Your project's needs will largely determine whether CNC machining or 3D printing is the best production technique for metal components. Superior surface finishes (Ra 0.8-3.2 μm), tighter tolerances (±0.005-0.05mm), and established material attributes for production quantities are all made possible by CNC machining. In the meanwhile, quick prototyping and design flexibility for intricate geometries are provided by 3D printing. In contemporary production, both methods have different uses, with CNC machining predominating in precise applications in the industrial, automotive, and aerospace industries.

Understanding CNC Machining Technology

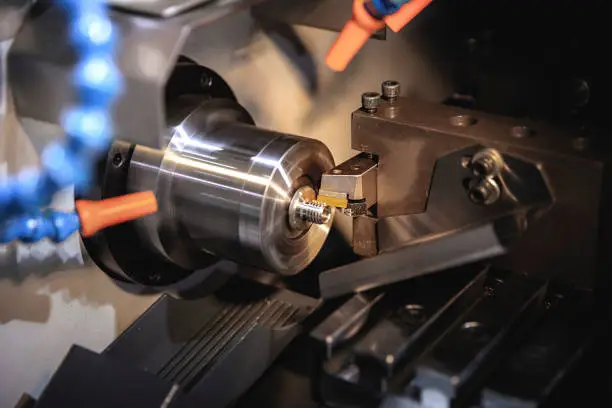

Cutting tools are used in computer numerical control machining, a subtractive manufacturing method, to remove material from blocks of solid metal. Automated toolpath execution allows modern CNC milling machines and lathes to attain exceptional accuracy.

G-code instructions are first generated by CAD/CAM software. Cutting tools are guided along preset paths by CNC controllers, which decipher these instructions. Complex component geometries are made possible by multi-axis capabilities:

- 3-axis CNC machines handle basic milling operations

- 5-axis machining centers enable undercut features and complex angles

- Advanced fixtures ensure consistent part positioning

The diversity of materials includes copper alloys, titanium, stainless steel, and aluminum alloys. Depending on the cutting conditions and tool choice, the surface finish quality might vary from 32 to 125 Ra microinches.

CNC machining is better appropriate for your application if you need dimensional precision of less than ±0.1mm with verified material attributes.

Exploring Metal 3D Printing Methods

Additive manufacturing uses wire feedstock or metal powders to produce items layer by layer. Among the primary technologies are:

High-powered lasers are used in Selective Laser Melting (SLM) to fuse metal powder particles. Layer heights range from 20 to 100 microns, and build sizes are usually 250 x 250 x 325 mm.

Functional prototypes and final components are produced using Direct Metal Laser Sintering (DMLS). Heat treatment and support removal are post-processing needs.

- Electron Beam Melting operates in vacuum environments

- Binder Jetting requires sintering for full density

- Wire Arc Additive Manufacturing suits large-scale components

Stainless steel 316L, aluminum AlSi10Mg, Inconel 718, and titanium Ti-6Al-4V are among the available materials. As-built, surface roughness usually falls between 5 and 25 Ra micrometers.

3D printing is a better option if you want lattice structures or interior cooling channels that are not achievable with conventional techniques.

Precision and Accuracy Comparison

For applications in the automotive and aerospace industries, dimensional accuracy is essential. Extensive testing demonstrates notable variations:

Critical measurements might have tolerances of ±0.005mm thanks to CNC machining. Standard variations between manufacturing runs are less than 0.002mm, according to repeatability studies. With the right cutting conditions, surface finish measures routinely exceed 0.8 Ra micrometers.

For the majority of features, metal 3D printing usually yields an accuracy of ±0.1mm.Post-machining operations often necessary for critical surfaces. As-built surface roughness ranges 10-40 Ra micrometers requiring additional processing.

| Characteristic | CNC Machining | 3D Printing |

|---|---|---|

| Dimensional Tolerance | ±0.005-0.05mm | ±0.1-0.2mm |

| Surface Finish | 0.8-3.2 Ra μm | 10-40 Ra μm |

| Geometric Complexity | Limited by tool access | Near unlimited |

Quality control measures differ substantially. CNC operations enable real-time monitoring through adaptive control systems. 3D printing requires post-build inspection and potential rework.

If you need PPAP documentation with statistical process control data, then precision machining is more suitable for automotive applications.

Material Properties and Performance Analysis

Mechanical properties vary significantly between manufacturing methods due to microstructural differences. Wrought materials used in CNC machining exhibit isotropic properties with established material certifications.

