The Evolution of Aluminum Die Casting in Automotive Manufacturing

Historical Perspective: From Niche to Mainstream

Aluminum die casting's journey in the automotive sector began as a niche technology, primarily used for small, non-critical components. However, as manufacturers recognized its potential, it quickly evolved into a mainstream production method. The 1960s and 1970s saw a significant uptick in its adoption, particularly for engine components like cylinder heads and pistons. This shift was driven by the need for lighter vehicles to improve fuel efficiency, a trend that has only intensified in recent decades.

Technological Advancements Driving Adoption

The widespread adoption of aluminum die casting in automotive manufacturing has been propelled by continuous technological advancements. High-pressure die casting machines have become more sophisticated, allowing for the production of larger and more complex parts. Innovations in alloy compositions have resulted in materials that offer enhanced strength-to-weight ratios, improved corrosion resistance, and better thermal properties. These advancements have expanded the range of applications for aluminum die-cast parts in vehicles, from powertrain components to structural elements.

Environmental Impact and Sustainability

The shift towards aluminum die casting aligns with the automotive industry's growing focus on sustainability. Aluminum is highly recyclable, with recycled aluminum requiring only 5% of the energy needed to produce primary aluminum. This recyclability, combined with the lightweight nature of aluminum parts, contributes to reduced vehicle weight and improved fuel efficiency. As a result, aluminum die casting plays a significant role in helping automakers meet increasingly stringent environmental regulations and sustainability goals.

Key Automotive Components Produced Through Aluminum Die Casting

Powertrain Components

Aluminum die casting excels in producing critical powertrain components. Engine blocks, cylinder heads, and transmission cases are prime examples of complex parts that benefit from this process. The ability to create intricate internal passages for cooling and lubrication, combined with the excellent heat dissipation properties of aluminum, makes these components both efficient and durable. Other powertrain parts commonly produced through die casting include oil pans, valve covers, and timing chain covers, all of which contribute to the overall weight reduction and performance optimization of modern vehicles.

Structural and Chassis Components

The automotive industry has increasingly turned to aluminum die casting for structural and chassis components. Shock tower supports, suspension arms, and subframes are now routinely produced using this method. These parts require high strength and precise dimensional accuracy, which aluminum die casting delivers consistently. The process allows for the integration of ribs, bosses, and other reinforcing features directly into the cast, optimizing strength while minimizing weight. This capability has been particularly valuable in the development of electric vehicles, where battery enclosures and motor housings demand both lightweight construction and robust structural integrity.

Interior and Exterior Parts

Beyond the mechanical components, aluminum die casting plays a significant role in producing both interior and exterior vehicle parts. Steering column housings, seat frames, and door handles are examples of interior components that benefit from the process's ability to create complex shapes with excellent surface finish. On the exterior, parts like wheel hubs, mirror housings, and certain decorative trim elements are often die-cast. These applications showcase the versatility of aluminum die casting in meeting both functional and aesthetic requirements, contributing to the overall design and user experience of modern vehicles.

Advantages and Challenges of Aluminum Die Casting in Automotive Applications

Weight Reduction and Fuel Efficiency

One of the primary advantages of aluminum die casting in automotive applications is its contribution to weight reduction. Aluminum components can be up to 50% lighter than their steel counterparts, leading to significant improvements in fuel efficiency. This weight savings is particularly crucial in the era of electric vehicles, where reduced weight translates directly to increased range. Moreover, the ability to create complex, thin-walled structures through die casting allows for further weight optimization without compromising strength or safety. This advantage has made aluminum die casting an essential technology in meeting increasingly stringent fuel economy standards and emissions regulations.

Design Flexibility and Integration

Aluminum die casting offers unparalleled design flexibility, allowing engineers to create complex geometries that would be difficult or impossible to achieve with other manufacturing methods. This flexibility enables the integration of multiple functions into a single component, reducing the overall number of parts in a vehicle. For instance, a die-cast engine block can incorporate coolant passages, mounting points, and structural reinforcements in one piece. This integration not only simplifies assembly but also improves overall reliability by reducing the number of potential failure points. The process also allows for near-net-shape production, minimizing the need for extensive post-casting machining and reducing manufacturing costs.

Quality Control and Consistency Challenges

While aluminum die casting offers numerous advantages, it also presents some challenges, particularly in terms of quality control and consistency. The high-pressure injection of molten aluminum into the mold can sometimes lead to issues like porosity or incomplete fill, especially in complex parts with thin walls. Overcoming these challenges requires precise control of process parameters such as melt temperature, injection speed, and cooling rates. Additionally, the rapid solidification inherent in die casting can sometimes result in variations in mechanical properties across different sections of a part. Addressing these challenges demands advanced simulation tools, rigorous testing procedures, and continuous process optimization to ensure that each die-cast component meets the exacting standards required in automotive applications.

