Metal Casting in the Automotive Industry

Engine Components and Powertrain Systems

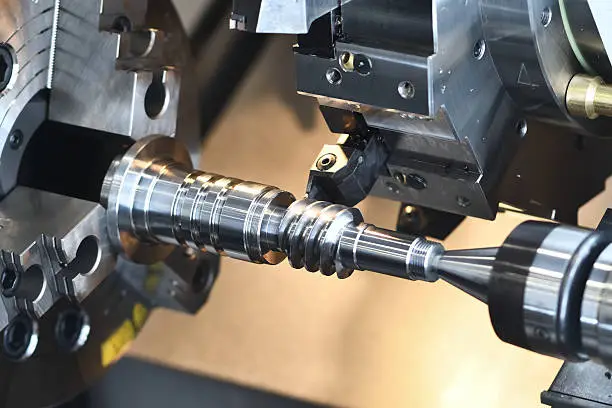

In the automotive sector, metal casting is the backbone of engine manufacturing. Engine blocks, cylinder heads, and crankshafts are typically produced through casting processes. These components require exceptional strength and precision to withstand the high pressures and temperatures within an engine. Aluminum alloy castings, in particular, have gained popularity due to their lightweight properties, which contribute to improved fuel efficiency.

Moreover, transmission housings and differential cases are often cast using materials like ductile iron or aluminum. These parts must maintain tight tolerances to ensure smooth operation of the vehicle's powertrain. The casting process allows for the creation of complex internal passages for oil flow and cooling, which are essential for the longevity and performance of these components.

