CNC machining uses computer-controlled production procedures to convert digital designs into precise components. From initial CAD models to final products, this thorough book takes you through every step of the production process. Engineers, sourcing directors, and procurement teams may make well-informed judgments on component manufacture by having a thorough understanding of the whole process. In order to guarantee that dimensional accuracy and surface finish standards satisfy industry requirements, the process includes CAD/CAM programming, material selection, toolpath optimization, and quality control procedures.

Understanding the CNC Manufacturing Process

Computer-aided design (CAD) software is the first step in the process of turning a digital notion into a physical component. Engineers produce intricate 3D models that specify each final part's dimensions, surface, and geometric characteristics. All ensuing production processes are built on top of these models.

The gap between machine execution and design intent is filled by CAD/CAM software. After analyzing the three-dimensional geometry, the system creates toolpaths that precisely direct cutting instruments. In order to maximize production efficiency, this method takes into account the characteristics of the material, the specifications of the cutting tool, and the capabilities of the machining center.

G-code instructions, which specify every facet of the machining process, are interpreted by contemporary CNC controllers. In accordance with preset specifications, feed rates, spindle speeds, and tool changes happen automatically. This automation reduces human mistake while guaranteeing consistent outcomes across manufacturing runs.

The choice of material is essential when deciding on machining techniques. Stainless steel and copper alloys need different cutting settings than aluminum alloys. Aerospace applications need materials with remarkable strength-to-weight ratios, whereas automotive components often use lightweight aluminum for structural elements and engine parts.

Essential CAD/CAM Programming Fundamentals

A thorough grasp of both design specifications and production limitations is necessary for efficient CAD/CAM programming. During the programming stage, engineers have to take workholding techniques, machining sequences, and tool accessibility into account. Production delays and expensive redesigns are avoided by this forethought.

In CNC machining, toolpath creation entails intricate computations that maximize cutting effectiveness while preserving surface quality. While 5-axis machining allows for complicated geometries used in automotive and aerospace applications, 3-axis machining manages the majority of standard processes. Cutting tools can approach workpieces from numerous angles thanks to the extra rotating axes, which lowers setup needs and increases accuracy.

Toolpaths are verified by CNC simulation software prior to the start of real machining. Virtual machining calculates cycle durations, confirms surface finishes, and detects possible collisions. In addition to guaranteeing that dimensional standards can be met, this verification step guards against costly tool breakage and workpiece damage.

diverse industries use quite diverse programming methodologies. Whereas aerospace manufacturers prioritize traceability and certification requirements, automotive suppliers concentrate on high-volume manufacturing using repeatable procedures. Applications for industrial equipment often need flexible batch manufacturing capabilities to handle different order amounts.

Material Selection and Preparation Strategies

The performance of the finished component and the success of the machining process are directly impacted by the choice of materials. Because of their superior machinability and resistance to corrosion, aluminum alloys are widely used in automotive applications. These materials are perfect for precision parts like brackets and housings since they machine cleanly and need little work hardening.

In electrical applications where conductivity and heat control are critical, copper alloys perform very well. Copper castings are used by producers of power equipment for electrical housings and motor components. Applications for medical devices also benefit from the material's inherent antibacterial qualities.

In demanding working conditions, stainless steel offers exceptional resistance to corrosion. Stainless steel is often needed for parts of industrial equipment that are subjected to chemicals or high temperatures. When using the right cutting tools and coolant techniques, the material machines well.

