OEM copper casting options for custom parts have changed the way that businesses handle their unique production needs. Modern copper castings have great electrical conductivity, rust resistance, and temperature management qualities that make them essential in the aircraft, automobile, industrial gear, and electrical industries. We at Fudebao Technology know that each part has a story to tell about how well it works and how carefully it was made. From coming up with the first idea to delivering the finished product, we have a lot of experience with copper alloy casts. This means that we can make sure that your unique parts are made to exact specs and to the highest quality standards.

Understanding OEM and ODM Excellence in Copper Manufacturing

There have been big changes in copper casting over the last ten years. OEM (Original Equipment Manufacturer) partnerships let businesses use specialized manufacturing skills without having to spend a lot of money on infrastructure. On the other hand, ODM (Original Design Manufacturer) ties let people work together to come up with new ways to cast copper.

Our building at Fudebao Technology is a great example of this change. We've put a lot of money into modern sand casting and investment casting processes that let us make parts with tolerances of up to 0.05 mm. This level of accuracy is especially important for automakers who need electrical housings that fit properly into engine areas that are getting smaller and smaller.

To make copper castings, you need to know a lot about metals. Copper metals have different qualities, ranging from bronze alloys that are better at resisting wear to pure copper, which is the best at conducting electricity. We choose the best products for each job by working closely with engineering managers and buying leaders.

At the molecule level, quality control starts. Our precision casts are put through a lot of tests, such as an X-ray, a measurement check, and a mechanical analysis. This all-around method makes sure that every copper casting part meets the unique needs of the industry and performs the same way throughout all production runs.

Our Comprehensive OEM Manufacturing Strengths

Twenty years of experience making copper have taught us that success depends on being able to combine many skills in a way that works well together. Our factory uses both old-fashioned sand casting methods and newer precision casting methods. This gives us a level of flexibility that not many copper casting suppliers can match.

All of what we do is based on research and development. Our engineering team works with clients from the first idea to the prototype stage. They use advanced modeling software to make sure the copper casting design is perfect before it goes into production. This method cuts development times by a large amount while still ensuring the best performance.

The dependability of our supply system is what keeps our business going. We keep strategic ties with copper alloy sources around the world, so we can always get the materials we need, even when the market changes. Our buying team keeps an eye on the global copper markets all the time to help clients deal with changing prices and stay within their project budgets.

When a business grows, scalability is still very important. Our production ability can handle small amounts for prototypes all the way up to large manufacturing runs. Our copper casting process can be changed to fit your needs in terms of time and quantity, whether you need fifty special electrical links or fifty thousand car brackets.

Industry standards aren't met by quality control methods for copper castings. We keep our licenses up to date for uses in the automobile, aircraft, and industrial sectors, and every package comes with full paperwork that can be used to track it. Before production starts, our quality teams work with clients to set review guidelines and acceptance standards.

