effectiveness through standardized testing procedures. Measurements of elongation, yield strength, and tensile strength confirm the strength properties of copper casting. Sample coupons processed alongside production parts ensure representative results and maintain quality consistency.

Hardness testing provides rapid assessment of heat treatment success across copper casting surfaces. Depending on the shape of the component and the thickness of the material, the Rockwell, Brinell, and Vickers techniques each have benefits. High-volume quality control is made possible by automated hardness testers that preserve measurement accuracy and consistency.

Grain structure, phase distribution, and possible copper casting flaws are revealed by microstructural study using metallographic analysis. Before they have an impact on component performance, treatment abnormalities are detected by optical and electron microscopy. For continuous improvement projects, this analysis directs process optimization and troubleshooting activities.

Dimensional stability verification ensures heat treatment processes maintain copper casting design tolerances. Critical dimensions are measured by coordinated measuring devices both before and after treatment, detecting any patterns of distortion. By monitoring dimensional fluctuations, statistical process control makes it possible to proactively modify treatment settings as needed.

Industry-Specific Applications and Requirements

Excellent dimensional precision and long-term dependability in a range of temperature conditions are required for automotive copper castings. Thermal cycling must be tolerated by heat treatment procedures for cooling system components, electrical housings, and engine parts while preserving structural integrity. Comprehensive PPAP paperwork proving process control and capacity is required of automotive suppliers.

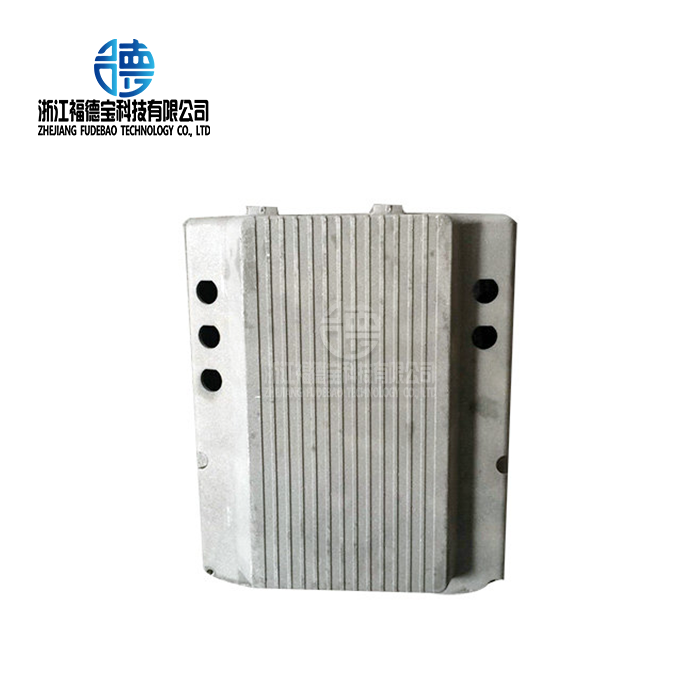

Copper casting methods that improve heat conductivity and wear resistance are given priority in industrial equipment applications. Heat-dissipating treatments that preserve mechanical strength are beneficial for motor housings, pump parts, and heat exchangers. Adaptable batch production capabilities support a range of industrial applications with different component sizes and treatment needs.

Heat treatments that maintain conductivity while enhancing corrosion resistance are necessary for components used in the electrical and energy sectors. Electrical connections, renewable energy components, and power equipment housings need specific treatment regimens that strike a compromise between mechanical and electrical performance. Procedures for treatment parameter selection and validation are guided by adherence to industry standards.

The highest standards of process control and documentation for copper casting equipment are required for aerospace applications. Procedures for heat treatment must be traceable, repeatable, and compliant with strict quality standards. While preserving the lightweight, high-strength qualities necessary for aircraft performance standards, advanced inspection procedures confirm the efficacy of the treatment.

Process Optimization and Troubleshooting

Furnace calibration ensures accurate temperature control throughout copper casting automation systems. Regular calibration schedules maintain measurement accuracy while preventing treatment variations that could affect component properties. Temperature uniformity is identified and maintenance scheduling is guided for maximum performance by multi-point calibration throughout furnace operating zones.

Treatment schedule development requires careful consideration of alloy composition, component geometry, and desired properties. Copper casting patterns influence heating and cooling rates, necessitating customized treatment parameters for complex shapes. Design of experiments methodologies optimize treatment schedules while minimizing development time and material consumption.

Excessive grain growth, insufficient solution treatment, and processing distortion are typical problems with copper casting. While directing remedial measures, root cause analysis pinpoints the process factors causing these issues. Preventive actions deal with possible problems before they affect delivery dates or manufacturing quality.

Initiatives for continuous improvement use manufacturing data to gradually enhance heat treatment procedures. While maintaining steady rates of material consumption and recycling for copper casting, statistical analysis finds patterns and optimization potential. Continuous improvements to process efficiency and quality results are fueled by cooperation between production staff and metallurgical teams.

Advanced Technologies and Future Developments

Induction heating technology offers precise, localized heat treatment for copper casting finishing applications. Selective heating of specific component areas enables property gradients while reducing overall energy consumption. This approach proves particularly valuable for large components requiring different properties in various sections.

