Cost effectiveness and precise capabilities become important considerations when choosing between die casting and investment casting for your production requirements. Die casting provides outstanding dimensional precision for aluminum components at reduced prices per unit and excels in high-volume manufacturing with quick cycle times. Although technique involves a larger initial investment and longer production cycles, investment casting offers complicated geometries and greater surface polish. The decision is based on the precise tolerances required for your application, the material specifications, and your particular volume needs.

Understanding Manufacturing Process Fundamentals

Numerous processes are used in modern metal casting, each one tailored to a particular purpose and set of manufacturing specifications. By injecting molten metal into steel molds under tremendous pressure, die casting produces remarkably consistent results across thousands of cycles.

In the pressure die casting process, molten aluminum or zinc alloys are forced into finely machined cavities at pressures between 1,500 and 25,400 PSI. This method of high pressure casting removes porosity in crucial places and guarantees full mold filling.

Investment casting, on the other hand, uses ceramic shells around wax patterns to create complicated exterior features and intricate interior passageways. By heating the wax, this casting method creates hollow ceramic molds that may be filled with molten metal.

Three core process differences distinguish these methods:

- Pressure application: Die casting uses mechanical force while investment casting relies on gravity

- Mold materials: Steel tooling versus ceramic shells

- Pattern creation: Permanent molds versus disposable wax patterns

Pressure die casting offers the best efficiency and cost-effectiveness for producing vehicle housings or electrical components quickly.

Precision Capabilities and Dimensional Accuracy

When choosing a casting technique, dimensional control is crucial, especially for applications in the automotive and aerospace industries that need precise tolerances.Casting tolerance achievement depends on process control, tooling quality, and material properties.

For the majority of dimensions, aluminum die casting routinely achieves tolerances of ±0.05mm to ±0.13mm; in some specialized applications, sophisticated die casting machine control systems allow for tolerances of ±0.025mm. Rigid steel tools and consistent high-pressure injection are the sources of this accuracy.

Investment casting delivers tolerances of ±0.08mm to ±0.25mm, varying based on part size and geometry complexity. The ceramic shell expansion and contraction during processing introduces some dimensional variation compared to steel tooling.

Surface finish comparison shows distinct characteristics:

- Die casting: 1.6-6.3 µm Ra typical surface roughness

- Investment casting: 0.8-3.2 µm Ra achievable surface quality

- Secondary machining: Both processes support precision finishing operations

Wall thickness capabilities differ substantially between methods. Die casting maintains consistent 2-6mm wall sections effectively, while investment casting handles varying thickness from 1-50mm within single components.

Complex internal cooling channels and undercuts present challenges for traditional die casting but investment casting accommodates intricate internal geometries naturally through wax pattern flexibility.

If you need consistent dimensional accuracy across high production volumes, then die casting offers superior repeatability and statistical process control capabilities.

Material Selection and Alloy Compatibility

The performance of the finished component and the feasibility of the casting process are greatly impacted by the choice of alloy. Aluminum, zinc, and magnesium compositions that are suited for high-pressure injection and quick solidification are the main emphasis of die casting alloys.

A380, A383, and A360 are common aluminum die casting alloys with superior mechanical and fluidity qualities. For automotive applications, these die casting alloys have tensile strengths of 310–330 MPa together with strong corrosion resistance.

Zinc die casting produces outstanding surface quality features and greater dimensional stability by using alloys such as ZA-8 and ZA-12. Under ideal circumstances, zinc alloys may attain casting tolerances as close as ±0.025mm.

Investment casting accommodates broader alloy ranges including:

- 356, A357, and special compositions of aluminum alloys

- 316L, 17-4PH stainless steel to prevent corrosion

- Copper alloys: electrical uses for brass and bronze

- Superalloys for aeronautical applications: Inconel and Hastelloy

Heat treatment compatibility varies between processes. Die casting parts support T6 heat treatment for aluminum alloys, achieving tensile strengths exceeding 280 MPa. Investment castings accommodate various heat treatment cycles including solution annealing and precipitation hardening.

Material waste reduction favors die casting through efficient runner systems and automated trimming. Investment casting generates more waste through ceramic shells and longer runner systems required for proper filling.

If you need specialized alloy compositions or superior material properties, then investment casting provides greater flexibility in material selection and heat treatment options.

Production Volume and Lead Time Considerations

Production planning requires careful evaluation of volume requirements and delivery schedules. Casting cycle time directly impacts manufacturing capacity and customer satisfaction levels.

Die casting achieves remarkable cycle efficiency with typical times of 30-300 seconds per part depending on size and complexity. Automated die casting machines operate continuously with minimal operator intervention, maximizing throughput potential.

Investment casting requires 5-10 days minimum lead time for shell preparation and processing. Each production batch involves pattern preparation, shell building, dewaxing, and controlled cooling phases that cannot be accelerated significantly.

Production capacity comparison reveals distinct scaling characteristics:

- Die casting: 200-2,000+ parts per machine per day

- Investment casting: 10-100 parts per batch cycle

- Automation potential: Die casting supports full automation integration

Mold design flexibility affects production adaptability. Die casting molds accommodate design changes through insert modifications but major geometry changes require new tooling investment.