Extensive Customization Capabilities for Every Industry

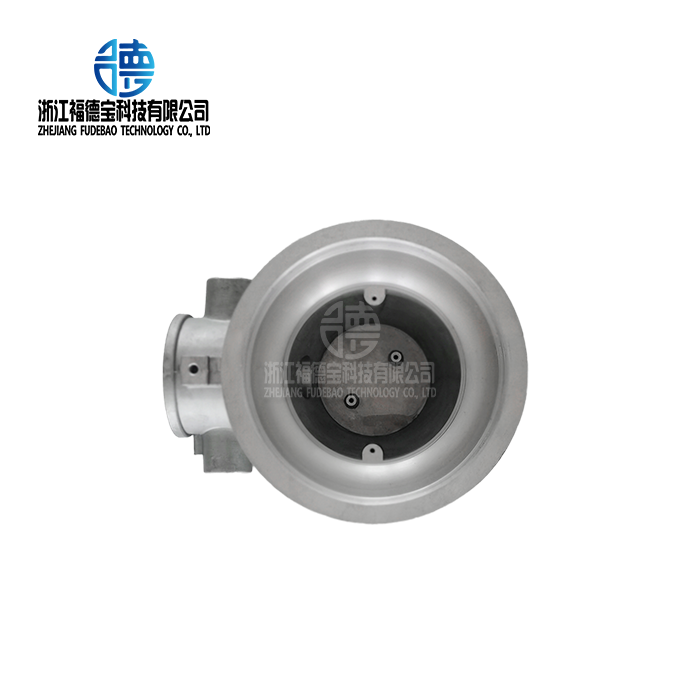

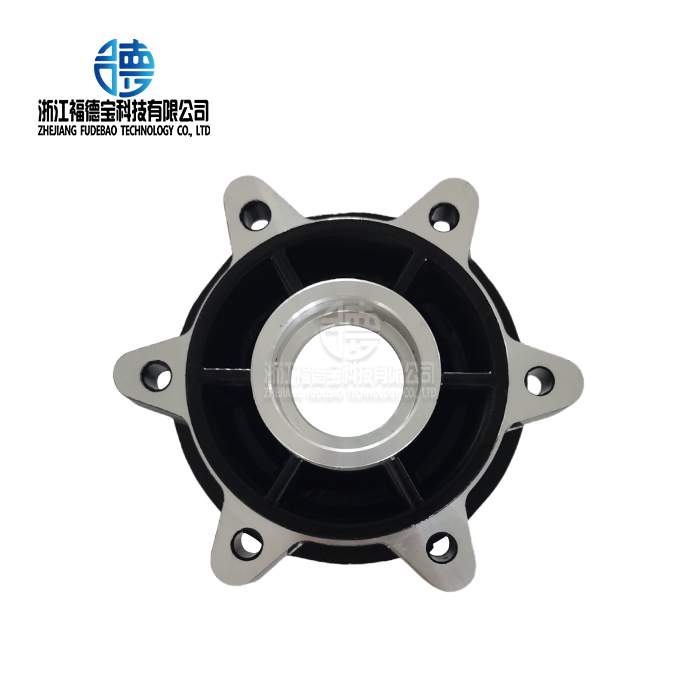

Customizing the physical form is just the start of what we can do. We regularly make parts that range from complicated electrical housings that weigh only a few grams to large industrial pump cases that weigh over one hundred pounds. Our sand casting and copper die casting methods can handle almost any physical complexity your application needs.

Customizing functional performance takes a deep knowledge of what the program needs. Certain heat-dissipation properties are needed for automotive thermal management parts, and electrical connections need exact conductivity values. Because we know a lot about metals, we can choose the best copper combination for each specific use.

We are different from other copper casting suppliers because we can combine different types of technology. We use modern machining tools and CNC processing right in our production process, so the parts we send out are finished and don't need much more work. This unified method cuts down on wait times while raising the quality of all the parts.

Permanent marking, numbering, and custom surface finishes are all ways to brand and identify something. A lot of clients need special part naming systems or legal marks that are built right into the made parts. These needs are effortlessly built into our copper casting mold design.

Compliance management for copper castings includes a lot of different industry standards, such as PPAP paperwork for the car industry, tracking rules for the aerospace industry, and electricity safety certifications. Our quality systems keep all of our certifications up to date for all important standards, which makes the approval process easier for you.

The Strategic ODM Partnership Advantage

ODM relationships open up new ideas that can't be done with standard source relationships. When clients come to us with performance goals instead of set plans, our engineering team uses decades of experience in copper casting metallurgy to come up with the best solutions.

Collaboration in development projects often leads to ground-breaking results. Copper casting uses made possible by new partnerships are 30% more efficient at using electricity than older designs. These gains come from choosing the right metal, using modern casting methods, and combining precision cutting.

Cost saving through collaborative design often comes as a surprise to clients. Our experts look for ways to combine several parts into single copper castings, which makes assembly easier and more reliable overall. These changes to the design often cut the total cost of the parts by a large amount.

When growth happens inside the company, it responds to changes in the market much more quickly. Instead of waiting months for outside approval of a design, ODM partnerships allow for quick testing and improvement over time. In competitive markets, where time-to-market is key to success, this flexibility is especially useful.

Protecting intellectual property is still the most important thing in all ODM interactions. We follow strict rules about privacy and have clear ownership agreements that keep your competitive benefits safe and allow us to work together effectively.

Our Streamlined Development and Production Process

The first meeting sets the goals for the project, the level of performance needed, and the expected schedule. Our expert team carefully goes over your specs, looking for ways to make them better and letting you know about any manufacturing issues early on.

Advanced CAD software and casting modeling tools are used in design development to predict how copper castings will behave before the tools are made. This virtual evaluation greatly lowers the risks of development while improving the performance of the end component.

