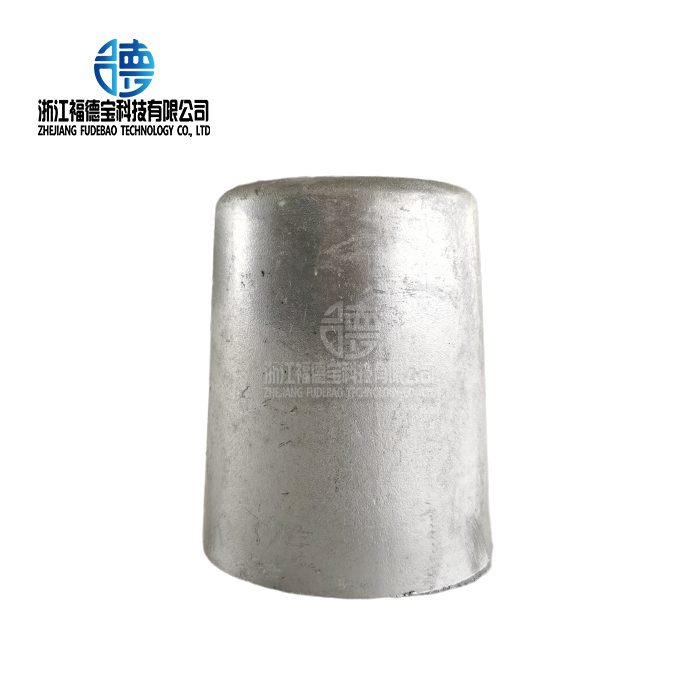

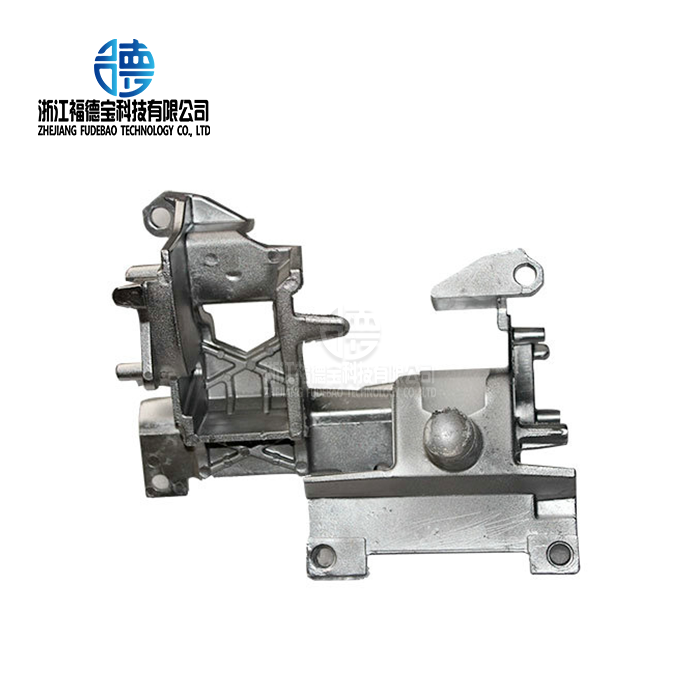

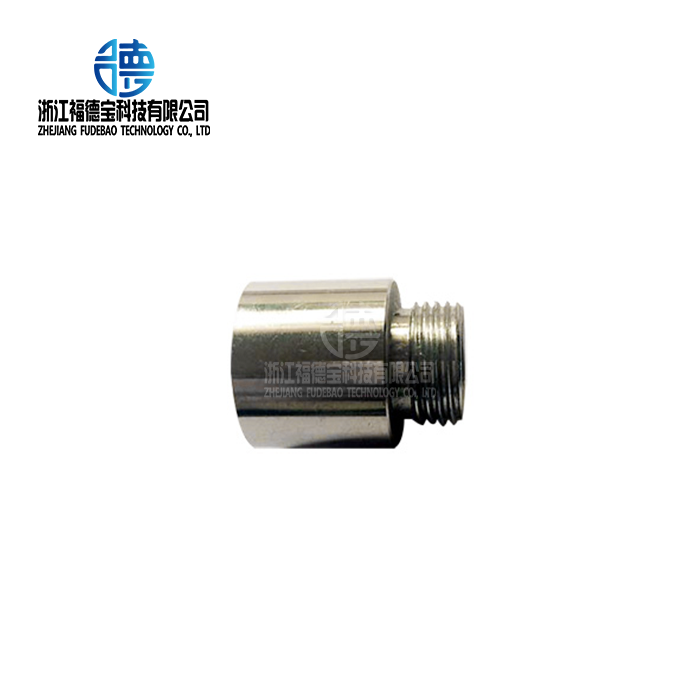

For bespoke copper casting projects, the finest OEM practices focus on thorough quality control systems, sophisticated mold creation, and exact material selection. Dimensional precision, temperature control, and a thorough grasp of alloy qualities are necessary for successful copper casting. OEMs get access to complete solutions covering the melting, casting, finishing, and surface treatment processes when they collaborate with seasoned manufacturers such as Fudebao Technology. Using automated equipment and tried-and-true foundry methods, our plant produces copper casting components with tolerances as high as ±0.05mm, supporting industrial applications, electrical housings, and automotive precision parts.

Understanding OEM/ODM Excellence in Copper Casting Manufacturing

Projects involving custom copper casting need specific expertise that goes beyond conventional production techniques. When creating copper alloy components for industrial equipment, heat exchangers, and electrical systems, Original Equipment Manufacturers and Original Design Manufacturers encounter particular difficulties. Precise temperature control, appropriate mold design, and a deep comprehension of material characteristics are necessary for the copper casting process.

In order to satisfy ever-more-complex requirements, contemporary copper casting processes have developed. Innovation in foundry operations is driven by standards for corrosion resistance, electrical conductivity, and thermal control. Copper casting solutions that provide both performance and cost-effectiveness in high-volume production settings are especially advantageous to automotive suppliers.

Reputable copper casting foundry enterprises combine many production skills under one roof. This strategy ensures constant quality throughout the manufacturing cycle while removing supplier coordination issues. To get better results, classical casting techniques are complemented by sophisticated CNC machining centers and automated finishing equipment.

Our OEM/ODM Strengths in Copper Casting Excellence

