Aluminum Die Casting Cost Factors in 2026

2026-01-20

Metal die casting is a crucial manufacturing technique that produces components with remarkable surface quality and dimensional accuracy by injecting molten metal at high pressure into precisely designed molds. Due to shifting global supply chain dynamics, rising raw material prices, and technical advancements, aluminum die casting costs will continue to rise as we go through 2026. Procurement experts may make strategic sourcing choices that maximize quality and budget performance in automotive, industrial, electrical, and aerospace applications by having a thorough understanding of these cost factors.

Understanding Aluminum Die Casting and Its Cost Drivers

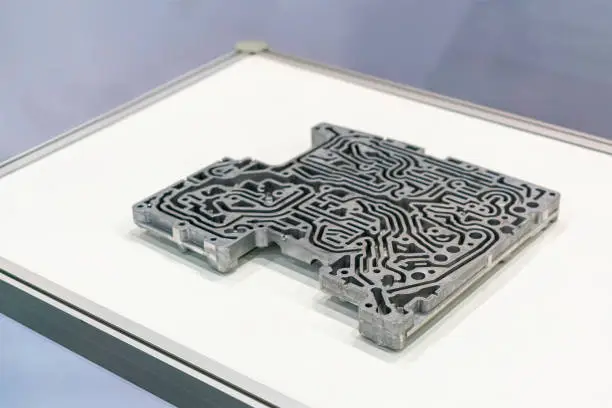

metal die casting creates intricate structures with precise tolerances and superior surface polish by pouring molten metal into specially designed molds using specialized equipment. With the addition of sophisticated temperature controls, real-time monitoring systems, and automated quality inspection capabilities, this production process has become more complex.

Core Process Components and Their Cost Implications

Overall production costs are directly impacted by the core components of die casting processes. Melting aluminum alloys at exact temperatures—usually between 650°C and 700°C—while preserving their ideal chemical composition is known as material preparation. Particularly with growing electricity bills in 2026, energy usage during this phase accounts for a significant share of operating expenditures.

Another major expense is tooling, where a large initial investment is needed for precision-machined steel molds. These instruments must be able to endure high-pressure injection pressures and frequent heat cycling while retaining dimensional accuracy throughout long manufacturing runs. Schedules for tool maintenance and replacement have a direct impact on costs per unit in a variety of volume situations.

Manufacturing Advantages and Cost Benefits

Aluminum alloys' lightweight qualities provide substantial value propositions in a variety of sectors. Weight reduction goals are advantageous for automotive applications, while aeronautical components take use of strength-to-weight ratios that surpass those of conventional materials. Manufacturers may attain economies of scale via rapid production cycles, which lower per-piece costs through effective throughput rates.

When contrasting aluminum die casting with other production techniques, the benefits of scalability become clear. Shorter cycle durations optimize equipment use, but high-volume production runs spread tooling expenditures across greater quantities. For procurement teams handling extensive component needs, these operational savings result in competitive price.

Comparative Cost Analysis: Aluminum Die Casting vs. Other Casting Methods

In this section, alternative methods such plastic injection molding, sand casting, gravity casting, and zinc die casting are contrasted with aluminum die casting. Procurement experts may assess total cost of ownership across different production settings by being aware of these variances.

Sand Casting and Gravity Casting Comparisons

Although sand casting involves more finishing steps and longer cycle times, it provides reduced tooling costs compared to aluminum die casting. While dimensional constraints need additional machining for precise applications, material waste rates are usually higher than those of die casting. Although gravity casting has a higher surface quality than sand casting, it does not have the benefits of high-pressure die casting in terms of production speed.

Although investment casting produces complicated shapes and excellent surface finishes, its multi-step processing requirements result in premium price. Compared to die casting alternatives, lead times are much longer, which makes it less appropriate for industrial and high-volume automotive applications where sourcing choices are influenced by delivery dates.

Material Selection and Alloy Cost Considerations

The choice of aluminum alloy has a major effect on both material prices and performance attributes. A380, A383, and A390 are common die casting alloys, and each has unique benefits for certain uses. While A390 offers improved wear resistance for engine components despite higher material prices, A380 offers superior castability and corrosion resistance.

In order to meet sustainability standards and perhaps lower raw material costs, new alloy formulas use recycled aluminum content. These environmentally friendly substitutes preserve mechanical qualities while promoting corporate environmental goals, which are increasingly influencing procurement choices made by large automakers and industrial producers.

Main Factors Affecting Aluminum Die Casting Costs in 2026

Changes in the price of materials, particularly aluminum and its alloys, continue to be a major cost variable that is impacted by geopolitical and global market trends. Foundry operations are still impacted by the price of aluminum on the London Metal Exchange, and throughout 2026, supply chain interruptions and energy expenses will cause more instability.