Prototyping validation tests the design ideas to make sure they are correct. We make prototypes in large numbers using production-representative methods. This lets us fully test the shape, fit, and function of the products before investing in full-scale tools.

Preparing for production includes making thorough records of the process, following quality control rules, and coordinating the supply chain. During this time, our project managers keep in touch regularly to make sure a smooth transfer from development to mass production.

Delivery and help keep going even after the first package. We keep thorough records of our production, which lets us quickly meet future needs, whether they are for more products, changes to the design, or expert help.

Proven Benefits of Choosing Fudebao Technology Partnership

Our combined development method speeds up the time it takes to get a product to market. When compared to standard supply deals, clients usually cut project timelines by 40%. In competitive markets where early entry determines market share, this speed edge often makes all the difference.

There are several ways that cost efficiency can show up. Our design improvement often cuts down on the amount of material needed, and integrating the process gets rid of the need for extra handling and checking steps. Our connections in the global supply chain also help us keep material costs low.

In all copper casting uses, the quality is consistently higher than what is expected by the business. Our statistical process control systems keep thorough records of performance. This lets us keep improving while making sure that the results are always the same from batch to batch.

Technical help goes well beyond the original release. Our tech team is still ready to help with program advice, problems, and ideas for future improvements. This long-term connection often leads to more improvement projects and bigger companies.

Our thorough quality processes and many years of experience making things help us lower the risk. We look for problems before they happen and keep backup plans on hand to keep your production dates safe in case something goes wrong.

Conclusion

Copper casting's future lies in relationships that bring together technical know-how and top-notch production. Through our full OEM and ODM skills, Fudebao Technology is ready to turn your ideas for parts into reliable, high-performance products.

FAQs

Which copper metals do you use for one-of-a-kind casting jobs?

We work with a wide range of copper alloys, such as pure copper, bronze, brass, and special alloys like silicon bronze and aluminum bronze. Our metalworking team helps you choose the best materials for your purpose by taking into account things like electrical conductivity, rust resistance, and mechanical strength.

How can you make sure that the dimensions are correct when making copper?

As part of our quality control process, we use advanced measuring tools, statistical process control, and thorough checking methods. Tolerances of up to ±0.05mm are possible thanks to precise casting methods, controlled cooling processes, and CNC cutting that is built right in. These methods give us finished parts that are ready to be put together.

In what fields do you mostly provide copper casting solutions?

We work with original equipment manufacturers (OEMs) in the automotive industry who need electrical parts and thermal management parts, with electrical companies that make motor parts and connectors, and with aerospace applications that need high-strength, lightweight parts with full traceability documentation.

Partner with Fudebao Technology for Superior Copper Casting Solutions

The company that makes your copper castings should know both the technical needs and the business goals of your project. Fudebao Technology mixes advanced production skills with joint engineering help to turn ideas into parts that work well and are reliable.

Our full range of copper casting seller services cover all stages of designing and making parts. We have the skills and resources your project needs, from the initial concept advice to ongoing production support. Our team produces results that go above and beyond what you expect, whether you need electrical housings for cars, parts for industrial pumps, or custom flight uses.

Our method to every customer connection is based on quality, dependability, and teamwork. For your next copper casting job, we ask you to see what makes Fudebao Technology different. Email us at hank.shen@fdbcasting.com to talk about how our experience as a copper castings maker can help you meet your needs and meet your deadlines.

References

American Foundry Society. "Copper Alloy Casting Guidelines for Industrial Applications." Technical Bulletin Series, 2023.

Institute of Cast Metals Engineers. "Precision Casting Techniques in Modern Manufacturing." Professional Development Publication, 2023.International Copper Association. "Electrical Conductivity Standards for Copper Casting Applications." Industry Standards Manual, 2022.

Society of Automotive Engineers. "Material Specifications for Automotive Copper Components." SAE Technical Paper Series, 2023.

American Society for Testing and Materials. "Quality Control Methods in Metal Casting Operations." ASTM Standards Publication, 2023.

Manufacturing Engineering Society. "Advanced Casting Technologies in Global Supply Chains." Research Proceedings, 2022.

_1756346205762.webp)

_1756348780785.webp)

_1756352340434.webp)

_1756361323684.webp)