The Synergy of Casting and CNC Machining

Understanding the Casting Process

Casting is a manufacturing process that has been used for thousands of years to create metal parts. It involves pouring molten metal into a mold and allowing it to solidify. This method is particularly useful for producing complex shapes that would be difficult or impossible to create through other means. There are several types of casting processes, including:

- Sand casting

- Investment casting

- Die casting

- Low-pressure casting

Each of these methods has its own advantages and is suited for different applications. For example, sand casting is versatile and cost-effective for large parts, while die casting is ideal for high-volume production of smaller components.

The Precision of CNC Machining

CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece. This method offers exceptional precision and repeatability, making it ideal for creating parts with tight tolerances. CNC machines can perform various operations, including:

- Milling

- Turning

- Drilling

- Grinding

These capabilities allow manufacturers to produce parts with complex geometries and high-quality surface finishes. CNC machining is particularly valuable in industries that require extreme accuracy, such as aerospace and medical device manufacturing.

The Power of Hybrid Manufacturing

By combining casting and CNC machining, manufacturers can leverage the strengths of both processes. Casting allows for the creation of near-net-shape parts with complex internal geometries, while CNC machining provides the precision necessary to achieve tight tolerances and superior surface finishes. This hybrid approach offers several benefits:

- Reduced material waste

- Shorter production times

- Improved part quality

- Greater design flexibility

Hybrid manufacturing is particularly useful for producing large, complex parts that require both the forming capabilities of casting and the precision of CNC machining.

Advantages of Hybrid Manufacturing

Cost-Effectiveness and Efficiency

One of the primary advantages of combining casting and CNC machining is the potential for significant cost savings. By using casting to create near-net-shape parts, manufacturers can reduce the amount of material that needs to be removed through CNC machining. This results in:

- Lower raw material costs

- Reduced machining time

- Decreased tool wear

Additionally, the hybrid approach can lead to faster production times, as the casting process can quickly produce multiple parts that require only minimal machining to achieve final specifications.

Enhanced Design Flexibility

Hybrid manufacturing opens up new possibilities for product design. The combination of casting and CNC machining allows engineers to create parts with:

- Complex internal geometries

- Thin walls

- Undercuts and other challenging features

This enhanced design flexibility can lead to improved product performance, reduced weight, and optimized material usage. For example, in the automotive industry, hybrid manufacturing can be used to create lightweight yet strong components that contribute to improved fuel efficiency.

Improved Quality and Precision

By leveraging the strengths of both casting and CNC machining, hybrid manufacturing can produce parts with exceptional quality and precision. The casting process creates a near-net-shape part, while CNC machining refines critical features to meet tight tolerances. This combination results in:

- Higher dimensional accuracy

- Improved surface finishes

- Consistent part quality across production runs

These quality improvements are particularly valuable in industries such as aerospace and medical device manufacturing, where part performance and reliability are critical.

Applications and Industry Impact

Automotive Industry

The automotive sector has embraced hybrid manufacturing to produce complex engine components, transmission parts, and structural elements. This approach allows for the creation of lightweight, high-strength parts that contribute to improved fuel efficiency and vehicle performance. Some examples of automotive applications include:

- Engine blocks

- Cylinder heads

- Transmission housings

- Suspension components

By using hybrid manufacturing, automotive manufacturers can reduce production costs while improving part quality and performance.

Aerospace and Defense

In the aerospace and defense industries, hybrid manufacturing is used to create complex, high-performance components that must meet stringent quality and reliability standards. This approach is particularly valuable for producing:

- Turbine blades

- Structural airframe components

- Satellite parts

- Missile components

The combination of casting and CNC machining allows aerospace manufacturers to create parts with optimized geometries that reduce weight without compromising strength or durability.

Medical Device Manufacturing

The medical device industry benefits from hybrid manufacturing's ability to produce complex, precision components with biocompatible materials. This approach is used to create:

- Orthopedic implants

- Surgical instruments

- Dental prosthetics

- Medical imaging equipment components

Hybrid manufacturing enables medical device manufacturers to produce patient-specific implants and devices with improved functionality and durability.