Investment casting patterns enable rapid design iteration and prototyping without significant tooling investment. This flexibility supports product development and low-volume specialized applications effectively.

Quality control integration differs between processes. Die casting supports in-line inspection and automated sorting systems. Investment casting relies more heavily on batch sampling and manual inspection protocols.

If you need rapid delivery of high-volume production orders, then die casting provides unmatched speed and consistency for meeting aggressive delivery schedules.

Industry Applications and Use Case Optimization

Operating circumstances and particular performance criteria determine an application's appropriateness. Die casting is highly preferred in automotive applications for structural elements that need high strength-to-weight ratios, such as engine blocks and gearbox housings.

Die casting offers superior dimensional control for electrical enclosures, heat dissipation elements, and motor housings, which are components used in the electrical sector. The process ensures consistent wall thickness critical for thermal management and electromagnetic shielding.

Aerospace applications present unique challenges requiring careful process selection. Die casting serves aircraft interior components and non-critical structural elements effectively. Investment casting handles complex turbine components and safety-critical parts requiring extensive traceability.

Industrial machinery applications span both processes:

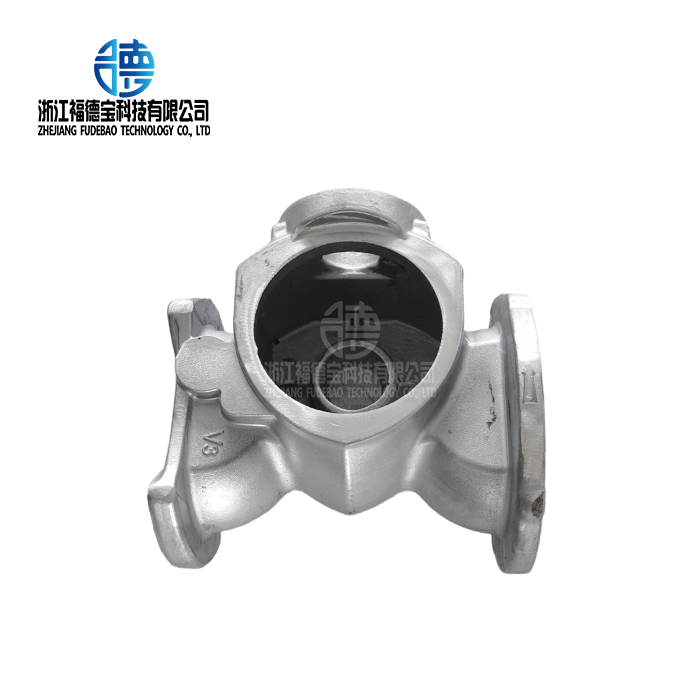

- Die casting: Pump housings, gearbox components, and mounting brackets

- Investment casting: Valve bodies, impellers, and complex hydraulic components

- Hybrid approaches: Some assemblies combine both casting methods strategically

Medical device manufacturing increasingly utilizes investment casting for implant components and surgical instruments requiring biocompatible materials and complex geometries. Die casting supports diagnostic equipment housings and non-implant medical devices.

Surface treatment compatibility affects final component performance.Both procedures facilitate machining, powder coating, and anodizing. For crucial aesthetic applications, die casting surfaces sometimes need further treatment.

Die casting offers proven dependability and cost-effectiveness for severe operating situations if you require components for high-stress industrial or automotive applications.

Fudebao Technology Advantages in Die Casting Excellence

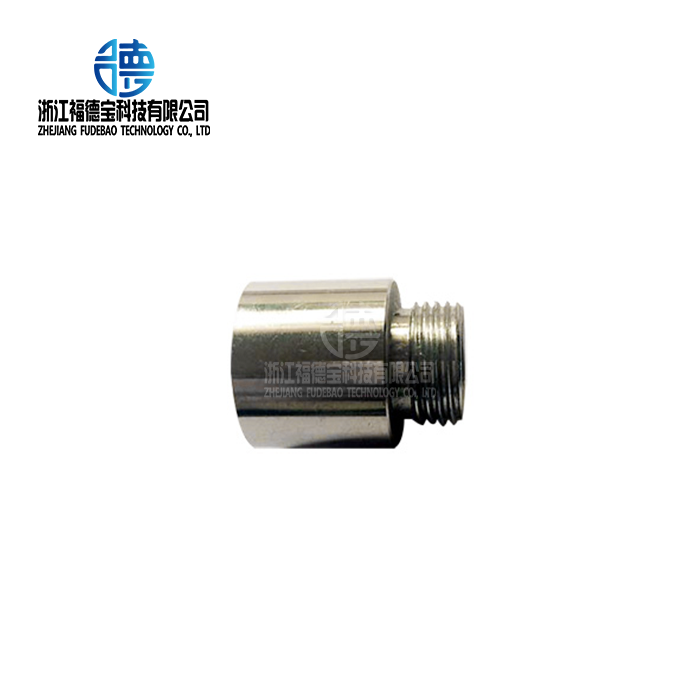

- Advanced Equipment Integration: Our facility features high-speed machining centers and precision die casting machines, ensuring casting cycle time optimization and consistent quality output across all production runs.

