Copper Casting Cost Factors Buyers Should Know

2026-01-20

Making educated purchasing selections requires an awareness of the intricate price structure when investigating copper castings for your industrial applications. Copper castings are essential in the automotive, industrial equipment, electrical systems, and aerospace industries because to its remarkable heat conductivity, electrical qualities, and corrosion resistance. Final prices are greatly influenced by order sizes, production procedures, material composition, and post-processing needs. Although the initial expenditure may be more than alternatives, astute consumers understand that the long-term performance advantages often outweigh the cost. This detailed handbook explores critical pricing aspects that procurement professionals must address when buying copper-based components for their manufacturing processes.

Understanding Copper Castings and Their Cost Components

Copper castings are advanced metal parts produced using a variety of foundry techniques, each with unique benefits and financial ramifications. Procurement teams are better able to choose materials and allocate funds when they have a basic comprehension of these procedures.

Types of Copper Casting Methods

The casting process has a direct effect on production costs and quality results. The most cost-effective method for big, intricate geometries with modest accuracy requirements is still sand casting. This conventional technique, which uses sand mixes to create molds, is appropriate for low-volume production runs and prototypes when tooling costs must be kept to a minimum.

Investment casting, also referred to as lost-wax casting, provides excellent dimensional precision and surface qualities. Longer production cycles and specialized equipment are needed for this precise process, which raises the cost per unit. However, the high cost of complex components is often justified by the superb detail replication and low machining needs.

The ultimate in high-volume manufacturing efficiency is die casting. Only when the significant initial investment in steel tooling is distributed across large production volumes does it become cost-effective. This approach provides items with good dimensional uniformity and flawless surface finishes that minimize subsequent procedures.

Material Composition and Alloy Selection

Pure copper provides maximum electrical and thermal conductivity but has issues in mechanical strength and casting properties. Tin, aluminum, or other elements may be added to bronze alloys to improve strength and corrosion resistance while preserving excellent conductivity. Zinc-containing brass alloys provide reasonable cost, good machinability, and mild conductivity.

Since greater purity grades fetch premium price, the amount of copper content closely corresponds with material costs. Expensive alloying components included in specialty alloys made for particular uses, such high-temperature activities or marine conditions, have a big influence on material costs.

Process Complexity and Quality Standards

Geometric complexity, changes in wall thickness, and tolerance requirements are all included in casting complexity. Components with deep recesses, thin walls, or complicated internal pathways are much more expensive than simple geometries with homogeneous sections. Tight tolerances need extra process controls and inspection processes that raise production costs.

Pricing structures are impacted by the additional levels of paperwork, testing, and traceability that quality certifications mandated by the automotive, aerospace, and medical sectors contribute. These strict requirements guarantee component dependability, but they need for specific facilities and trained staff.

Core Cost Factors in Copper Casting Procurement

The ultimate cost structure for copper casting projects is determined by a number of interrelated factors. Procurement experts may bargain successfully and maximize their sourcing strategy by having a thorough understanding of these components.

Raw Material Pricing and Market Fluctuations

Commodity prices for copper are very volatile due to industrial demand patterns, economic considerations, and global supply situations. Although real procurement prices are influenced by supplier relationships and geographical considerations, London Metal Exchange pricing is the global standard. Tin, nickel, and aluminum are examples of alloy additives that have unique market characteristics that exacerbate price swings.

Procurement scheduling methods may dramatically effect material costs. Although long-term contracts provide pricing stability, they may also reduce flexibility in times of market decline. Spot purchase exposes businesses to price surges during supply shortages, yet also permits opportunistic buying.

Manufacturing Volume Economics

Because of economies of scale, production numbers have a significant impact on per-unit costs. Manufacturers may spread fixed costs across bigger volumes, minimize setup delays, and maximize furnace use with high-volume orders. Pricing and volume have a steep curve connection, and increasing numbers often results in significant cost savings per unit.

Minimum order numbers set by foundries reflect their operating needs and cost structures. Buyers may better manage inventory levels and achieve optimum price by structuring orders according to these parameters.

Post-Processing and Secondary Operations

Raw castings gain substantial value from machining needs, especially for precision applications requiring close tolerances. Material removal volumes, surface polish requirements, and geometric complexity all affect CNC machining costs. Heat treatment procedures improve mechanical qualities, but they need long processing durations and specific furnace operations.

Surface treatments include plating, coating, and anodizing give corrosion protection and cosmetic improvement. Additional handling, processing time, and quality control procedures are needed for these finishing processes, which raise costs all along the value chain.

Although they guarantee component compliance, quality inspection and testing procedures lengthen the production process and increase costs. Measurement equipment, material testing, and certification paperwork are examples of essential expenditures that affect ultimate price schemes.