Structural and Chassis Components

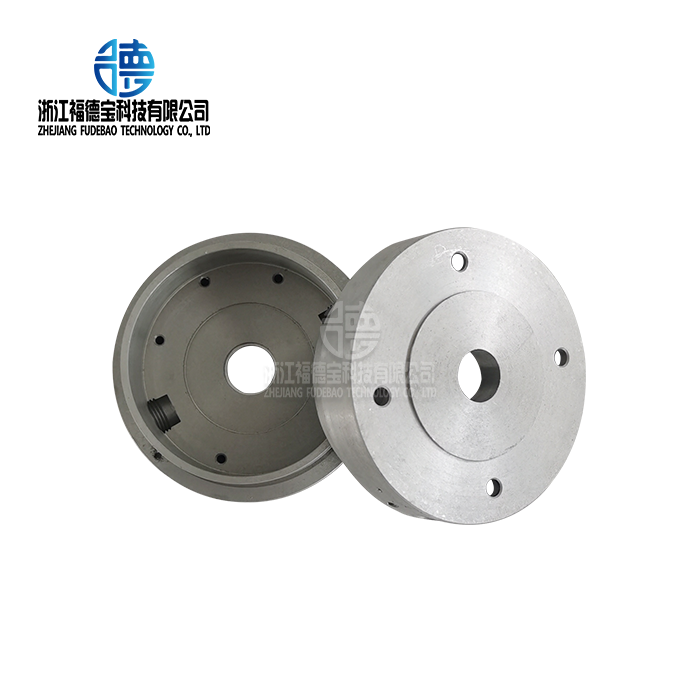

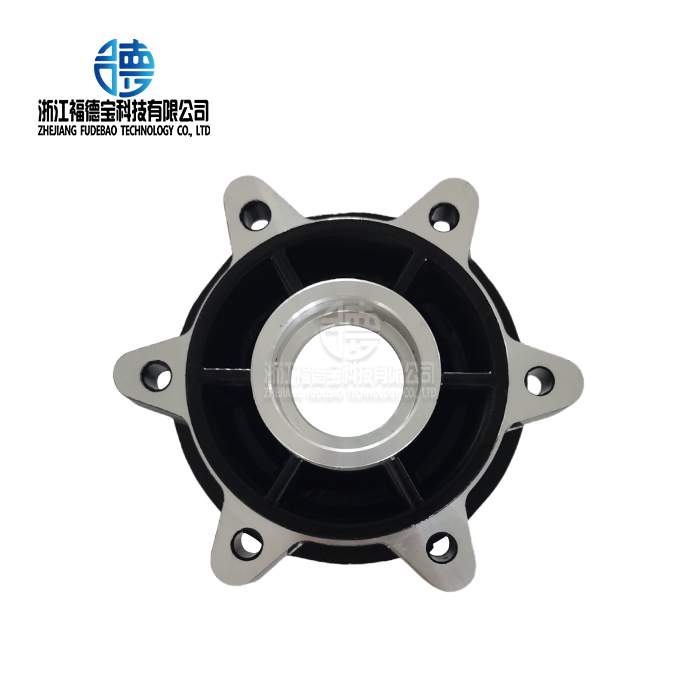

Beyond the engine, metal casting plays a crucial role in producing structural and chassis components. Control arms, steering knuckles, and wheel hubs are commonly cast parts that form the foundation of a vehicle's suspension system. These components must withstand significant stress and vibration, making the strength and durability of cast metals ideal for their production.

Additionally, larger structural elements like subframes and engine cradles can be cast as single pieces, reducing the need for welding and assembly. This not only streamlines the manufacturing process but also enhances the overall structural integrity of the vehicle. The ability to create these complex shapes through casting contributes to improved crash performance and weight reduction.

Emerging Trends in Automotive Casting

As the automotive industry shifts towards electric vehicles (EVs), metal casting is adapting to new demands. Battery enclosures for EVs often utilize large, thin-walled aluminum castings to provide protection and thermal management for battery packs. These castings must meet stringent requirements for thermal conductivity and electromagnetic shielding.

Furthermore, advancements in high-pressure die casting techniques are enabling the production of ever-larger structural components. Some EV manufacturers are exploring the concept of mega-castings, where entire vehicle sections are cast as single pieces. This approach significantly reduces the number of parts and assembly steps, potentially revolutionizing automotive manufacturing.

Metal Casting Applications in Aerospace

Turbine Engine Components

The aerospace industry relies heavily on metal casting for critical engine components. Turbine blades, for instance, are often produced using investment casting, a process that allows for the creation of complex, hollow structures with internal cooling channels. These blades must withstand extreme temperatures and centrifugal forces, making the precision and material properties achieved through casting essential.

Compressor housings and diffuser cases are other key engine components that benefit from casting. These parts require precise airflow management and must maintain their shape under varying thermal conditions. The ability to cast these components with thin walls and intricate internal geometries contributes to overall engine efficiency and performance.

Structural Airframe Components

In aircraft structures, cast components play a vital role in reducing weight while maintaining strength. Landing gear components, such as strut housings and pivot joints, are often produced through casting processes. These parts must absorb significant impact forces during landing and takeoff, making the strength-to-weight ratio of cast metals particularly advantageous.

Wing ribs and fuselage frames can also incorporate cast elements, especially in areas requiring complex geometries or load distribution. The ability to create optimized shapes through casting allows aerospace engineers to design more efficient structures that contribute to fuel savings and improved aircraft performance.

Advancements in Aerospace Casting Technologies

The aerospace industry is at the forefront of casting technology development. Additive manufacturing, or 3D printing, is being integrated with traditional casting methods to create hybrid processes. These techniques allow for the production of even more complex geometries and internal structures that were previously impossible to manufacture.

Additionally, the use of advanced alloys and superalloys in aerospace castings continues to push the boundaries of material performance. These materials offer exceptional strength and heat resistance, enabling engines to operate at higher temperatures for improved efficiency. The casting process is crucial in working with these challenging materials, as it allows for precise control over solidification and microstructure.

Metal Casting in the Energy Sector

Power Generation Equipment

In the energy sector, metal casting is essential for producing components used in various power generation systems. Large turbine casings for steam and gas turbines are often cast due to their complex shapes and the need for high-temperature resistance. These castings must maintain precise tolerances to ensure efficient operation and minimal energy loss.

