Understanding CNC Machining Precision and Surface Finish

The Fundamentals of CNC Machining Accuracy

CNC machining accuracy refers to the degree of conformity between the manufactured part and its design specifications. It's influenced by various factors, including machine calibration, tool wear, and environmental conditions. Achieving high accuracy in CNC machining requires a combination of precise equipment, skilled operators, and robust quality control processes.

One key aspect of CNC machining accuracy is tolerances. Tolerances define the acceptable range of deviation from the specified dimensions. Tighter tolerances generally indicate higher precision but may also increase production costs. It's essential to balance the required accuracy with manufacturing feasibility and cost-effectiveness.

Another critical factor in CNC machining accuracy is repeatability. This refers to the machine's ability to produce identical parts consistently. High repeatability ensures uniform quality across production runs, which is crucial for mass production and interchangeable components.

Surface Roughness in CNC Machined Parts

Surface roughness is a measure of the texture of a machined surface. It's typically quantified using parameters like Ra (arithmetic average roughness) or Rz (maximum height of the profile). The surface finish of CNC machined parts can significantly impact their functionality, appearance, and performance in various applications.

Different machining operations and parameters can result in varying levels of surface roughness. For instance, milling typically produces a smoother finish than turning, while the use of different cutting tools, feed rates, and spindle speeds can all affect the final surface texture.

Understanding the relationship between machining parameters and surface finish is crucial for achieving the desired results. For example, higher cutting speeds generally produce smoother surfaces, but may also lead to increased tool wear. Balancing these factors is key to optimizing both surface quality and production efficiency.

The Importance of Accuracy and Surface Finish in Various Industries

Accuracy and surface finish play critical roles in numerous industries. In aerospace, precision-machined components ensure the safety and performance of aircraft. The automotive industry relies on accurate parts for engine efficiency and vehicle reliability. Medical devices require extremely precise components to function correctly and ensure patient safety.

Surface finish is particularly important in applications involving fluid dynamics, such as in hydraulic systems or aerodynamic surfaces. A smooth finish can reduce friction, improve energy efficiency, and extend the lifespan of components. In consumer products, surface finish contributes to aesthetics and tactile quality, influencing customer perception and satisfaction.

Moreover, both accuracy and surface finish can impact the assembly process. Parts that are too rough or inaccurate may not fit together properly, leading to issues in product functionality or increased assembly time and costs. Therefore, maintaining high standards in these areas is essential for overall product quality and manufacturing efficiency.

Essential Tools and Techniques for Inspecting CNC Machined Parts

Measurement Instruments for Dimensional Accuracy

Ensuring dimensional accuracy in CNC machining parts requires a range of specialized measurement tools. Calipers are versatile instruments used for measuring linear dimensions, both internal and external. They come in various types, including digital, vernier, and dial calipers, each offering different levels of precision.

Micrometers are another crucial tool, providing even higher accuracy for measuring thicknesses and diameters. They use a precision screw mechanism to achieve measurements accurate to within a few micrometers. For complex geometries, coordinate measuring machines (CMMs) offer unparalleled precision. CMMs can measure three-dimensional features and generate detailed reports on part conformity.

Optical comparators and vision systems are invaluable for inspecting 2D profiles and features that are difficult to measure with contact methods. These tools project an enlarged image of the part, allowing for quick and accurate comparison against a template or digital overlay.

Surface Roughness Measurement Methods

Measuring surface roughness requires specialized equipment designed to quantify the microscopic variations in surface texture. Contact profilometers are widely used instruments that drag a stylus across the surface, recording its vertical displacement to create a surface profile. This method provides detailed information about surface characteristics but can be time-consuming for large areas.

Non-contact methods, such as optical profilometers, offer faster measurement without risking damage to delicate surfaces. These instruments use light interference patterns to create a 3D map of the surface. While generally less precise than contact methods, they excel at measuring larger areas quickly.

Portable surface roughness testers provide a convenient option for on-site measurements. These handheld devices offer quick results and are particularly useful for large parts or in-process checks. However, they may not provide the same level of detail as laboratory-grade equipment.

Advanced Inspection Technologies

The field of metrology is constantly evolving, with new technologies enhancing the inspection process. 3D scanning technologies, such as laser and structured light scanners, can rapidly capture the entire geometry of a part. This data can be compared against the original CAD model to identify deviations across the entire surface.

X-ray computed tomography (CT) scanning is gaining popularity for inspecting internal features of complex parts. This non-destructive testing method can reveal hidden defects, measure wall thicknesses, and verify internal geometries that are otherwise inaccessible.

Artificial intelligence and machine learning are also being integrated into inspection processes. These technologies can analyze large datasets from multiple inspection methods, identifying trends and potential issues that might be missed by human inspectors. This approach not only improves accuracy but also enhances efficiency in quality control processes.

Best Practices for Implementing Quality Control in CNC Machining

Establishing a Comprehensive Inspection Plan

A robust inspection plan is the foundation of effective quality control in CNC machining. This plan should outline the specific measurements and tests to be performed, their frequency, and the acceptance criteria for each feature. It's crucial to align the inspection plan with the part's design specifications and intended function.

Start by identifying critical features that are essential to the part's performance. These may include dimensions with tight tolerances, surface finish requirements, or specific geometric relationships. Determine the appropriate inspection methods and tools for each feature, considering factors like accuracy requirements and production volume.

Incorporate both in-process and final inspections into your plan. In-process checks can catch issues early, reducing waste and rework. Final inspections ensure that the completed parts meet all specifications before being released to the customer. Don't forget to include provisions for handling non-conforming parts and implementing corrective actions when issues are identified.