Raw Material Price Dynamics

The availability of energy in the main producing areas, trade rules, and the state of the world economy all influence primary aluminum pricing. As producers seek to satisfy sustainability goals and lessen their susceptibility to fluctuations in the price of raw materials, recycled aluminum content has grown in popularity. Procurement teams have more price predictability because secondary aluminum processing costs are typically more stable than those of primary production.

The independent price fluctuations of alloy additives like silicon, copper, and magnesium exacerbate changes in the total cost of materials. Due to competition for the same raw material sources from the semiconductor sector, silicon availability—especially high-purity grades needed for automotive applications—has become more volatile.

Design Complexity and Tooling Investments

Production difficulties and tooling costs are closely correlated with part complexity. While complicated designs with thin walls, deep draws, or intricate undercuts need sophisticated tooling solutions and longer development times, simple geometries with consistent wall thickness simplify mold complexity and reduce production problems.

Both the initial tooling investment and continuing production costs for aluminum die casting are greatly impacted by tolerance requirements. Premium tool steels, precise machining, and strict maintenance schedules are required for automotive precision parts that need an accuracy of ±0.05mm. When compared to industrial applications with normal tolerance demands, these constraints increase the cost of tooling.

Technology Integration and Automation Advances

Although they demand a large initial investment, advanced process controls and automation systems provide long-term economic savings via increased productivity, decreased scrap rates, and greater uniformity. By identifying quality problems early on, real-time monitoring systems save faulty components from undergoing costly finishing procedures.

By using digital twin technology, manufacturers may improve process parameters before to the start of physical production, which lowers development costs and speeds up the time it takes for new components to reach the market. These technology capabilities are competitive advantages that provide discriminating procurement experts with higher value and support premium pricing.

Procurement Considerations: How to Manage and Reduce Die Casting Costs

The key to efficient cost control in the procurement of aluminum die casting is to choose producers that have a track record of success, certifications, and geographical advantages that complement supply chain objectives. Opportunities for cost minimization without sacrificing quality standards are created by strategic supplier partnerships based on openness and understanding.

Supplier Selection Criteria and Cost Optimization

Production capacity, quality certifications, and equipment specifications should all be included in the manufacturing capability evaluation. While TS 16949 certification particularly addresses the needs of the automobile sector, ISO 9001 certification offers a baseline level of quality assurance. For sophisticated processes, aerospace applications could need both NADCAP accreditation and AS9100 certification.

Geographical closeness affects delivery flexibility and logistical costs, which are crucial for just-in-time production settings. While overseas sources could provide comparable pricing for high-volume applications where logistical costs become less relevant in relation to per-piece savings, domestic suppliers often offer shorter lead times and lower transit costs.

Volume Strategies and Long-term Partnerships

Manufacturers of aluminum die casting may attain mutually beneficial economies of scale by volume consolidation across many part numbers. Annual volume commitments provide suppliers certainty in their production schedules, which often leads to advantageous pricing arrangements that acknowledge the lower business risk connected with fixed volumes.

The following are the main benefits of strategic volume planning:

- Tooling amortization benefits: By spreading out initial tool expenses across a larger number of parts, higher volumes lower tooling costs per piece and enhance project economics.

- Increases in production efficiency: Extended production runs optimize equipment use while lowering setup expenses and turnaround times.

- Material buying leverage: Suppliers may bargain for lower raw material prices via consolidated quantities, which results in competitive component costs.

- Improvements in quality consistency: Longer production runs keep the process stable and minimize fluctuation, producing results of higher quality.

These volume tactics provide win-win situations in which customers get competitive price and dependable delivery performance while suppliers gain business predictability. Collaborative design optimization and continuous improvement programs are common ways that long-term collaborations based on these foundations provide further advantages.

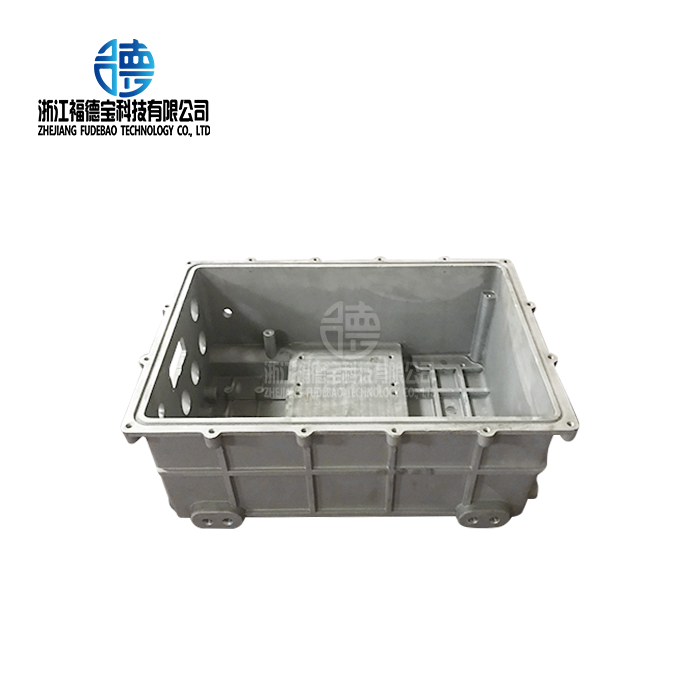

Company Introduction and Our Aluminum Die Casting Solutions

Zhejiang Fudebao Technology Co., Ltd. has made a name for itself as a top producer with precise machining skills, specialized in copper alloy, stainless steel casting, and aluminum alloy. Our extensive production facility provides components that satisfy the most exacting criteria to the worldwide automotive, industrial equipment, machinery, and aerospace sectors.