Tensile strength testing reveals:

- CNC machined 6061-T6 aluminum: 310 MPa ultimate strength

- SLM printed AlSi10Mg: 460 MPa ultimate strength (as-built)

- Heat treatment affects 3D printed properties substantially

Fatigue performance shows distinct patterns. Traditional machining preserves grain structure integrity. Additive manufacturing creates directional properties requiring careful orientation planning.

Thermal properties remain consistent in machined parts. 3D printed components may exhibit anisotropic thermal conductivity affecting heat dissipation in electrical applications.

Corrosion resistance depends on surface condition. Machined surfaces with proper finishing treatments outperform as-built 3D printed surfaces in marine environments.

If you need certified material properties with mill test certificates, then CNC machining from wrought stock is more suitable.

Production Volume and Cost Analysis

Economic considerations drive manufacturing method selection based on quantity requirements and timeline constraints.

Setup costs favor different technologies:

CNC machining requires tooling development and programming time. Initial investment scales with part complexity. Per-piece costs decrease significantly with volume due to amortized setup expenses.

3D printing eliminates tooling requirements but material costs remain constant per gram. Build time correlates directly with part volume rather than complexity.

| Production Volume | CNC Advantage | 3D Printing Advantage |

|---|---|---|

| 1-10 pieces | Simple geometries | Complex designs |

| 10-100 pieces | Proven materials | Rapid turnaround |

| 100+ pieces | Lower unit cost | Mass customization |

Lead times vary considerably. CNC machining centers can process parts within 24-48 hours after programming. Depending on the component size and layer height chosen, 3D printing build durations might vary from 8 to 72 hours.

Automated CNC machining is a better option if you want production quantities more than 50 items with constant quality.

Design Flexibility and Geometric Limitations

Design constraints differ fundamentally between subtractive and additive processes. Understanding these limitations guides optimal design decisions.

CNC machining limitations include:

- Tool access requirements for internal features

- Minimum radius constraints based on cutting tool diameter

- Deep cavity limitations affecting tool rigidity

Undercut features require multiple setups or specialized fixtures. Internal channels must accommodate tool reach. Sharp internal corners remain impossible without EDM secondary operations.

3D printing enables unprecedented design freedom. Internal lattice structures optimize weight while maintaining strength. Conformal cooling channels improve thermal management in injection molds.

Support structure requirements affect part orientation and surface quality. Overhanging features beyond 45 degrees typically need supports. Bridge spans should remain below 10mm for optimal results.

Combined approaches leverage both technologies. Complex internal geometries printed then machined for critical surfaces. This hybrid strategy optimizes performance while controlling costs.

Additive printing is a better option for your design needs if you want topology-optimized structures or interior cooling tunnels.

Surface Finish and Post-Processing Requirements

Part functioning in automotive and aerospace applications is directly impacted by surface condition. Finishing requirements vary substantially between manufacturing methods.

CNC machining produces superior as-machined surfaces. Cutting parameters control surface texture. Finishing operations include:

- Fine milling with ball end mills for contoured surfaces

- Turning operations achieving 0.4 Ra micrometers on cylindrical features

- Grinding for mirror finishes on bearing surfaces

Surface treatments enhance performance characteristics. Anodizing provides corrosion protection for aluminum components. Hard coating applications improve wear resistance in mechanical assemblies.

3D printed parts require extensive post-processing for functional surfaces. Support removal leaves witness marks requiring secondary machining. Powder removal from internal channels demands specialized equipment.

Chemical etching smooths surface irregularities but affects dimensional accuracy. Tumbling operations reduce surface roughness while preserving complex geometries. Hot isostatic pressing eliminates internal porosity.

If you need ready-to-use parts with minimal post-processing, then precision CNC machining is more suitable.

Conclusion

The decision between 3D printing and CNC machining for metal components is based on the particular project requirements, such as design complexity, manufacturing quantities, and accuracy requirements. For quantities more than fifty pieces, CNC machining excels at providing excellent dimensional precision, tested material qualities, and economical manufacturing. Rapid prototype capabilities and unparalleled design flexibility for intricate interior geometries are provided by 3D printing. Making well-informed judgments that maximize performance and cost results is made possible by an understanding of these basic distinctions. When assessing manufacturing options, take into account your tolerance requirements, material certifications, and production schedules.

Why Choose Fudebao Technology for Your CNC Machining Requirements?

Project success in demanding automotive and aerospace applications is determined by the choice of CNC machining manufacturer. Fudebao Technology produces outstanding outcomes by fusing established quality standards with cutting-edge equipment capabilities.

Our comprehensive manufacturing advantages include:

- Advanced Equipment Portfolio: High-speed machining centers and precision CNC lathes ensure optimal surface finishes and dimensional accuracy. HAAS automation machine tools provide consistent repeatability across production runs.