Conclusion

Combining casting and CNC machining for hybrid manufacturing represents a significant advancement in manufacturing technology. This approach offers numerous benefits, including cost savings, enhanced design flexibility, and improved part quality. As industries continue to demand more complex and precise components, hybrid manufacturing is poised to play an increasingly important role in meeting these challenges. By leveraging the strengths of both casting and CNC machining, manufacturers can create parts that were previously impossible or impractical to produce, opening up new possibilities for innovation and product development across various industries.

FAQs

What are the main advantages of combining casting and CNC machining?

The main advantages include reduced material waste, shorter production times, improved part quality, and greater design flexibility.

Which industries benefit most from hybrid manufacturing?

Automotive, aerospace, defense, and medical device industries benefit significantly from this approach due to their need for complex, high-precision parts.

How does hybrid manufacturing improve cost-effectiveness?

It reduces raw material costs, decreases machining time, and minimizes tool wear by creating near-net-shape parts through casting before precision machining.

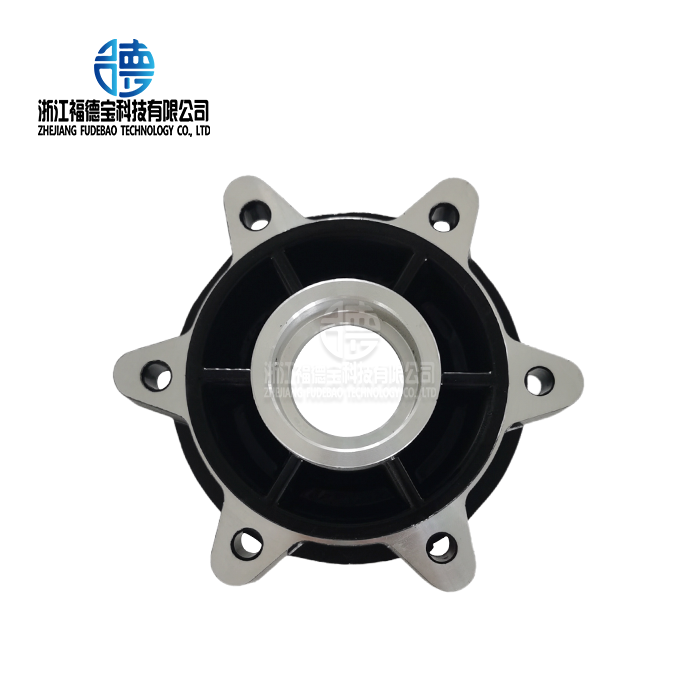

Expert Hybrid Manufacturing Solutions | Fudebao Technology

At Fudebao Technology, we specialize in combining casting and CNC machining for hybrid manufacturing solutions. As a leading supplier and manufacturer, we offer cutting-edge capabilities in aluminum alloy, copper alloy, and stainless steel processing. Our state-of-the-art facility ensures precision up to ±0.05mm, meeting the highest industry standards. For expert hybrid manufacturing solutions, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advances in Hybrid Manufacturing Techniques. Journal of Manufacturing Technology, 45(3), 278-295.

Johnson, A., & Brown, T. (2021). The Future of Precision Engineering: Combining Casting and CNC Machining. International Journal of Industrial Engineering, 18(2), 112-128.

Lee, S., et al. (2023). Cost-Effectiveness Analysis of Hybrid Manufacturing in Automotive Applications. Automotive Engineering Review, 37(4), 567-582.

Zhang, L., & Wilson, R. (2022). Hybrid Manufacturing Techniques in Aerospace: A Comprehensive Review. Aerospace Science and Technology, 29(1), 45-63.

Garcia, M., et al. (2023). Advancements in Medical Device Manufacturing Through Hybrid Processes. Journal of Biomedical Engineering, 52(3), 321-337.

Anderson, P. (2021). The Role of Hybrid Manufacturing in Industry 4.0. Manufacturing Technology Today, 14(2), 78-93.

_1756346310015.webp)

_1756352625880.webp)

_1756361494985.webp)