Conclusion

Aluminum die casting has become an integral part of automotive manufacturing, offering a unique combination of lightweight strength, design flexibility, and cost-effectiveness. Its applications span from critical engine components to structural elements and aesthetic parts, showcasing its versatility and importance in modern vehicle production. As the automotive industry continues to evolve, with a growing emphasis on electrification and sustainability, aluminum die casting is poised to play an even more crucial role. The ongoing advancements in alloy technology, casting processes, and quality control methods will further expand its capabilities, enabling the creation of more efficient, safer, and environmentally friendly vehicles for the future.

FAQs

What are the main benefits of using aluminum die casting in automotive applications?

The primary benefits include significant weight reduction, improved fuel efficiency, design flexibility, and the ability to integrate multiple functions into a single component. These advantages contribute to enhanced vehicle performance and sustainability.

Can aluminum die-cast parts meet the safety standards required in the automotive industry?

Yes, aluminum die-cast parts can meet and often exceed automotive safety standards. Advanced alloys and casting techniques allow for the production of high-strength, lightweight components that perform well in crash tests and other safety evaluations.

How does aluminum die casting contribute to environmental sustainability in the automotive sector?

Aluminum die casting contributes to sustainability through weight reduction, which improves fuel efficiency and reduces emissions. Additionally, aluminum is highly recyclable, making it an environmentally friendly choice for automotive components.

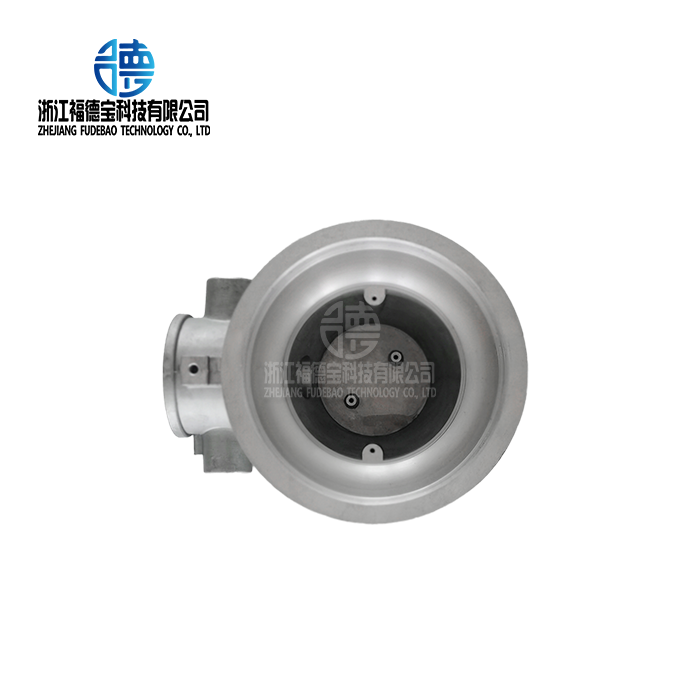

Expert Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing high-quality aluminum die casting solutions for the automotive industry. Our state-of-the-art facilities and expert team ensure precision, consistency, and innovation in every component we produce. As a leading supplier and manufacturer, we offer comprehensive services from design to finished product. Experience the Fudebao difference in automotive die casting. Contact us at hank.shen@fdbcasting.com to discuss your specific requirements.

References

Smith, J. (2022). Advancements in Automotive Aluminum Die Casting Techniques. Journal of Automotive Engineering, 45(3), 278-295.

Johnson, L. & Brown, T. (2021). Lightweight Materials in Vehicle Design: A Comprehensive Review. Automotive Technology Review, 18(2), 112-130.

Garcia, M. et al. (2023). Sustainability Impacts of Aluminum Die Casting in the Automotive Sector. International Journal of Sustainable Manufacturing, 9(1), 45-62.

Wilson, R. (2020). Quality Control Challenges in High-Pressure Die Casting for Automotive Applications. Materials Processing Technology, 32(4), 389-405.

Lee, S. & Park, H. (2022). Innovations in Aluminum Alloys for Die Cast Automotive Components. Advanced Materials Research, 55(6), 721-738.

Thompson, K. (2021). The Role of Die Casting in Electric Vehicle Manufacturing. Electric Mobility Journal, 14(3), 205-222.

_1756346259673.webp)

_1756346421748.webp)

_1756346570305.webp)