Understanding CNC and Traditional Machining Processes

The Evolution of Machining Technology

The manufacturing industry has come a long way since the days of manual lathes and mills. The evolution of machining technology has been driven by the need for greater precision, efficiency, and consistency in producing parts. Traditional machining methods, while still valuable in certain scenarios, have largely been superseded by computer numerical control (CNC) machining in many applications.

CNC machining represents a significant leap forward in manufacturing technology. It integrates computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to control machine tools automatically. This integration allows for complex shapes and designs that were once impossible or impractical to produce using traditional methods.

The transition from traditional to CNC machining has not been overnight. It's been a gradual process, with each advancement building upon previous innovations. Today, CNC machining is at the forefront of modern manufacturing, offering unparalleled precision and repeatability.

Key Differences Between CNC and Traditional Machining

The fundamental difference between CNC and traditional machining lies in the level of automation and control. Traditional machining relies heavily on the skill and experience of the machinist. The operator must manually control the machine, adjusting speeds, feeds, and tool paths based on their judgment and expertise.

In contrast, CNC machining automates these processes. Once a program is created and loaded into the CNC machine, it can reproduce parts with high consistency and minimal human intervention. This automation not only increases precision but also allows for complex operations to be performed repeatedly without fatigue or variation.

Another key difference is the range of operations that can be performed. While traditional machines are often limited to simpler cuts and shapes, CNC machines can perform intricate 3D machining, threading, and even multi-axis operations in a single setup. This versatility makes CNC machining ideal for producing complex parts with tight tolerances.

Applications and Industries

Both CNC and traditional machining have their place in modern manufacturing. CNC machining excels in industries that require high precision, complex geometries, or large production runs. It's commonly used in aerospace, automotive, medical device manufacturing, and high-tech industries where part accuracy is critical.

Traditional machining, on the other hand, remains valuable for small batch production, prototype development, and in situations where the cost of CNC programming and setup isn't justified. It's still widely used in repair shops, small-scale manufacturing, and for producing simple parts where extreme precision isn't necessary.

The choice between CNC and traditional machining often depends on factors such as production volume, part complexity, required accuracy, and budget constraints. Many modern manufacturing facilities maintain both CNC and traditional machines to cater to a wide range of production needs.

Accuracy Comparison: CNC vs. Traditional Machining

Precision Capabilities of CNC Machining

CNC machining stands out for its exceptional precision capabilities. Modern CNC machines can achieve tolerances as tight as ±0.0001 inches (about 2.5 microns). This level of accuracy is made possible by the integration of advanced control systems, high-precision ball screws, and sophisticated feedback mechanisms.

The precision of CNC machining isn't just about tight tolerances; it's also about consistency. Once a CNC program is optimized, it can produce hundreds or thousands of identical parts with minimal variation. This repeatability is crucial in industries like aerospace and medical device manufacturing, where even slight deviations can have serious consequences.

Moreover, CNC machines can maintain this high level of accuracy across complex, multi-axis operations. They can perform intricate 3D machining, creating parts with complex geometries that would be extremely difficult, if not impossible, to produce using traditional methods.

Accuracy Limitations in Traditional Machining

Traditional machining, while still capable of producing quality parts, generally can't match the precision of CNC machining. The accuracy of traditional machining is largely dependent on the skill of the operator and the condition of the machine. Even the most experienced machinists typically achieve tolerances of around ±0.005 inches.

The limitations of traditional machining become more apparent when dealing with complex parts or those requiring tight tolerances compared to CNC machining. Human factors such as fatigue, variations in technique, and the need for multiple setups can all contribute to reduced accuracy and consistency.

Furthermore, traditional machines often lack the advanced measurement and feedback systems found in CNC machines. This means that errors or deviations may not be detected until after the part is completed, potentially leading to wasted materials and time.

Factors Affecting Machining Accuracy

Several factors influence the accuracy of both CNC and traditional machining processes. Understanding these can help in choosing the right method for a particular application:

1. Machine Rigidity: The structural integrity of the machine affects its ability to maintain accuracy, especially under heavy cutting loads.

2. Tool Wear: As cutting tools wear, they can affect the dimensional accuracy of the parts being produced.

3. Thermal Expansion: Temperature changes can cause materials and machine components to expand or contract, affecting precision.

4. Vibration: Excessive vibration can lead to poor surface finish and reduced accuracy.

5. Material Properties: The hardness, elasticity, and thermal properties of the workpiece material can impact machining accuracy.