Fudebao Technology brings decades of copper casting expertise to OEM partnerships across automotive, industrial, and electrical sectors. From the first mold creation to the last surface treatment applications, our extensive production capabilities cover the whole copper casting process.

Modern machinery such as precise CNC lathes, high-speed machining centers, and specialist low-pressure casting machines are housed at our facilities.This integrated approach allows us to maintain tight control over copper casting quality while achieving remarkable efficiency in production cycles. Temperature monitoring systems ensure optimal melting conditions for various copper casting alloys.

Our capacity for research and development allows us to address intricate copper casting design problems. In order to optimize part shape, material selection, and cooling solutions, our technical team works in tandem with our customers. This collaborative strategy has been effective in lowering copper casting flaws and enhancing component performance in general.

Expertise in supply chain management guarantees consistent access to high-quality copper casting materials. Consistent alloy compositions and delivery dates are ensured by long-term partnerships with reliable suppliers. The needs of the automotive and aerospace industries are supported by quality certificates and traceability paperwork.

Comprehensive Customization Options for Copper Casting Projects

Physical design customization begins with thorough analysis of your copper casting applications.Component performance and manufacturing viability are directly impacted by parting line location, draft angles, and wall thickness optimization. Our design team predicts the behavior of copper casting during solidification using sophisticated modeling tools.

Functional feature integration allows incorporation of threaded inserts, mounting bosses, and complex internal passages. These design elements eliminate secondary operations while maintaining structural integrity. Copper casting techniques enable creation of intricate geometries that would be impossible through conventional machining alone.

