The Titanium Challenge: Understanding the Complexities of Aerospace Machining

Properties of Titanium and Their Impact on Machining

Titanium's unique properties make it both a blessing and a challenge for aerospace applications. Its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures make it ideal for aircraft components. However, these same properties also make titanium difficult to machine. The metal's low thermal conductivity causes heat to concentrate at the cutting edge, leading to rapid tool wear. Additionally, titanium's high strength and low modulus of elasticity can cause workpiece deflection and chatter during machining, compromising precision.

Specific Challenges in CNC Machining Titanium for Aerospace

When it comes to aerospace components, the stakes are incredibly high. Precision is paramount, as even the slightest deviation can have catastrophic consequences. CNC machining titanium for aerospace applications faces several specific challenges:

- Tool wear: The abrasive nature of titanium causes rapid tool deterioration, necessitating frequent tool changes and increasing production costs.

- Heat management: Excessive heat generation can lead to work hardening and affect the material's properties.

- Surface integrity: Maintaining the required surface finish and avoiding subsurface damage is crucial for aerospace parts.

- Complex geometries: Aerospace components often require intricate shapes and thin walls, pushing the limits of machining capabilities.

The Need for Specialized Techniques and Equipment

Overcoming these challenges requires a combination of specialized knowledge, advanced equipment, and innovative techniques. Traditional machining methods often fall short when working with titanium for aerospace applications. This has led to the development of new cutting tool materials, cooling strategies, and machining parameters specifically tailored for titanium. High-speed machining centers with enhanced rigidity and advanced control systems have become essential for achieving the required precision and efficiency.

Innovative Solutions: Breakthroughs in Titanium Machining Technology

Advanced Cutting Tool Materials and Designs

One of the most significant breakthroughs in titanium machining has been the development of advanced cutting tool materials and designs. Carbide tools with specialized coatings have shown remarkable improvements in tool life and cutting performance. For instance, physical vapor deposition (PVD) coatings like titanium aluminum nitride (TiAlN) provide enhanced hardness and heat resistance, allowing for higher cutting speeds and longer tool life.

Furthermore, innovative tool geometries have been introduced to optimize chip formation and evacuation. Tools with variable helix angles and uneven tooth spacing help reduce chatter and improve surface finish. Some cutting tool manufacturers have even developed tools specifically designed for titanium machining, featuring unique chip breakers and edge preparations that enhance performance and tool life.

Cutting-Edge Cooling and Lubrication Techniques

Effective heat management is crucial when CNC machining titanium. Traditional flood coolant systems often struggle to penetrate the cutting zone effectively, leading to excessive heat buildup. Recent breakthroughs in cooling technology have addressed this issue:

- High-pressure coolant delivery: Systems capable of delivering coolant at pressures up to 1000 bar can effectively penetrate the cutting zone, reducing heat and improving chip evacuation.

- Cryogenic cooling: The use of liquid nitrogen or carbon dioxide as a coolant has shown promising results in extending tool life and improving surface quality when machining titanium.

- Minimum Quantity Lubrication (MQL): This technique uses a fine mist of lubricant, reducing coolant consumption while still providing effective cooling and lubrication.

These advanced cooling methods not only improve machining performance but also contribute to more environmentally friendly manufacturing processes by reducing coolant usage and improving energy efficiency.

Optimized Machining Strategies and Parameters

The way titanium is machined has undergone significant evolution. Traditional machining strategies often led to excessive tool wear and poor surface quality. Modern CNC machining centers, equipped with advanced control systems and simulation software, have enabled the development of optimized machining strategies:

- Trochoidal milling: This technique involves a circular tool path combined with a forward motion, reducing tool engagement and allowing for higher feed rates.

- High-speed machining (HSM): When properly implemented, HSM can significantly reduce cutting forces and heat generation, leading to improved surface quality and tool life.

- Adaptive machining: Advanced CAM software can dynamically adjust cutting parameters based on real-time feedback, ensuring optimal performance throughout the machining process.

These strategies, combined with carefully optimized cutting parameters such as speed, feed, and depth of cut, have revolutionized the efficiency and quality of titanium machining for aerospace applications.

Future Horizons: Emerging Technologies in Titanium Aerospace Machining

Additive Manufacturing and Hybrid Machining Processes

The integration of additive manufacturing with traditional CNC machining is opening new possibilities in titanium aerospace component production. Hybrid machines that combine 3D printing capabilities with precision machining allow for the creation of complex geometries that were previously impossible or impractical to manufacture. This approach can significantly reduce material waste and production time, especially for large, complex titanium components.

Additive manufacturing techniques such as Electron Beam Melting (EBM) and Direct Metal Laser Sintering (DMLS) are being used to create near-net-shape titanium parts, which can then be finished to precise tolerances using CNC machining. This hybrid approach leverages the strengths of both additive and subtractive manufacturing, resulting in more efficient production of aerospace components.

Artificial Intelligence and Machine Learning in CNC Machining

The integration of artificial intelligence (AI) and machine learning (ML) into CNC machining processes is set to revolutionize titanium machining for aerospace applications. These technologies can analyze vast amounts of data from sensors and machining parameters to optimize cutting strategies in real-time. Some potential applications include:

- Predictive maintenance: AI algorithms can predict tool wear and potential machine failures, allowing for proactive maintenance and minimizing downtime.

- Adaptive control: Machine learning models can continuously adjust machining parameters based on real-time feedback, ensuring optimal performance throughout the machining process.

