A Guide to Dimensional Tolerance Control in Sand Casting

2025-11-19

Dimensional tolerance control in sand casting is a critical aspect of the manufacturing process that ensures the production of high-quality, precision metal components. This comprehensive guide explores the key factors, techniques, and best practices for achieving optimal dimensional accuracy in sand casting operations. By understanding and implementing effective tolerance control measures, manufacturers can minimize defects, reduce scrap rates, and meet the stringent requirements of industries such as automotive, aerospace, and industrial equipment. From mold design and material selection to process monitoring and quality control, this guide covers the essential elements needed to master dimensional tolerance control in sand casting.

Understanding Dimensional Tolerance in Sand Casting

Defining Dimensional Tolerance

Dimensional tolerance in sand casting refers to the acceptable range of variation in the size, shape, and position of cast components. It is a crucial factor in ensuring that parts meet the specified requirements and function properly in their intended applications. Tolerances are typically expressed as a plus or minus deviation from the nominal dimension, such as ±0.5mm.

Understanding dimensional tolerance is essential for both manufacturers and customers. For manufacturers, it guides the production process and quality control measures. For customers, it helps in determining whether a part will fit and function correctly in their assembly or system.

Importance of Tolerance Control

Effective tolerance control in sand casting is vital for several reasons:

- Quality Assurance: Ensures that cast parts meet the required specifications and perform as intended.

- Cost Reduction: Minimizes scrap rates and rework, leading to improved efficiency and reduced production costs.

- Customer Satisfaction: Delivers consistent, high-quality parts that meet or exceed customer expectations.

- Competitive Advantage: Demonstrates manufacturing capability and precision, setting a company apart in the market.

By implementing robust tolerance control measures, foundries can enhance their reputation and secure long-term partnerships with demanding industries.

Factors Affecting Dimensional Accuracy

Several factors influence the dimensional accuracy of sand cast parts:

- Pattern Design: The accuracy and quality of the pattern directly impact the final dimensions of the cast part.

- Sand Properties: The grain size, moisture content, and compaction of the sand affect mold stability and dimensional accuracy.

- Pouring Temperature: Proper control of metal temperature during pouring is crucial for achieving consistent shrinkage rates.

- Solidification Rate: The rate at which the metal solidifies affects the final dimensions and internal structure of the casting.

- Mold Assembly: Proper alignment and securing of mold halves are essential for maintaining dimensional accuracy.

Understanding these factors allows foundries to implement targeted strategies for improving dimensional tolerance control.

Techniques for Improving Dimensional Tolerance in Sand Casting

Advanced Pattern Design and Manufacturing

Implementing advanced pattern design and manufacturing techniques is crucial for achieving tight dimensional tolerances in sand casting. Modern CAD/CAM systems enable precise pattern creation, considering factors such as shrinkage allowances and draft angles. 3D printing technology has revolutionized pattern making, allowing for rapid prototyping and iterative design improvements.

Key considerations in pattern design include:

- Incorporating proper draft angles to facilitate easy removal of the pattern from the sand mold

- Designing adequate fillets and radii to reduce stress concentrations and improve castability

- Optimizing gating and risering systems to ensure proper metal flow and solidification

By leveraging these advanced techniques, foundries can significantly enhance the dimensional accuracy of their sand cast parts.

Sand Preparation and Control

The quality and consistency of the sand used in the sand casting molding process play a crucial role in achieving tight dimensional tolerances. Proper sand preparation and control involve:

- Careful selection of sand grain size and distribution to optimize mold strength and surface finish

- Precise control of sand moisture content to ensure proper compaction and mold integrity

- Regular testing and monitoring of sand properties, including permeability, compactability, and green strength

- Implementation of automated sand mixing and reclamation systems to maintain consistent sand quality

By implementing rigorous sand control measures, foundries can minimize mold-related dimensional variations and improve overall casting accuracy.

Process Optimization and Monitoring

Continuous process optimization and monitoring are essential for maintaining tight dimensional tolerances in sand casting. This involves:

- Implementing statistical process control (SPC) techniques to identify and address sources of variation

- Utilizing advanced sensors and data acquisition systems to monitor critical process parameters in real-time

- Developing and maintaining detailed process documentation and standard operating procedures

- Conducting regular operator training and skill development programs to ensure consistent execution of best practices

By adopting a data-driven approach to process optimization, foundries can achieve more consistent and predictable dimensional outcomes in their sand casting operations.

Quality Control and Inspection Methods for Dimensional Tolerance

Advanced Measurement Technologies

Implementing advanced measurement technologies is crucial for ensuring dimensional accuracy in sand cast parts. Modern foundries utilize a range of sophisticated tools and techniques, including:

- Coordinate Measuring Machines (CMMs): These highly accurate machines use touch probes or laser scanners to measure complex geometries and generate detailed 3D models of cast parts.

- Optical Scanning Systems: Non-contact measurement devices that use structured light or laser technology to capture precise surface data and detect deviations from CAD models.

- CT Scanning: Computed tomography scanning allows for internal inspection of cast parts, revealing hidden defects and internal geometries without destructive testing.

By leveraging these advanced technologies, foundries can perform rapid and accurate dimensional inspections, enabling faster feedback loops and continuous improvement of their casting processes.