Comparing Copper Castings With Other Materials for Cost Efficiency

Beyond the initial purchase price, careful consideration must be given to material selection considerations. Total cost of ownership factors include performance attributes, service life expectations, and maintenance needs that effect long-term value propositions.

Performance Versus Cost Analysis

Aluminum castings provide considerable weight benefits and reduced material costs but cannot match copper's thermal and electrical qualities. Applications that need electrical conductivity or heat dissipation often use copper's better performance qualities to justify its high price.

Steel castings are very strong and reasonably priced, but they don't have the conductivity and corrosion resistance of copper. Rather of relying only on cost comparisons, the selection of materials is based on performance goals and application-specific needs.

Custom Versus Standard Component Strategies

Although standard copper casting layouts save development times and tooling costs, they could not maximize performance for certain applications. Although they need significant upfront tooling and development expenditures, custom designs provide for performance optimization and competitive benefits.

To establish the best levels of customisation, the decision framework should assess production quantities, performance requirements, and competitive positioning. Balanced solutions are often offered by hybrid techniques that combine unique features with standard interfaces.

Environmental and Sustainability Considerations

Copper's remarkable recyclability generates long-term value via material recovery activities. Scrap copper maintains tremendous value, balancing early material inputs and promoting circular economy concepts. When end-of-life material recovery is possible, this feature becomes very useful for high-volume applications.

Decisions on the selection of materials are increasingly influenced by environmental standards. Copper's inherent antibacterial qualities and recyclability coincide with environmental efforts while avoiding regulatory problems connected with certain alternative materials.

Procurement Best Practices: Selecting Reliable Copper Castings Suppliers

The choice of supplier has a big influence on quality results and cost control. Successful collaborations that provide value beyond basic pricing concerns are ensured by thorough assessment criteria.

Quality Certification and Capabilities Assessment

Although ISO 9001 certification serves as the cornerstone of quality management, industry-specific standards like AS9100 for aerospace or TS 16949 for the automotive sector provide further assurance. These certifications show methodical ways to continuous development and quality management that lower risk and guarantee reliable results.

Evaluation of production capacity takes into account both present capabilities and potential expansion scalability. Suppliers with significant capacity margins can accept urgent orders and volume surges without sacrificing quality or delivery timelines.

Cost Transparency and Partnership Approaches

Long-term planning and efficient cost management are made possible by transparent pricing systems. When opposed to suppliers with strict price policies, those that are open to sharing cost breakdowns and working together on cost-cutting projects often provide better value.

Geographic factors weigh labor costs and production capacity against transportation expenses. While foreign suppliers could provide economic advantages for high-volume applications, domestic vendors offer communication advantages and shorter lead times.

Supply Chain Risk Management

Diversified supplier bases lessen reliance concerns and give power during negotiations. However, overseeing many suppliers requires more resources and might reduce the benefits of volume-based pricing. Depending on the volume needs and application criticality, the best strategy strikes a compromise between cost effectiveness and risk reduction.

Quality agreements providing explicit requirements, inspection processes, and performance indicators eliminate expensive misunderstandings and assure consistent results. These agreements provide the groundwork for fruitful, long-term collaborations.

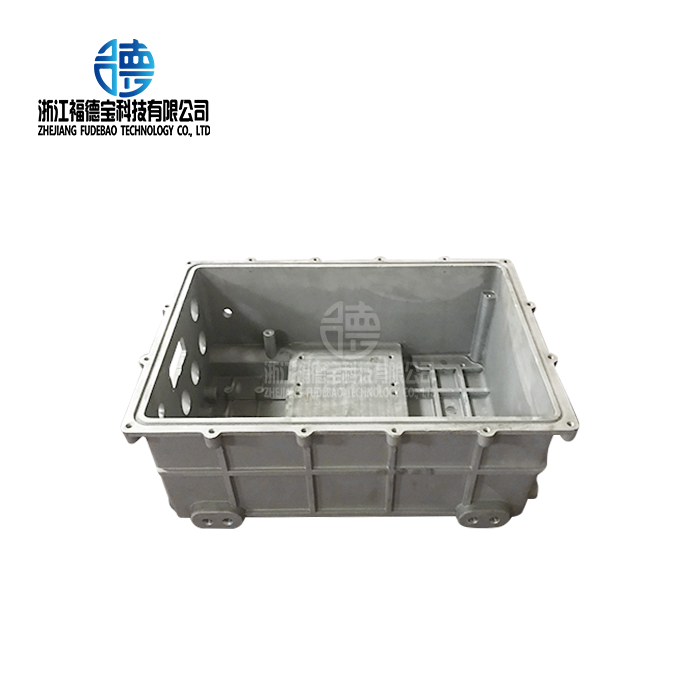

Fudebao Technology: Your Trusted Copper Castings Partner

Precision copper castings for demanding industrial applications in the automotive, equipment, and energy industries are the specialty of Zhejiang Fudebao Technology Co., Ltd. Our extensive production capabilities include precision machining, investment casting, and sand casting, which produce components that satisfy the highest quality standards.