- Comprehensive Process Control: Complete "melting-casting-finishing-surface treatment" capabilities under one roof eliminate quality variations and reduce lead times for complex component requirements.

- Precision Achievement: By using sophisticated die casting machine control systems and precise mold design, dimensional accuracy up to ±0.05mm is achieved, continuously satisfying automotive and aerospace criteria.

- Material expertise: In-depth understanding of the casting processes for copper, aluminum, and stainless steel alloys, with the ability to optimize alloy choices for particular application needs and performance standards.

- Global Supply Experience: Direct supplier relationships with international brands including American HAAS automation and ESS energy storage systems, demonstrating proven capability in demanding applications.

- Quality Documentation: Full PPAP documentation support and traceability systems meeting automotive OEM requirements and aerospace certification standards for critical component applications.

- Production Flexibility: From prototype to high-volume production, both low-pressure casting and high-pressure die casting can effectively handle a range of volume needs.

- Technical Support: From mold design to production optimization, engineering cooperation ensures the best casting process choice and component performance.

- Integrated Manufacturing: CNC machining and finishing operations eliminate secondary supplier coordination while maintaining dimensional control throughout the complete manufacturing process.

- Industry Recognition: Benchmark enterprise status in Chinese aluminum foundry sector through consistent quality delivery and innovative manufacturing process development initiatives.

Making the Right Choice for Your Manufacturing Requirements

Selecting between die casting and investment casting requires comprehensive evaluation of multiple factors including volume projections, precision requirements, and total cost of ownership. Each process offers distinct advantages suited to specific application requirements.

Die casting excels in high-volume applications requiring rapid production, consistent dimensional accuracy, and cost-effective manufacturing. The process supports automotive, electrical, and industrial applications where repeatability and efficiency drive success.

Investment casting provides superior flexibility for complex geometries, specialized alloys, and low-volume production requirements. Applications demanding intricate internal features or exotic materials benefit from this process capability.

Decision criteria should include:

- Annual volume requirements and growth projections

- Dimensional tolerance and surface finish specifications

- Material requirements and performance criteria

- Budget constraints and total cost analysis

- Production timeline and delivery requirements

Hybrid manufacturing approaches sometimes optimize component design by utilizing both processes strategically within single assemblies. This approach leverages each process's strengths while minimizing individual limitations.

If you need reliable, high-volume production with excellent dimensional control, then die casting provides the optimal combination of quality, efficiency, and cost-effectiveness for most industrial applications.

Conclusion

The choice between die casting and investment casting ultimately depends on your specific production requirements, volume needs, and quality expectations. Die casting offers superior economics for high-volume applications requiring excellent dimensional control and rapid production cycles. Investment casting provides greater design flexibility and material options for complex, lower-volume applications. Understanding these fundamental differences enables informed decision-making that optimizes both performance and cost-effectiveness. Partnering with experienced manufacturers like Fudebao Technology ensures access to proven expertise and advanced capabilities necessary for successful project execution and long-term manufacturing success.

Partner with Fudebao Technology for Superior Die Casting Solutions

Choosing the right die casting supplier ensures project success and long-term manufacturing partnership benefits. Fudebao Technology combines advanced equipment, proven expertise, and comprehensive capabilities to deliver exceptional results for demanding applications.

Our integrated manufacturing approach eliminates coordination challenges while maintaining strict quality control throughout the entire production process. From initial mold design through final surface treatment, every step receives expert attention and precision execution.

Global automotive and industrial clients trust our aluminum die casting capabilities for critical components requiring dimensional accuracy, material consistency, and reliable delivery performance. Our benchmark enterprise status reflects continuous commitment to manufacturing excellence and customer satisfaction.

Technical collaboration begins with your initial concept, utilizing our engineering expertise to optimize component design for manufacturing efficiency and performance optimization. This partnership approach ensures optimal results while minimizing development time and production costs.

Comprehensive quality documentation and certification support meets the most demanding industry standards including automotive PPAP requirements and aerospace traceability specifications. Our systems provide complete confidence in component reliability and performance consistency.

Whether your application requires precision automotive components, electrical enclosures, or industrial machinery parts, our die casting expertise delivers proven results. Contact us at hank.shen@fdbcasting.com to discuss your specific requirements and discover how our comprehensive capabilities can optimize your next project.

References

1. Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Techniques and Design." 2nd Edition, Butterworth-Heinemann, 2015.

2. Vinarcik, E.J. "High Integrity Die Casting Processes." John Wiley & Sons, 2003.

3. Brown, J.R. "Foseco Ferrous Foundryman's Handbook." 11th Edition, Butterworth-Heinemann, 2000.

4. Beeley, P.R. "Foundry Technology." 2nd Edition, Butterworth-Heinemann, 2001.

5. ASM International. "ASM Handbook Volume 15: Casting." ASM International, 2008.

6. Stefanescu, D.M. "Science and Engineering of Casting Solidification." 3rd Edition, Springer, 2015.

_1756345939856.webp)

_1756347888208.webp)

_1756346668222.webp)

_1756352400994.webp)