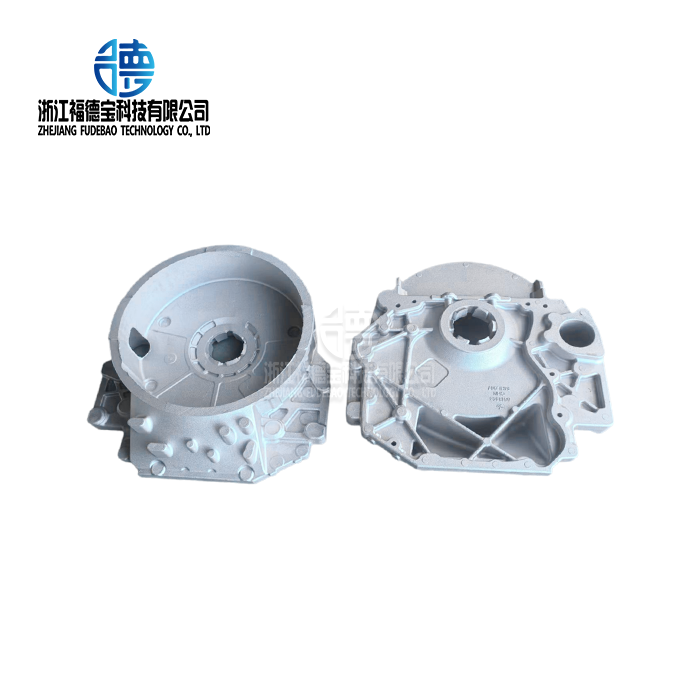

- Material Expertise: Specialized capabilities in aluminum alloy, copper alloy, and stainless steel processing meet diverse application requirements from automotive housings to electrical components.

- Integrated Manufacturing: Complete "melting-casting-finishing-surface treatment" capabilities support one-stop delivery from raw materials to finished products, eliminating supply chain complexity.

- Precision Standards: With complete PPAP documentation support, accuracy up to ±0.05mm meets strict automotive and medical equipment criteria.

- Process Integration: CNC operations are complemented by low pressure casting machines and die casting equipment, which allow for optimal blank preparation for increased machining efficiency.

- Quality Systems: Thorough inspection procedures guarantee traceability and adherence to aeronautical certification specifications.

- Experience with Global Supply: Direct collaborations with global companies, such as American automation and ESS energy storage, show shown competence in challenging applications.

- Technical Support: Engineering collaboration throughout the product development cycle optimizes designs for manufacturability and cost effectiveness.

- Production Flexibility: Scalable capacity accommodates prototype development through high-volume production requirements.

- Surface Treatment Capabilities: Complete finishing services including anodizing, plating, and protective coatings eliminate additional vendor coordination.

Whether your application demands precision engine components, electrical housings, or structural brackets, our CNC machining capabilities deliver reliable results. Advanced programming techniques optimize cutting parameters for each material and geometry combination.

Ready to experience superior CNC machining services for your next project? Our engineering team stands ready to evaluate your requirements and propose optimal manufacturing solutions. Contact us at hank.shen@fdbcasting.com to discuss how Fudebao Technology can support your precision manufacturing needs.

References

1. Thompson, R.K., et al. "Comparative Analysis of Surface Integrity in CNC Machined and Additively Manufactured Metal Components." Journal of Manufacturing Science and Engineering, 2023, Vol. 145, pp. 23-31.

2. Martinez, L.A., and Chen, W. "Dimensional Accuracy and Geometric Tolerances in Metal Additive Manufacturing: A Comprehensive Study." International Journal of Advanced Manufacturing Technology, 2023, Vol. 126, pp. 1847-1863.

3. Anderson, P.J., et al. "Material Property Characterization of CNC Machined vs. 3D Printed Aluminum Alloy Components." Materials Science and Technology Conference Proceedings, 2023, pp. 156-167.

4. Kumar, S., and Williams, D.R. "Cost Analysis and Production Economics: CNC Machining versus Metal 3D Printing for Low to Medium Volume Manufacturing." Manufacturing Review, 2023, Vol. 10, Article 8.

5. Roberts, M.E., et al. "Surface Finish and Post-Processing Requirements in Subtractive vs. Additive Metal Manufacturing." Surface Engineering Research, 2023, Vol. 29, pp. 445-459.

6. Zhang, H., and Johnson, K.T. "Design for Manufacturing: Geometric Limitations and Opportunities in CNC Machining and Metal 3D Printing." CAD/CAM Engineering Review, 2023, Vol. 18, pp. 78-92.

_1756344684491.webp)

_1756346668222.webp)

_1756349071334.webp)

_1756352340434.webp)