Training and Calibration for Consistent Results

The effectiveness of your inspection process relies heavily on the skills of your quality control team and the accuracy of your measurement equipment. Invest in comprehensive training programs for your inspectors, covering not only the use of measurement tools but also the interpretation of results and understanding of manufacturing processes.

Regular calibration of all measurement instruments is crucial to maintain accuracy over time. Develop a calibration schedule based on the manufacturer's recommendations and the frequency of use. Keep detailed records of calibration activities and results to ensure traceability and compliance with quality standards.

Consider implementing a system of measurement system analysis (MSA) to evaluate the reliability of your inspection processes. This involves assessing factors like repeatability, reproducibility, and bias in your measurements. By understanding the limitations of your inspection methods, you can make informed decisions about process improvements and measurement equipment upgrades.

Integrating Quality Control with Production Processes

To maximize efficiency and effectiveness, quality control should be seamlessly integrated into your production workflow. Implement statistical process control (SPC) techniques to monitor key parameters in real-time. This approach allows you to detect trends and variations early, enabling proactive adjustments to maintain quality.

Leverage the capabilities of modern CNC machines by incorporating in-machine probing and measurement. Many advanced CNC systems can perform basic measurements during the machining process, allowing for immediate corrections and reducing the need for separate inspection steps.

Finally, establish clear communication channels between quality control, production, and engineering teams. Regular meetings to review inspection data, discuss challenges, and implement improvements can foster a culture of continuous improvement. This collaborative approach ensures that quality control isn't just a final checkpoint but an integral part of the entire manufacturing process.

Conclusion

Inspecting CNC machined parts for accuracy and roughness is a critical process that ensures the quality and reliability of manufactured components. By understanding the fundamentals of CNC machining precision and surface finish, utilizing the right tools and techniques, and implementing best practices in quality control, manufacturers can consistently produce high-quality parts that meet or exceed customer expectations. Remember, effective inspection is not just about detecting defects but also about continuous improvement of the entire manufacturing process. As technology advances, staying updated with the latest inspection methods and integrating them into your workflow will be key to maintaining a competitive edge in the precision machining industry.

FAQs

How often should CNC machined parts be inspected?

The frequency of inspection depends on factors like part complexity, production volume, and criticality. Generally, it's recommended to perform in-process checks and final inspections for each batch. Critical features may require 100% inspection, while less critical ones might use sampling methods.

What's the difference between accuracy and precision in CNC machining?

Accuracy refers to how close a measurement is to the true value, while precision relates to the consistency of measurements. In CNC machining, high accuracy means parts closely match design specifications, while high precision ensures consistent results across multiple parts.

How does surface roughness affect part performance?

Surface roughness can impact various aspects of part performance, including friction, wear resistance, and fatigue strength. Smoother surfaces generally provide better performance in applications involving moving parts or fluid dynamics.

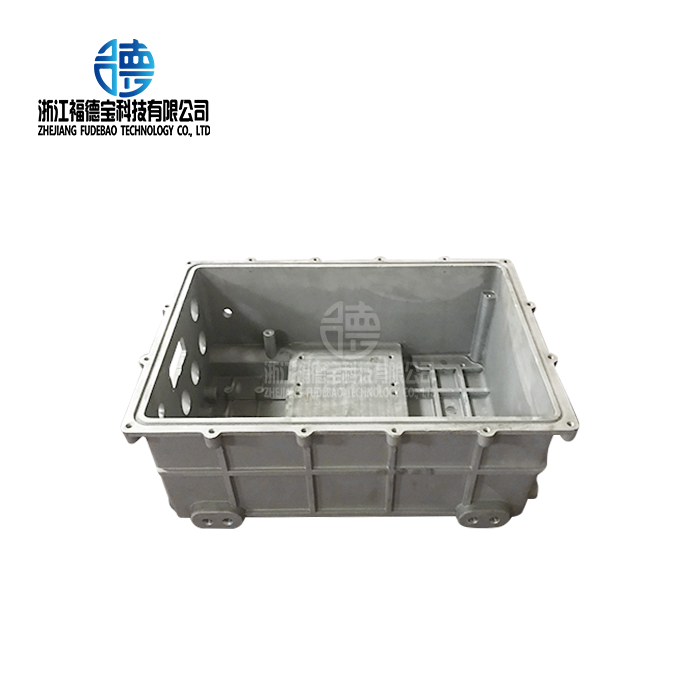

Expert CNC Machining Inspection Services | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining and rigorous quality control processes. Our state-of-the-art inspection equipment and experienced team ensure that every part meets the highest standards of accuracy and surface finish. As a leading supplier and manufacturer in the industry, we offer comprehensive solutions for your CNC machining needs. Contact us at hank.shen@fdbcasting.com to learn how we can help you achieve superior quality in your precision parts.

References

Smith, J. (2022). Advanced Techniques in CNC Machining Inspection. Journal of Manufacturing Technology, 45(3), 218-230.

Johnson, A., & Williams, R. (2021). Surface Roughness Measurement: A Comprehensive Guide. Precision Engineering Quarterly, 18(2), 75-90.

Brown, M. et al. (2023). Quality Control Strategies for High-Precision CNC Machining. International Journal of Industrial Manufacturing, 56(4), 302-315.

Lee, S., & Park, H. (2020). Innovations in Non-Contact Surface Metrology. Advanced Materials Processing, 29(1), 45-58.

Garcia, R. (2022). The Impact of Artificial Intelligence on CNC Machining Inspection Processes. Automation in Manufacturing, 37(2), 180-195.

Taylor, E. (2021). Best Practices for Implementing Statistical Process Control in CNC Machining. Quality Assurance in Manufacturing, 42(3), 240-255.

_1756346371362.webp)

_1756346421748.webp)

_1756348300182.webp)

_1756352400994.webp)