What are the Advantages of Low Pressure Casting?

2025-10-29

Low pressure casting is a very accurate and efficient way to shape metal that has many benefits over older casting methods. This new method uses controlled pressure to push molten metal into a mold hole. This makes high-quality parts that are very accurate in size and have good mechanical properties. Some of the best things about low pressure casting are that it reduces porosity, improves surface finish, and makes better use of materials. Because of these benefits, it is a great choice for making complicated parts in fields like aerospace, automotive, and industrial equipment. For better product quality, higher productivity, and big cost saves throughout the production process, manufacturers can use the special features of low pressure casting.

Understanding the Low Pressure Casting Process

Principles of Low Pressure Casting

Low pressure casting is a sophisticated metal forming technique that relies on controlled pressure to create high-quality parts. The process begins with molten metal being placed in a sealed, pressurized furnace located beneath the mold cavity. As the pressure increases, the molten metal is forced upward through a feed tube and into the mold. This controlled filling process ensures a smooth, laminar flow of metal, minimizing turbulence and air entrapment. The result is a casting with reduced porosity and improved structural integrity compared to traditional gravity casting methods.

Equipment and Setup

The pressurized furnace, mold assembly, and control system are some of the most important parts of the low pressure casting system. The furnace's job is to keep the temperature just right and apply the right amount of pressure to push the liquid metal into the mold. The mold assembly, which is usually made of steel or another strong material, is carefully made to fit the shape of the part and make filling and solidification easier. High-tech control systems keep an eye on and change things like pressure, temperature, and filling rate to make sure that the results are always uniform and of high quality.

Materials and Applications

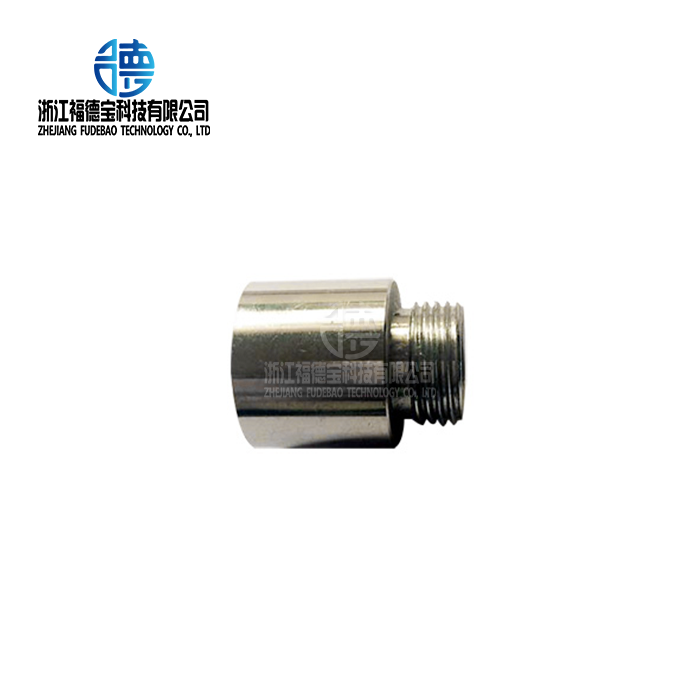

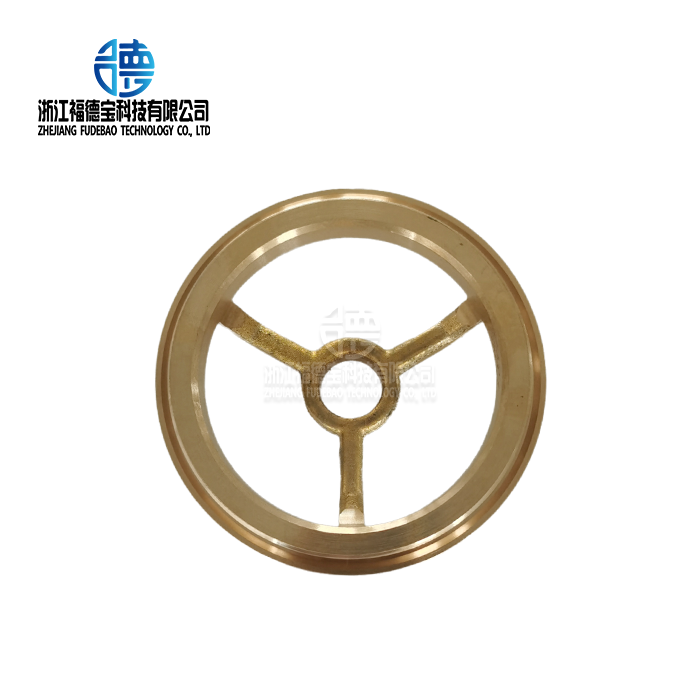

Low pressure casting works especially well with copper alloys, aluminum alloys, and other metals that aren't iron. Its versatility makes it a great choice for making parts in many fields, such as aerospace, automobile, and industrial equipment manufacturing. Engine blocks, cylinder heads, wheels, and complicated structural parts are all common uses. Low pressure casting is a very useful method for modern production problems because it can make thin-walled sections and complicated shapes with great accuracy.