Manufacturing Capabilities and Quality Standards

High-speed machining centers, CNC lathes, low-pressure casting machines, and precision die casting equipment are among the cutting-edge pieces of machinery in our firm. This integrated method allows for one-stop supply from raw materials to final products with precision up to ±0.05mm, covering the whole production process from melting to casting, finishing, and surface treatment.

We uphold strict quality control procedures that facilitate the production of precise parts for automobiles, housings for medical equipment, and aerospace parts that need the highest level of dependability. Comprehensive inspection procedures, statistical process control, and complete traceability documentation that satisfies international requirements are all part of our quality management systems.

Direct Supply Relationships and Global Reach

Our dedication to being a leading aluminum foundry company is shown by our progression from intermediary collaboration to direct supply relationships with American HAAS automation machine tools, ESS energy storage batteries, and other global brands. Through enhanced quality and competitive pricing, these partnerships provide our clients access to state-of-the-art technologies and manufacturing best practices.

Flexible product development assistance is made possible by rapid prototyping and low-volume production capabilities, which let clients test concepts and streamline manufacturing procedures prior to making large tooling expenditures. This strategy shortens the time to market for innovative goods across a variety of industrial applications while lowering development risks.

Conclusion

A thorough examination of supplier capabilities, design complexity, technological integration, and material price is necessary to comprehend aluminum die casting cost variables in 2026. The main cost factors influencing procurement choices in automotive, industrial, electrical, and aerospace applications are raw material volatility, tooling investments, and process optimization.

Strategic supplier relationships that are based on quality excellence, volume commitments, and ongoing improvement provide long-term cost benefits while upholding the dependability and dimensional accuracy standards necessary for mission-critical components. The sector is still changing as a result of technology integration via automation and digital process controls, which offers chances for increased productivity and lower total cost of ownership.

FAQ

What impact do material selections have on the price of aluminum die casting?

The choice of aluminum alloy has a big influence on processing needs and material prices. While specialty alloys like A390 charge higher prices but provide improved performance for demanding applications, standard alloys like A380 provide outstanding castability and affordable pricing. Recycled aluminum content may help achieve sustainability goals while lowering material costs.

Which design elements have the most effects on die casting costs?

The main design elements influencing costs are tolerance requirements, wall thickness uniformity, and part complexity. While tight tolerances need precise tooling and improved process controls, which raise both the initial investment and continuing production costs, simple geometries with uniform wall thickness simplify tooling complexity and lower failure rates.

How can procurement teams lower the cost of aluminum die casting?

The best methods for cutting costs include volume consolidation, long-term supplier relationships, and early design cooperation. While design optimization throughout development stages saves expensive adjustments after tooling completion, annual volume commitments allow suppliers to provide competitive prices.

Partner with Fudebao Technology for Cost-Effective Aluminum Die Casting Solutions

Find out how Fudebao Technology's cutting-edge production skills can maximize your aluminum die casting expenses while providing outstanding quality. Complete component manufacture with a precision of up to ±0.05mm is made possible by our integrated facility, which combines CNC machining centers with precision die casting equipment.

As your go-to source for aluminum die casting, we provide flexible volume production, quick prototyping, and thorough quality documentation that satisfies industrial, automotive, and aerospace requirements. For a thorough cost analysis for your next project and to discuss your unique needs, get in touch with hank.shen@fdbcasting.com.

References

American Foundry Society. "Die Casting Industry Economic Trends and Cost Analysis 2026." Foundry Management & Technology Journal, 2026.

North American Die Casting Association. "Material Cost Fluctuations and Their Impact on Manufacturing Economics." Industrial Casting Report, 2026.

International Journal of Advanced Manufacturing Technology. "Automation Technologies and Cost Optimization in Modern Die Casting Operations." Manufacturing Engineering Research, 2026.

Automotive Industry Action Group. "Supplier Selection Criteria and Cost Management Strategies for Die Cast Components." Procurement Best Practices Guide, 2026.

Materials Science and Engineering Institute. "Aluminum Alloy Development and Cost-Performance Analysis for Industrial Applications." Metallurgical Quarterly, 2026.

Global Manufacturing Competitiveness Council. "Supply Chain Optimization and Cost Reduction Strategies in Metal Casting Industries." Manufacturing Excellence Review, 2026.

YOU MAY LIKE

_1756345939856.webp)

_1756348227989.webp)

_1756352400994.webp)