Development time and material costs are decreased by using computer modeling to forecast heat treatment results before to physical processing. Complex copper casting applications' temperature distributions and cooling patterns are simulated using finite element analysis.These tools guide process parameter selection while identifying potential issues before production implementation.

Real-time monitoring systems use wireless communication networks and embedded sensors to track the effectiveness of therapy. IoT-enabled furnaces provide ongoing input on cooling rates, atmospheric composition, and temperature uniformity. Predictive maintenance scheduling for equipment dependability is made possible by data analytics, which also finds optimization possibilities.

The possibilities for heat-treated copper castings in demanding applications are increased by newly developed alloy compositions. By combining creative treatment techniques with optimal chemical compositions, advanced copper-based materials provide improved performance. New treatment methods that provide more performance possibilities for next-generation applications are still being developed via research.

Conclusion

The performance and dependability of copper casting components in a variety of industrial applications are greatly improved by heat treatment procedures. Making educated selections about the best treatment plans for particular needs requires an understanding of the principles of annealing, solution treatment, precipitation hardening, and stress relief.

Temperature control, cooling rates, and quality testing processes must all be carefully considered for successful deployment. While cutting-edge technologies continue to increase treatment capabilities and efficiency, process selection is guided by industry-specific needs. In order to achieve excellent component performance and dependability, working with seasoned copper casting professionals guarantees access to established knowledge and cutting-edge technology.

Partner with Fudebao Technology for Expert Copper Casting Solutions

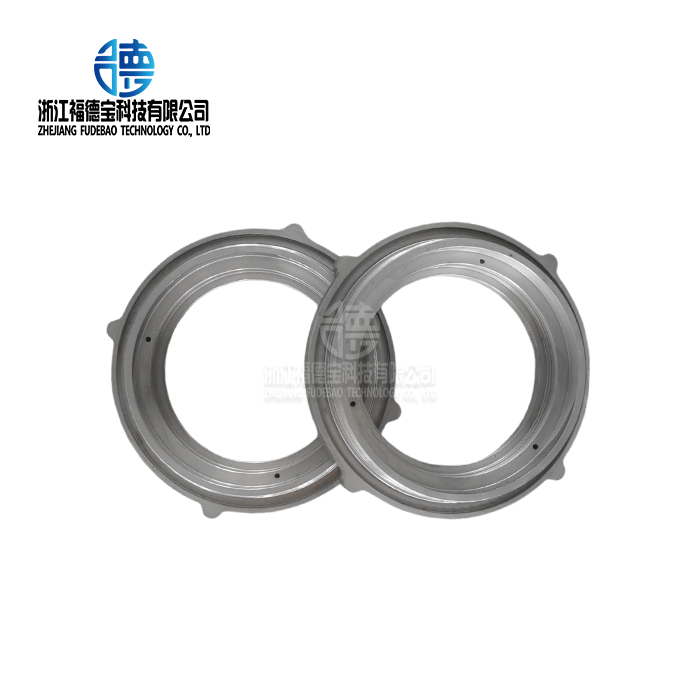

For use in automotive, industrial, electrical, and aerospace industries, Zhejiang Fudebao Technology Co., Ltd. provides precisely manufactured copper casting components with cutting-edge heat treatment capabilities. Our cutting-edge facilities use CNC lathes, high-speed machining centers, and specialist heat treatment equipment to guarantee dimensional precision within tolerances of ±0.05mm.

From melting to finishing and surface treatment, our all-inclusive copper casting process takes care of the whole production cycle. Strict quality control is maintained throughout manufacturing, and skilled metallurgy teams optimize heat treatment regimens for every application. As a reputable supplier of copper casting, we provide one-stop delivery services that optimize your supply chain and guarantee dependable delivery performance and constant quality.

Our adaptable capabilities support a variety of project needs while keeping low cost, whether you want high-volume production runs or prototype development. Your engineering team and technical support teams work together to optimize designs for performance and manufacturability. Are you prepared to use professional heat treatment services to improve your components? Get in touch with us at hank.shen@fdbcasting.com to talk about your unique copper casting needs and find out how our cutting-edge skills may help your next project.

References

1. Davis, J.R. (2001). Copper and Copper Alloys: Heat Treatment and Properties. ASM International Handbook Committee, Materials Park, Ohio.

2. Smithells, C.J. & Brandes, E.A. (1998). Metals Reference Book: Heat Treatment of Non-Ferrous Casting Alloys. Butterworth-Heinemann, Oxford.

3. American Society for Testing and Materials (2019). Standard Practice for Heat Treatment of Copper and Copper-Base Alloy Castings. ASTM B917-19, West Conshohocken, PA.

4. Porter, D.A. & Easterling, K.E. (2004). Phase Transformations in Copper-Based Casting Alloys: Principles and Applications. Chapman & Hall, London.

5. Copper Development Association (2020). Heat Treatment Guidelines for Copper Casting Applications in Manufacturing Industries. Technical Publication 145, New York.

6. International Copper Association (2018). Metallurgical Principles of Heat Treatment in Copper Alloy Casting Processes. Research Report ICA-2018-MT, Brussels.

_1756346613780.webp)

_1756348300182.webp)

_1756349071334.webp)

_1756349862928.webp)