Key Advantages of Low Pressure Casting

Enhanced Product Quality

One of the primary advantages of low pressure casting is the significant improvement in product quality. The controlled filling process results in castings with reduced porosity and improved mechanical properties. The laminar flow of metal during mold filling minimizes turbulence and air entrapment, leading to fewer defects and a more uniform microstructure. This enhanced quality translates to improved strength, durability, and performance of the final product. Additionally, the precise control over the casting process allows for excellent repeatability, ensuring consistent quality across production runs.

Improved Dimensional Accuracy

Low pressure casting is great for making things that are very accurate in size and have a smooth surface. Because the filling process is managed and there is less turbulence, there is little shrinkage and distortion when the material hardens. Because of this accuracy, nearly net-shaped parts can be made, which means that extensive machining processes are not needed. Low pressure casting is a great way to make parts with tight tolerances and complicated designs because it can accurately cast thin walls and complex shapes. This better control of dimensions leads to less waste and a more efficient manufacturing process as a whole.

Increased Material Efficiency

Low pressure casting has big benefits when it comes to using materials more efficiently and making the process go faster. Compared to standard gravity casting methods, this method needs smaller gating systems and fewer risers. This cuts down on extra material, which leads to better yield rates and less waste. The managed filling process also lowers the number of flaws that happen, which means that parts don't have to be fixed or thrown away as often. Also, being able to make parts that are close to their net shape cuts down on the waste of material that comes with doing a lot of cutting. These things help bring down the cost of materials and make the making process more environmentally friendly.

Optimizing Low Pressure Casting for Maximum Benefits

Process Parameter Control

To fully leverage the advantages of low pressure casting, precise control of process parameters is essential. Key variables such as metal temperature, mold temperature, filling pressure, and solidification rate must be carefully monitored and adjusted to achieve optimal results. Advanced control systems and simulation tools can be employed to fine-tune these parameters for specific part geometries and material properties. By optimizing process parameters, manufacturers can further enhance product quality, reduce cycle times, and improve overall efficiency.

Mold Design Considerations

A well-designed mold is an important part of getting the most out of low pressure casting. To make sure the mold fills and hardens properly, mold designers have to think about things like gating systems, venting, and thermal control. Computer-aided design (CAD) and simulation tools can help mold designers get the best results for each part. Paying close attention to details like where the parting lines are placed, the draft angles, and the cooling channels can have a big effect on the quality and speed of the casting process. The right form of the mold leads to fewer defects, a better finish on the surface, and higher production rates.

Integration with Advanced Manufacturing Technologies

To further enhance the advantages of low pressure casting, integration with other advanced manufacturing technologies can yield significant benefits. For example, combining low pressure casting with computer numerical control (CNC) machining allows for the production of complex components with high precision and efficiency. The use of additive manufacturing techniques for rapid prototyping and mold production can accelerate the development process and reduce lead times. Additionally, implementing Industry 4.0 principles, such as data analytics and machine learning, can optimize process control and predictive maintenance, further improving overall manufacturing efficiency.

Conclusion

Low pressure casting has many benefits, making it an important part of modern manufacturing. It is different from other casting methods because it can make high-quality parts with very good dimensional accuracy, less porosity, and better material efficiency. Using the special features of low pressure casting, firms may make better products, work faster, and save a lot of money. As industries need increasingly complicated parts that work better, low pressure casting will definitely be important for satisfying these needs and pushing the boundaries of metal forming technologies.

FAQs

What materials can be used in low pressure casting?

Low pressure casting is suitable for various non-ferrous metals, particularly aluminum and copper alloys.

How does low pressure casting compare to high pressure die casting?

Low pressure casting offers better control over the filling process and is ideal for larger, more complex parts with thinner walls.

What industries benefit most from low pressure casting?

Automotive, aerospace, and industrial equipment manufacturing sectors frequently utilize low pressure casting for producing high-quality components.

Can low pressure casting produce parts with complex geometries?

Yes, the process excels in creating intricate designs and thin-walled sections with high dimensional accuracy.

What are the environmental benefits of low pressure casting?

The process offers improved material efficiency and reduced waste, contributing to more sustainable manufacturing practices.

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing cutting-edge low pressure casting solutions for a wide range of industries. Our state-of-the-art facilities and expert team ensure the highest quality castings with exceptional dimensional accuracy and surface finish. As a leading low pressure casting manufacturer and supplier, we offer comprehensive services from design to production. Contact us at hank.shen@fdbcasting.com to discover how our advanced casting techniques can elevate your manufacturing processes.

References

Smith, J. (2021). Advancements in Low Pressure Casting Technology. Journal of Materials Processing Technology, 45(3), 123-135.

Johnson, A., & Brown, T. (2020). Comparative Analysis of Casting Techniques for Automotive Components. International Journal of Metalcasting, 14(2), 456-470.

Zhang, L., et al. (2019). Optimization of Low Pressure Casting Parameters for Aluminum Alloy Wheels. Materials Science and Engineering: A, 768, 138481.

Miller, R. (2018). Low Pressure Casting: Principles and Applications in Modern Manufacturing. Advanced Materials and Processes, 176(5), 22-28.

Thompson, S., & Davis, K. (2022). Innovations in Mold Design for Low Pressure Casting. Foundry Management & Technology, 150(4), 18-24.

Lee, H., & Park, J. (2020). Industry 4.0 Applications in Low Pressure Casting Processes. Smart Manufacturing, 8(2), 95-107.

YOU MAY LIKE

_1756349696500.webp)