Statistical Process Control (SPC) Implementation

Statistical Process Control is a powerful tool for monitoring and improving dimensional tolerance in sand casting. Key aspects of SPC implementation include:

- Establishing control charts to track critical dimensions and identify trends or shifts in the process

- Calculating process capability indices (Cp and Cpk) to assess the ability of the process to meet specified tolerances

- Implementing root cause analysis techniques to address sources of variation and out-of-tolerance conditions

- Developing corrective action plans and preventive measures based on statistical data and trend analysis

By adopting a data-driven approach through SPC, foundries can proactively manage dimensional variations and continuously improve their casting processes.

Non-Destructive Testing (NDT) Methods

Non-destructive testing methods play a crucial role in ensuring the dimensional integrity and overall quality of sand cast parts. Common NDT techniques used in the foundry industry include:

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal defects and measure wall thickness in cast parts

- Radiographic Inspection: Employs X-rays or gamma rays to reveal internal discontinuities and verify dimensional accuracy of hidden features

- Magnetic Particle Inspection: Detects surface and near-surface defects in ferromagnetic materials, which can affect dimensional accuracy

By incorporating these NDT methods into their quality control processes, foundries can ensure that their sand cast parts meet both dimensional and structural integrity requirements.

Conclusion

Mastering dimensional tolerance control in sand casting is crucial for producing high-quality, precision components that meet the demanding requirements of modern industries. By implementing advanced pattern design techniques, optimizing sand preparation processes, and leveraging cutting-edge measurement and quality control methods, foundries can significantly enhance their dimensional accuracy capabilities. Continuous improvement through statistical process control and investment in advanced technologies will enable sand casting operations to maintain a competitive edge in the global manufacturing landscape.

FAQs

1. What is the typical dimensional tolerance range for sand casting?

Typical tolerances range from ±0.5mm to ±3mm, depending on the part size and complexity.

2. How does sand quality affect dimensional tolerance?

Sand quality, including grain size and moisture content, directly impacts mold stability and, consequently, dimensional accuracy.

3. Can 3D printing improve pattern accuracy in sand casting?

Yes, 3D printing enables the creation of highly precise patterns, contributing to improved dimensional accuracy in the final castings.

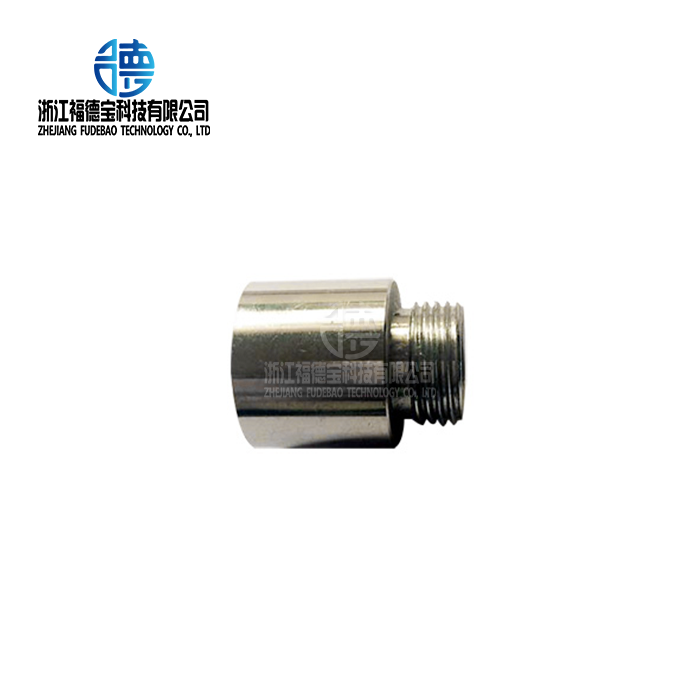

Expert Sand Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in precision sand casting and machining for various industries. Our state-of-the-art foundry utilizes advanced technologies to achieve tight dimensional tolerances, ensuring high-quality components for automotive, industrial, and aerospace applications. As a leading sand casting supplier and manufacturer, we offer comprehensive solutions from design to finished products. Contact us at hank.shen@fdbcasting.com to discuss your casting needs.

References

1. Smith, J. (2020). Advanced Techniques in Sand Casting Tolerance Control. Journal of Foundry Engineering, 45(2), 78-92.

2. Johnson, A., & Brown, R. (2019). Statistical Process Control in Modern Foundries. International Journal of Metalcasting, 13(4), 856-870.

3. Lee, K., et al. (2021). Dimensional Accuracy Improvement in Sand Casting Using 3D Printed Patterns. Additive Manufacturing, 38, 101807.

4. Zhang, Y., & Wang, L. (2018). Non-Destructive Testing Methods for Sand Cast Components: A Comprehensive Review. Materials Evaluation, 76(5), 650-668.

5. Miller, S. (2022). Sand Properties and Their Impact on Casting Dimensional Stability. Foundry Management & Technology, 150(3), 22-28.

6. Thompson, R. (2020). Quality Control Strategies for Precision Sand Casting. Advanced Materials & Processes, 178(6), 30-35.

YOU MAY LIKE

_1756352712247.webp)