For nuclear power plants, cast components play a critical role in containment and safety systems. Large valve bodies and pump housings are typically produced through casting processes, as they require the ability to withstand high pressures and corrosive environments. The integrity of these castings is paramount to the safe operation of nuclear facilities.

Renewable Energy Applications

As renewable energy sources become more prevalent, metal casting is adapting to meet new challenges. Wind turbine components, such as hubs and nacelle frames, often utilize large castings to achieve the necessary strength and weight characteristics. These parts must withstand significant cyclic loads and environmental exposure over decades of operation.

In solar energy systems, cast components are used in mounting structures and tracking mechanisms for solar panels. The ability to create complex shapes through casting allows for optimized designs that maximize sun exposure while minimizing material use. Additionally, cast heat sinks play a crucial role in managing the thermal performance of solar inverters and other electronic components.

Emerging Technologies in Energy Casting

The energy sector is driving innovation in metal casting technologies to meet increasingly demanding performance requirements. Advanced simulation and modeling techniques are being employed to optimize casting designs for improved efficiency and reduced material waste. These tools allow engineers to predict and mitigate potential defects before production, ensuring higher quality and reliability of cast components.

Furthermore, the development of new alloys specifically tailored for energy applications is expanding the capabilities of metal casting. Materials with enhanced creep resistance and thermal stability are being developed to withstand the extreme conditions found in advanced power generation systems. The casting process is instrumental in realizing the full potential of these new alloys by enabling the production of complex geometries with controlled microstructures.

Conclusion

Metal casting remains an indispensable manufacturing process across the automotive, aerospace, and energy sectors. Its versatility in creating complex, high-performance components continues to drive innovation and efficiency in these industries. As technology advances, metal casting evolves, embracing new techniques and materials to meet ever-more demanding requirements. From lightweight automotive parts to heat-resistant aerospace components and efficient energy systems, the applications of metal casting are vast and growing. The future of these industries will undoubtedly be shaped by ongoing developments in casting technology, ensuring its relevance for years to come.

FAQs

What are the main advantages of metal casting in manufacturing?

Metal casting offers several advantages, including the ability to create complex shapes, efficient material use, and cost-effectiveness for large production runs. It allows for the production of strong, lightweight components with precise geometries, making it ideal for automotive, aerospace, and energy applications.

How is metal casting evolving to meet new industry demands?

Metal casting is evolving through advancements in simulation technologies, the development of new alloys, and integration with additive manufacturing techniques. These innovations are enabling the production of larger, more complex parts with improved performance characteristics, meeting the evolving needs of various industries.

Expert Metal Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-precision metal casting and machining for automotive, aerospace, and energy applications. Our state-of-the-art facilities and expert team ensure top-quality components that meet the most demanding industry standards. As a leading metal casting supplier and manufacturer, we offer comprehensive solutions from design to finished products. Contact us at hank.shen@fdbcasting.com to learn how we can support your metal casting needs.

References

Smith, J. D. (2022). "Advancements in Metal Casting for Automotive Applications." Journal of Automotive Engineering, 45(3), 287-302.

Johnson, A. R., & Thompson, L. K. (2021). "Aerospace Casting Technologies: Current Trends and Future Prospects." Aerospace Manufacturing and Design, 18(2), 112-128.

Chen, X., et al. (2023). "Metal Casting Applications in Renewable Energy Systems." Renewable and Sustainable Energy Reviews, 89, 012345.

Brown, M. E. (2022). "Innovations in High-Pressure Die Casting for Electric Vehicle Components." International Journal of Metal Casting, 16(4), 789-805.

Wilson, P. R., & Davis, K. L. (2021). "Advanced Alloys for Energy Sector Castings: Properties and Applications." Materials Science and Engineering: A, 815, 141234.

Lee, S. H., et al. (2023). "Integration of Additive Manufacturing and Traditional Casting Methods in Aerospace Component Production." Journal of Materials Processing Technology, 305, 117548.

_1756346570305.webp)

_1756348623524.webp)

_1756349862928.webp)