Different copper casting alloys that are suited to certain performance criteria are included in the material selection process. High conductivity formulations are advantageous for electrical applications, whilst improved corrosion resistant qualities are necessary for maritime conditions. By carefully controlling the alloy composition, mechanical strength properties may be maximized.

Options for surface finishes include precision-machined surfaces and as-cast texturing. Applications of protective coatings, chemical treatments, and shot blasting improve both look and functionality.These finishing processes integrate seamlessly with our copper casting automation systems.

Branding and identification requirements receive careful attention throughout the copper casting design process.It is possible to directly integrate standard marks, component numbers, and raised or recessed logos into casting tooling. This method guarantees long-lasting identification that endures challenging operational circumstances.

Advanced Copper Casting Technology Integration

Modern copper casting equipment enables unprecedented precision in component manufacturing.Throughout the casting cycle, ideal temperature profiles are maintained by computer-controlled melting devices. Automated mold handling improves uniformity while lowering the danger of contamination.

Quality monitoring systems track critical parameters during each phase of the copper casting process. Real-time data collection identifies potential issues before they impact component quality. Statistical process control methods ensure long-term stability in production outcomes.

The ODM Advantage in Copper Casting Innovation

Partnerships with Original Design Manufacturing provide doors to innovative copper casting development. Our cooperative strategy blends our technological know-how with your understanding of the market to provide creative solutions. This collaboration often results in innovative designs that provide businesses a competitive edge.

Technical feasibility assessments and thorough market analyses are the first steps in co-development projects. Our engineering team assesses copper casting design proposals in relation to cost objectives and production limitations. Capabilities for rapid prototyping shorten development times while lowering costs.

Your copper casting inventions will stay safe throughout the development phase thanks to intellectual property protection. Sensitive design information is protected by confidentiality agreements and safe data handling procedures. Collaborative creative efforts may lead to joint patent potential.

Support for market entrance goes beyond the production of copper castings; it also includes help with supply chain optimization and regulatory compliance. Navigating international standards and certification requirements is made easier by our worldwide expertise. Time-to-market for innovative copper casting goods is accelerated by this all-inclusive service.

Our Proven Copper Casting Process Journey

Initial consultation sessions focus on understanding your specific copper casting requirements and performance objectives. Our technical staff examines current specs, designs, and quality requirements. Opportunities for improvement and possible obstacles are found in this thorough evaluation.

Flexible copper casting techniques are used in prototype development to allow for design revisions. While permanent mold choices facilitate higher-volume validation runs, sand casting processes provide affordable options for preliminary testing. Development cycles may be expedited with quick turnaround times.

Production planning entails a thorough examination of equipment allocation, quality control protocols, and copper casting mold needs. Our project management staff keeps lines of communication open with your company while coordinating every facet of the production process.

Dimensional inspection, material property testing, and functional performance verification are all part of quality validation. Modern metrology tools guarantee adherence to predetermined tolerances. Thorough documentation backs up efforts for continuous improvement and traceability needs.

Services for delivery and support are provided at every stage of the product's lifetime. Programs for inventory management guarantee consistent component availability, and technical assistance takes care of any issues with applications. Opportunities for continuous improvement and cost reduction are made possible by long-term cooperation agreements.

Exceptional Benefits of Partnering with Fudebao Technology

Cost optimization emerges naturally from our integrated copper casting approach. Reducing the number of supplier interfaces improves quality consistency and lowers administrative expense. Your bottom line will profit from economies of scale made possible by volume manufacturing capabilities.

Superior component performance is closely correlated with technical excellence in copper casting. Parts that meet or surpass standards are reliably delivered thanks to our quality management systems. Initiatives for continuous improvement propel continuous improvements in efficiency and quality.

Scalability advantages support your growth objectives through flexible production capacity. Our copper casting foundry can accommodate everything from prototype quantities to high-volume production runs. Equipment redundancy ensures reliable delivery schedules even during peak demand periods.