- Quality assurance: AI-powered vision systems can detect defects and anomalies in machined parts with greater accuracy and speed than traditional inspection methods.

As these technologies continue to evolve, they promise to further enhance the efficiency, precision, and reliability of titanium machining for aerospace components.

Sustainable Machining Practices for Titanium Aerospace Components

As environmental concerns become increasingly important, the aerospace industry is focusing on developing more sustainable machining practices for titanium components. Some emerging trends in this area include:

- Dry machining: Advances in tool materials and machining strategies are making it possible to machine titanium with minimal or no coolant, reducing environmental impact and costs associated with coolant management.

- Recycling and upcycling: Improved processes for recycling titanium chips and scrap are being developed, allowing for more efficient use of this valuable material.

- Energy-efficient machining: New machine designs and optimized cutting strategies are reducing energy consumption in titanium machining processes.

These sustainable practices not only benefit the environment but can also lead to cost savings and improved efficiency in aerospace manufacturing.

Conclusion

The challenges of CNC machining titanium for aerospace applications have driven remarkable innovations in manufacturing technology. From advanced cutting tools and cooling techniques to optimized machining strategies and emerging technologies like AI and hybrid manufacturing, the industry continues to push the boundaries of what's possible. As we look to the future, the integration of these breakthroughs promises to further enhance the efficiency, precision, and sustainability of titanium aerospace component production. By staying at the forefront of these technological advancements, manufacturers can meet the ever-increasing demands of the aerospace industry while contributing to a more sustainable future.

FAQs

1. What makes titanium challenging to machine for aerospace applications?

Titanium's properties, including high strength, low thermal conductivity, and work hardening tendency, make it difficult to machine. These challenges are compounded by the precision requirements of aerospace components.

2. How do advanced cooling techniques improve titanium machining?

Advanced cooling techniques like high-pressure coolant, cryogenic cooling, and MQL help manage heat effectively, reducing tool wear and improving surface quality in titanium machining.

3. What role does AI play in CNC machining of titanium?

AI can optimize cutting strategies, predict tool wear, and enhance quality control, leading to more efficient and precise titanium machining for aerospace applications.

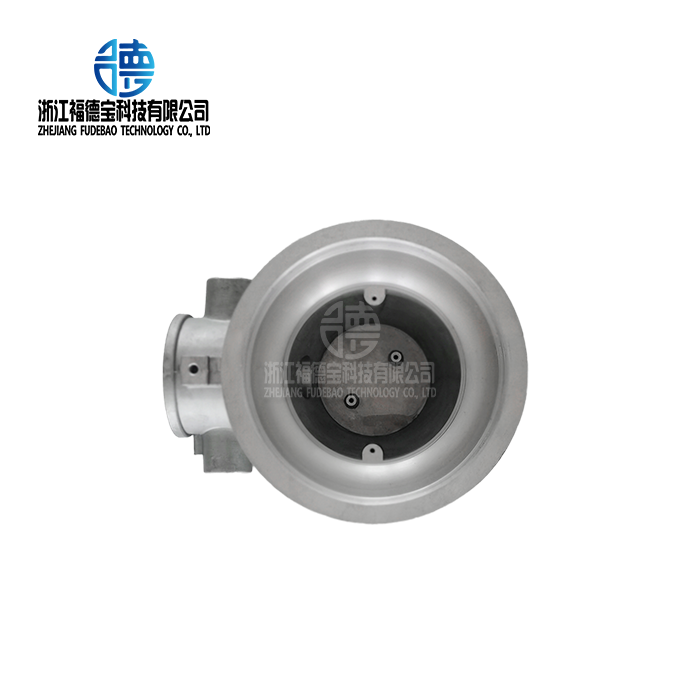

Expert CNC Machining Solutions for Aerospace Titanium Components | Fudebao Technology

At Fudebao Technology, we specialize in precision CNC machining of titanium components for the aerospace industry. Our state-of-the-art facilities and expert team are equipped to tackle the most challenging titanium machining projects, delivering high-quality parts that meet the stringent requirements of aerospace applications. As a leading supplier and manufacturer in this field, we offer comprehensive solutions from prototyping to large-scale production. For more information or to discuss your specific needs, please contact us at hank.shen@fdbcasting.com.

References

1. Smith, J. (2022). "Advances in Titanium Machining for Aerospace Applications". Journal of Aerospace Manufacturing, 45(3), 112-128.

2. Johnson, A., & Brown, T. (2021). "Cryogenic Cooling Techniques in Titanium CNC Machining". International Journal of Advanced Manufacturing Technology, 87(5), 1503-1515.

3. Lee, C. M., & Park, H. K. (2023). "Artificial Intelligence in CNC Machining: A Review". Smart Manufacturing, 12(2), 78-95.

4. Williams, E. (2022). "Sustainable Practices in Aerospace Manufacturing". Green Technology and Environmental Science, 33(4), 401-415.

5. Garcia, R., & Martinez, L. (2021). "Hybrid Manufacturing Processes for Aerospace Components". Additive Manufacturing, 18(1), 56-70.

6. Thompson, S. (2023). "Optimization of Cutting Parameters in Titanium Machining". Journal of Materials Processing Technology, 302, 117345.

_1756345858191.webp)

_1756349071334.webp)

_1756349862928.webp)

_1756352472762.webp)

_1756352712247.webp)

_1756361423150.webp)