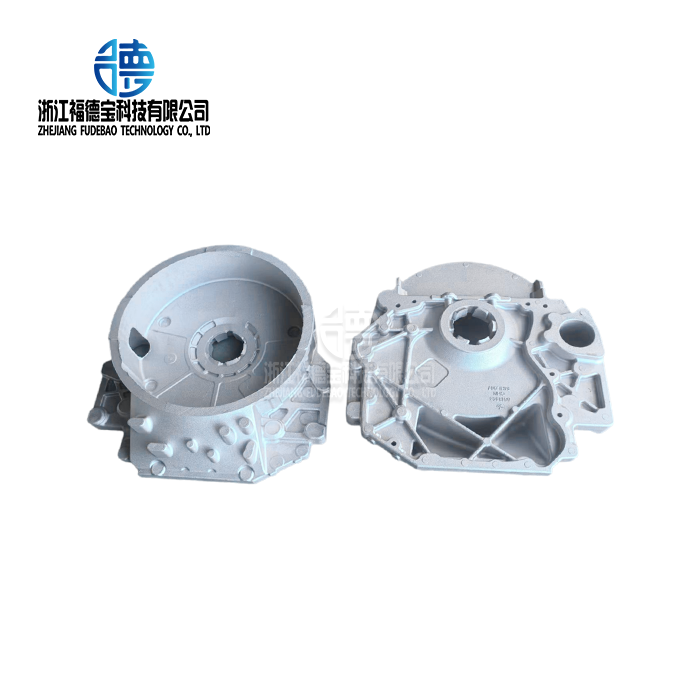

The preparation of raw materials has a big impact on the results of machining. Die-cast components need different methods than sand-cast blanks. When compared to gravity casting techniques, low-pressure casting yields better material density and mechanical qualities. Material properties may be changed by heat treatment procedures to improve final component performance or machinability.

CNC Machine Types and Capabilities

The foundation of contemporary precision production is represented by machining centers. These multipurpose devices integrate tapping, drilling, and milling functions into a single configuration. Automated tool changes improve uniformity and save labor costs by enabling complicated components to be finished without human intervention.

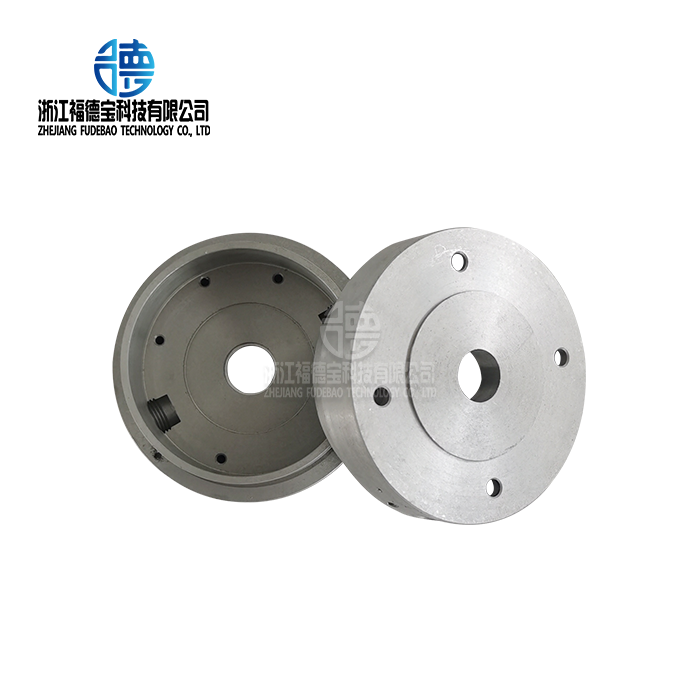

Shafts, flanges, and cylindrical housings are among the rotating components that CNC lathes specialize in. On circular features, turning processes provide precise tolerances and superb surface finishes. The ability of multi-axis lathes to do milling operations increases their capacity for intricate designs.

High-speed machining facilities are excellent at complex details and thin-wall components. High-speed capabilities that provide improved surface finishes while maintaining dimensional stability are advantageous for automobile housings and aerospace brackets. Workpiece deformation during machining is minimized by lower cutting forces.

Larger parts and sheet materials are readily handled by CNC routers. When material removal rates are more crucial than ultra-precision tolerances, these machines perform very well on automobile panels and structural components. For high-volume manufacturing, router applications often interface with automated material handling systems.

Precision Engineering and Quality Control

Thermal effects, tool wear, and machine dynamics must all be carefully considered in order to achieve dimensional precision. Variations in temperature have the potential to significantly alter the dimensions of precision components. Repeatability within tolerances of ±0.05mm is made possible by climate-controlled production settings, which maintain constant conditions.

In CNC machining, the choice of cutting tool has a direct impact on dimensional accuracy and surface finish quality. While diamond-coated tools provide great surface finishes on aluminum components, carbide tools offer exceptional wear resistance for industrial applications. Systems for monitoring tool life keep tabs on wear trends and forecast when to replace them.

Throughout the production process, sophisticated measuring devices confirm the size of the components. Coordinate measurement machines (CMMs) provide thorough inspection capabilities that record adherence to technical requirements. Trends are found via statistical process control before they have an impact on the quality of the final output.