6. Operator Skill: In traditional machining, the operator's expertise plays a crucial role in achieving accurate results.

7. Programming and Setup: For CNC machining, the quality of the CAM programming and initial machine setup are critical for accuracy.

By considering these factors, manufacturers can make informed decisions about which machining method will best meet their accuracy requirements for specific projects.

Cost Analysis: CNC vs. Traditional Machining

Initial Investment and Setup Costs

The initial investment for CNC machining is generally higher than for traditional machining. CNC machines are more complex, incorporating advanced control systems, motors, and software. A high-end CNC machining center can cost several hundred thousand dollars, while a traditional manual lathe or mill might cost a fraction of that.

Setup costs for CNC machining include not just the machine itself, but also software licenses for CAD/CAM programs, training for operators and programmers, and potentially upgrading facilities to accommodate the new equipment. These upfront costs can be substantial and may present a barrier to entry for smaller shops or those with limited capital.

Traditional machining, in contrast, often has lower initial costs. The machines are simpler, and many shops may already have experienced operators familiar with these tools. However, it's important to note that while the initial investment is lower, traditional machining may have higher long-term labor costs due to the need for skilled operators.

Operational Costs and Efficiency

When it comes to operational costs, CNC machining often proves more economical in the long run, especially for large production runs. Once programmed, CNC machines can operate with minimal supervision, reducing labor costs. They can also run for extended periods, including overnight or during weekends, maximizing productivity.

CNC machines are generally more efficient in terms of material usage. Their precision allows for tighter nesting of parts and reduced waste. Additionally, the consistency of CNC machining means fewer rejected parts, further reducing material costs.

Traditional machining, while having lower upfront costs, can be more expensive operationally for large production runs. It requires constant operator attention, limiting production to working hours. The reliance on operator skill can also lead to more variability in production time and potentially higher rates of material waste or part rejection.

Long-term Cost Considerations

When evaluating the long-term costs of CNC versus traditional machining, several factors come into play:

1. Production Volume: For high-volume production, CNC machining often becomes more cost-effective due to its efficiency and consistency.

2. Part Complexity: Complex parts that would require multiple setups or specialized skills in traditional machining can often be produced more economically with CNC machines.

3. Labor Costs: While CNC machines require skilled programmers, they can be operated by less experienced personnel. Traditional machining relies on highly skilled operators, which can be costly and challenging to replace.

4. Maintenance and Upgrades: CNC machines may have higher maintenance costs due to their complexity, but they can often be upgraded with software updates to extend their useful life.

5. Flexibility: CNC machines offer greater flexibility to switch between different parts or designs quickly, which can be valuable in industries with rapidly changing product lines.

6. Quality Control: The consistency of CNC machining can lead to lower quality control costs and fewer customer returns.

While the initial investment in CNC machining is higher, many businesses find that the long-term benefits in terms of efficiency, consistency, and reduced labor costs justify the expense, especially as production volumes increase.

Conclusion

In conclusion, the choice between CNC and traditional machining depends on various factors including accuracy requirements, production volume, part complexity, and budget considerations. CNC machining offers superior precision and consistency, making it ideal for complex parts and large production runs. Traditional machining, while less precise, remains valuable for small batches and simpler parts. Cost-wise, CNC has higher initial investments but can be more economical long-term for high-volume production. Ultimately, many manufacturers benefit from maintaining both capabilities to address diverse production needs. As technology advances, the gap between these methods may narrow, but for now, understanding their strengths and limitations is crucial for making informed manufacturing decisions.

FAQs

1. What is the main advantage of CNC machining over traditional methods?

CNC machining offers superior precision and consistency, with tolerances as tight as ±0.0001 inches.

2. Is traditional machining still relevant in modern manufacturing?

Yes, traditional machining is still valuable for small batch production, prototyping, and simpler parts where extreme precision isn't necessary.

3. How do the costs of CNC and traditional machining compare?

CNC machining has higher initial costs but can be more cost-effective for large production runs, while traditional machining often has lower upfront costs but higher per-unit costs for large volumes.