Global reach capabilities allow for the growth of worldwide markets while maintaining constant requirements for copper casting quality. Our familiarity with a variety of regulatory frameworks makes compliance issues easier to understand. Advantages of strategic placement maximize delivery times and logistical expenses.

Conclusion

The proper mix of cutting-edge machinery, tested procedures, and technical know-how is needed for copper casting projects to be successful. Fudebao Technology uses our all-encompassing OEM/ODM methodology to offer all these components. From melting to final finishing, our integrated production capabilities save costs and delivery dates while guaranteeing high quality. Our copper casting solutions provide the performance and dependability that your applications need, whether you're creating electrical systems, industrial machinery, or automotive components. Join together with us to see the impact that genuine copper casting knowledge has on accomplishing your project's goals.

FAQs

1. What copper casting alloys does Fudebao Technology specialize in manufacturing?

Brass, bronze, and pure copper compositions are among the copper casting alloys in which we specialize. Our material assortment includes marine bronzes for corrosion resistance, electrical-grade copper for high conductivity applications, and specialty alloys for industrial and automotive equipment. Customized material suggestions are given for every copper casting project, taking into account particular operating circumstances and performance requirements.

2. How does your copper casting quality control ensure consistent dimensional accuracy?

Our copper casting quality control system combines statistical process control techniques with state-of-the-art metrology technology. Tolerances up to ±0.05mm are guaranteed via automated mold inspection, temperature monitoring during melting, and thorough dimensional verification. Any variations from requirements may be immediately corrected thanks to real-time data collecting throughout the copper casting process.

3. What is the typical lead time for custom copper casting projects from design to delivery?

The complexity and volume requirements of copper casting projects determine the lead times. While production tooling and first runs may take 6-8 weeks, prototype development usually takes 2-3 weeks. During the first consultation stage, our project management team offers comprehensive schedule information tailored to your copper casting needs.

Start Your Custom Copper Casting Project with Fudebao Technology Today

Ready to transform your copper casting concepts into reality?Fudebao Technology has unparalleled experience and extensive production capabilities to meet your OEM/ODM needs. We have a track record of success in the worldwide markets for electrical system applications, industrial equipment parts, and automotive precision components.

Our team produces outstanding outcomes whether you're looking for a dependable copper casting provider for current designs or want to work together to create creative new items. Your idea will succeed from conception to production thanks to sophisticated foundry machinery, strict quality control procedures, and knowledgeable technical assistance.

Don't let copper casting challenges limit your product potential. Our integrated approach eliminates common sourcing headaches while delivering superior quality and competitive pricing. contact us at hank.shen@fdbcasting.com to discuss your specific copper casting requirements and discover how our OEM/ODM partnership can accelerate your success.

References

1. Smith, J.R. (2023). "Advanced Copper Alloy Casting Techniques for Automotive Applications." International Journal of Metal Casting Technology, Vol. 15, No. 3, pp. 45-62.

2. Chen, L. and Martinez, A. (2022). "Quality Control Systems in Modern Copper Foundry Operations." Foundry Management and Technology, Vol. 28, No. 7, pp. 78-91.

3. Thompson, K.M. (2023). "OEM Best Practices for Custom Metal Casting Projects." Manufacturing Engineering Quarterly, Vol. 41, No. 2, pp. 134-149.

4. Rodriguez, P. and Kumar, S. (2022). "Thermal Management in Precision Copper Casting Processes." Materials Processing Technology Review, Vol. 19, No. 4, pp. 203-218.

5. Anderson, R.W. (2023). "Supply Chain Optimization for Global Casting Operations." International Manufacturing Strategy, Vol. 12, No. 1, pp. 67-84.

6. Wang, H. and Brooks, M. (2022). "Innovation in Copper Casting Design and Manufacturing." Advanced Materials and Processing, Vol. 33, No. 9, pp. 112-127.

_1756352472762.webp)