Advanced Manufacturing Capabilities

Our facility is equipped with cutting-edge machinery, such as CNC lathes, high-speed machining centers, and specialist casting equipment, which guarantees dimensional precision within tolerances of ±0.05mm. We are especially well-suited for automotive precision parts, electrical housings, and energy sector components that need to be very accurate because of our precise competence.

Superior quality control and cost efficiency are made possible by the full process integration from melting to finishing. Our one-stop strategy guarantees constant quality throughout the production process while removing coordination challenges.

Quality Excellence and Certification

Component dependability and regulatory compliance are guaranteed by strict inspection procedures and international quality certifications. Our quality management solutions preserve efficiency for high-volume manufacturing while meeting traceability requirements for automotive and aerospace applications.

Design optimization for cost-effectiveness and manufacturing feasibility is aided by technical engineering assistance. Our knowledgeable staff works with clients to find value engineering options that lower expenses without sacrificing functionality.

Global Service and Support

Regardless of location, dependable delivery timetables are guaranteed by extensive logistical capabilities. Our knowledge in supply chain management enables clients to maintain production flexibility for changing demand patterns while optimizing inventory levels.

Flexible scheduling, prompt technical assistance, and proactive communication across project lifecycles are all components of excellent customer service. Long-term partnerships with top automakers, producers of industrial equipment, and energy corporations have been developed using this collaboration method.

Conclusion

Procurement experts may make well-informed choices that strike a balance between budgetary limitations and performance needs by having a thorough understanding of copper casting cost considerations. Total cost structures that go beyond straightforward unit price are influenced by a variety of factors, including supplier capabilities, production procedures, volume concerns, and material choices. Because of its improved performance, longer service life, and lower maintenance needs, copper castings' exceptional qualities often make premium expenditures worthwhile. Successful procurement strategies analyze these broad aspects while creating connections with competent suppliers that offer transparency, quality, and dependable delivery. Astute consumers understand that, especially in important applications where performance and dependability are still top priorities, the lowest initial price seldom offers the greatest long-term value.

FAQs

For copper castings, what are the main factors influencing cost?

The biggest cost factor is material composition, with alloying components and the amount of copper content having a big influence on price. Manufacturing complexity, including geometric characteristics and tolerance requirements, impacts processing costs. While post-processing procedures like machining and surface treatments offer significant value, order quantities provide economies of scale. Final price structures are also influenced by quality certifications and inspection requirements.

What impact do lead times have on the price of copper casting?

By enabling manufacturers to optimize production schedules and group comparable orders together, extended lead times usually result in lower costs. Rush orders entail quick processing, which raises labor expenses and could call for overtime. While shortened schedules often include premium fees that reflect the increased resources needed, standard lead times allow for greater capacity utilization and more advantageous pricing.

Are eco-friendly copper casting techniques more expensive?

Sustainable practices and environmental compliance procedures may raise processing costs initially, but they often provide long-term benefits via lower waste disposal costs and chances for material recovery. In fact, recycling initiatives and energy-efficient furnace operations can lower operating expenses while advancing sustainability objectives. Regulatory compliance and increased efficiency are two common benefits of investing in environmentally friendly procedures.

Partner with Fudebao Technology for Superior Copper Castings

Partnering with Zhejiang Fudebao Technology, your dependable supplier of copper castings with a focus on precise parts for industrial applications, can expedite your procurement process. From the processing of raw materials to the final machining, our integrated production skills provide economical solutions without sacrificing quality requirements. To discuss your particular needs and learn how our experience in the automotive, equipment, and energy sector applications may improve your component procurement strategy while lowering total ownership costs, get in touch with our engineering team at hank.shen@fdbcasting.com.

References

Smith, J.R. "Cost Analysis in Non-Ferrous Metal Casting: A Comprehensive Industrial Guide." Manufacturing Engineering Journal, 2023.

Thompson, M.K. and Peterson, L.A. "Material Selection Strategies for Electrical and Thermal Applications in Modern Manufacturing." Industrial Materials Review, 2023.

Brown, C.D. "Supply Chain Optimization in Metal Casting Procurement: Best Practices for B2B Buyers." Procurement Management Quarterly, 2022.

Davis, R.H. "Quality Certification Impact on Casting Costs in Automotive and Aerospace Industries." Quality Engineering International, 2023.

Wilson, S.T. "Environmental Considerations in Metal Casting: Sustainability and Cost Balance." Green Manufacturing Today, 2022.

Anderson, K.L. "Volume Economics and Pricing Strategies in Precision Metal Casting Operations." Industrial Economics Review, 2023.

YOU MAY LIKE

_1756349002499.webp)

_1756352712247.webp)