Extensive quality records are required for PPAP documentation in automotive applications. Over long manufacturing runs, each component must exhibit dimensional compliance and process capabilities. To guarantee traceability, certification systems monitor inspection outcomes, process parameters, and material certifications.

Surface Treatment and Finishing Operations

Surface treatments improve component performance in ways that are not possible with machining alone. For aluminum components, anodizing offers superior corrosion protection while preserving dimensional precision. In demanding applications, the procedure prolongs component life by producing a strong, wear-resistant surface.

Material characteristics are altered by heat treatment procedures to satisfy certain performance standards. Internal pressures that may eventually result in dimensional instability are lessened by stress relief. While preserving machinability after early processing, age hardening improves strength attributes.

Applications for coatings provide specific surface characteristics for certain working circumstances. While thermal barrier coatings shield components from very high or low temperatures, anti-friction coatings reduce wear in sliding applications. Coatings with electrical conductivity improve power transmission applications.

Measurements of surface finish quantify textural properties that influence component performance. While more sophisticated measures record peak heights and valley depths, Ra values define average roughness characteristics. Certain surface textures are often needed for automotive sealing surfaces in order to guarantee optimal gasket function.

Industry-Specific Applications and Standards

High-volume production capabilities with reliable quality results are necessary for the automotive industry. Under situations of heat cycling, engine components need to have excellent dimensional stability. Over long service intervals, transmission housings must have exact bearing fittings.

CNC machining is used in aerospace applications to reduce weight without sacrificing structural integrity. 5-axis machining skills are often needed for complex designs in order to reduce the number of parts and assembly needs. Strict adherence to safety regulations is guaranteed by process documentation and material certifications.

Manufacturers of industrial equipment place a high importance on adaptable manufacturing capabilities that can handle different batch sizes. Compressor parts and pump housings need strong materials that can resist corrosive conditions and high pressures. In situations where operating temperatures are high, heat resistance becomes crucial.

Surface conductivity and dimensional precision are key factors in electrical equipment applications. Motor housings must provide heat dissipation pathways and magnetic assemblies with exact fittings. Tight tolerances are necessary for connector components to provide dependable electrical connections throughout a long service life.

Conclusion

Partner with Fudebao Technology for Expert CNC Machining

Comprehensive precision manufacturing solutions are provided by Zhejiang Fudebao Technology Co., Ltd., which turns your concepts into premium parts. Our cutting-edge facility allows for seamless manufacturing from raw materials to completed components by combining cutting-edge machining centers, CNC lathes, and casting capabilities under one roof.

We have experience treating stainless steel, copper alloy, and aluminum alloy for use in electrical, industrial, automotive, and aerospace applications. Our dimensional accuracy is up to ±0.05mm, and we provide flexible batch manufacturing that may be tailored to your unique needs. Industry standards compliance is guaranteed by PPAP certification and documentation systems.

Lead times are shortened and multiple vendor coordination is eliminated across the whole production process, from melting to surface treatment. Together with your design experts, our skilled engineering team optimizes components for manufacturing without sacrificing performance requirements.

Are you prepared to use precise CNC machining to revolutionize your next project? Reach out to our CNC machining supply team at hank.shen@fdbcasting.com to talk about your unique needs. For your component production requirements, we provide affordable quotes and thorough capacity evaluations.

References

1. Smith, J.A. (2023). Advanced CNC Programming Techniques for Precision Manufacturing. Industrial Manufacturing Press, 3rd Edition.

2. Chen, L.M. & Rodriguez, P.K. (2022). Material Science in Modern Machining Operations. Engineering Materials Journal, Volume 45, Issue 8.

3. Thompson, R.W. (2024). Quality Control Systems in Automotive Component Manufacturing. Precision Engineering Quarterly, Volume 31, Issue 2.

4. Anderson, M.J. & Kim, S.H. (2023). Surface Treatment Technologies for Machined Components. Manufacturing Technology Review, Volume 18, Issue 5.

5. Williams, D.C. (2022). CAD/CAM Integration Strategies for Complex Geometries. Computer-Aided Manufacturing Today, Volume 29, Issue 11.

6. Brown, K.L. & Taylor, A.R. (2024). Industry 4.0 Applications in CNC Manufacturing Systems. Automation Engineering International, Volume 42, Issue 3.

_1756346421748.webp)

_1756349862928.webp)