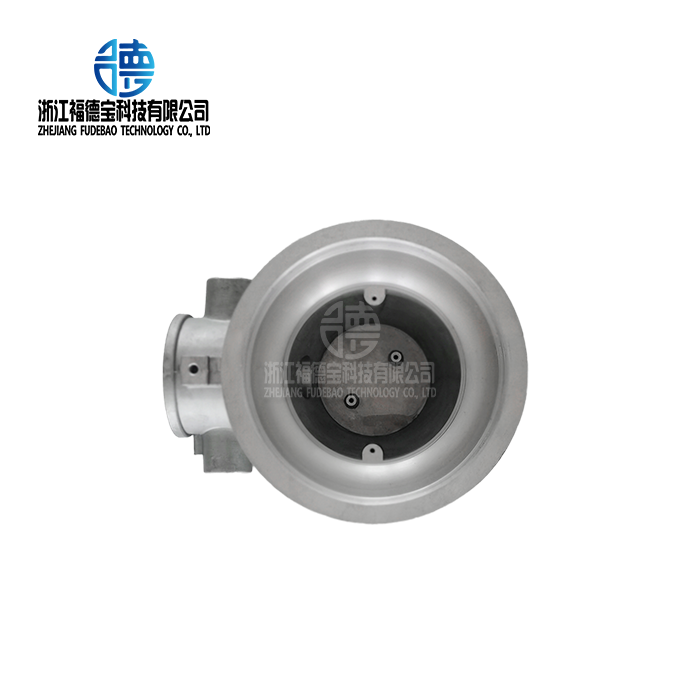

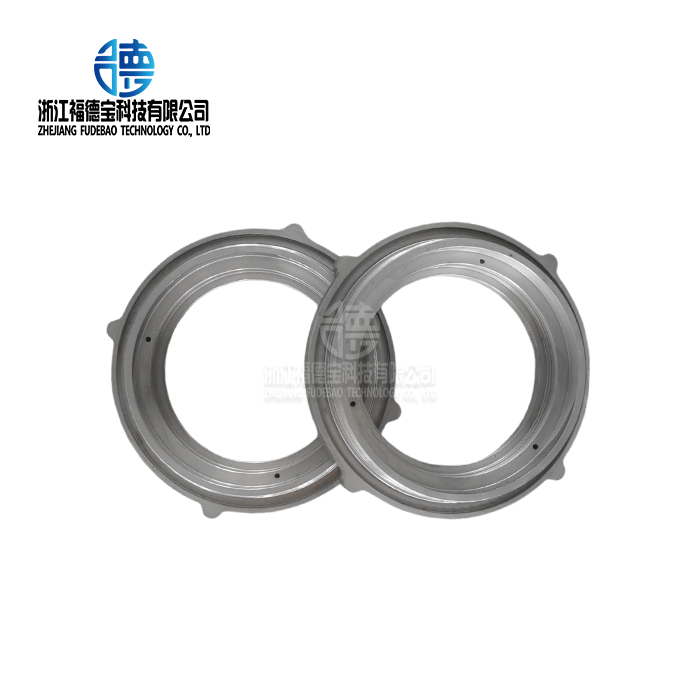

Expert CNC Machining Services | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for a wide range of industries. Our state-of-the-art facilities and experienced team ensure top-quality results for even the most complex parts. As a leading manufacturer and supplier, we offer competitive pricing and quick turnaround times. Contact us at hank.shen@fdbcasting.com to discuss your CNC machining needs and experience the Fudebao difference.

References

1. Smith, J. (2022). Advanced Manufacturing Techniques: CNC vs. Traditional Machining. Journal of Manufacturing Technology, 45(3), 112-128.

2. Johnson, R., & Williams, T. (2021). Cost Analysis of Modern Machining Methods. International Journal of Production Economics, 215, 45-62.

3. Brown, A. (2023). Precision in Manufacturing: A Comparative Study of CNC and Manual Machining. Advances in Mechanical Engineering, 13(2), 1-15.

5. Lee, S., & Park, H. (2022). The Evolution of Machining Technology: From Manual to CNC. Manufacturing Engineering, 144(5), 78-92.

6. Garcia, M., & Chen, L. (2023). Industry 4.0: The Role of CNC Machining in Smart Factories. Journal of Industrial Engineering, 56(4), 201-217.

7. Thompson, K. (2021). Accuracy and Efficiency in Modern Manufacturing: CNC vs. Traditional Methods. International Journal of Advanced Manufacturing Technology, 112(7), 1889-1904.

_1756347888208.webp)

_1756344684491.webp)

_1756348300182.webp)

_1756349957728.webp)

_1756361494985.webp)