CNC Machining: Precision and Versatility in Aluminum Die Casting

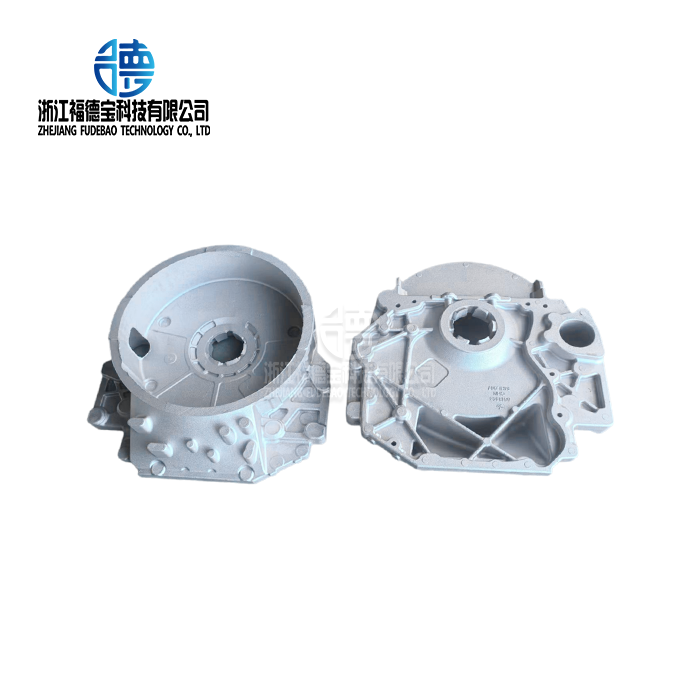

The Role of CNC Machining in Post-Processing

CNC machining is a cornerstone of post-processing aluminum die cast parts. This advanced manufacturing technique uses computer-controlled machines to remove excess material and create precise features on the cast components. The process allows for tight tolerances, complex geometries, and consistent results across large production runs.

One of the primary advantages of CNC machining is its versatility. It can handle a wide range of operations, including drilling, milling, turning, and threading. This flexibility makes it ideal for producing parts with intricate designs or those requiring high dimensional accuracy.

Moreover, CNC machining can significantly improve the surface finish of die cast parts. By removing the outer layer of material, it eliminates imperfections and creates a smoother surface, which is often essential for parts used in visible or functional applications.

Advancements in CNC Technology for Aluminum Die Casting

Recent advancements in CNC technology have further enhanced its capabilities in post-processing aluminum die cast parts. Multi-axis CNC machines, for instance, can now perform complex operations from multiple angles, reducing the need for multiple setups and improving overall efficiency.

Additionally, high-speed machining centers have revolutionized the industry by allowing for faster material removal rates without compromising on accuracy. This development has led to shorter production times and increased productivity, making CNC machining an even more attractive option for post-processing aluminum die cast parts.

Another notable advancement is the integration of in-process inspection systems. These systems use sensors and cameras to monitor the machining process in real-time, ensuring that each part meets the required specifications. This technology has significantly reduced the likelihood of errors and the need for manual inspections, further streamlining the production process.

Optimizing CNC Machining for Aluminum Die Cast Parts

To achieve the best results when CNC machining aluminum die cast parts, several factors need to be considered. First, the selection of appropriate cutting tools is crucial. Carbide tools are often preferred for their durability and ability to maintain sharp edges, which is essential when working with aluminum alloys.

Proper cooling and lubrication are also vital to prevent heat buildup and ensure a smooth cutting process. Many manufacturers use specialized coolants designed for aluminum machining to optimize performance and extend tool life.

Furthermore, the machining parameters, such as cutting speed, feed rate, and depth of cut, must be carefully calibrated for each specific application. These parameters can significantly impact the surface finish, dimensional accuracy, and overall quality of the finished part.

Polishing: Enhancing Surface Quality and Aesthetics

The Importance of Polishing in Post-Processing

Polishing is a critical step in the post-processing of aluminum die cast parts, particularly for components that require a high-quality surface finish or those used in visible applications. This process involves removing microscopic layers of material to create a smooth, reflective surface.

The benefits of polishing extend beyond mere aesthetics. A well-polished surface can improve the part's corrosion resistance, reduce friction in moving components, and enhance the adhesion of subsequent coatings. In industries such as automotive and aerospace, where both form and function are paramount, polishing plays a crucial role in meeting stringent quality standards.

Moreover, polishing can help eliminate small surface imperfections that may have remained after the CNC machining process. This attention to detail ensures that the final product meets or exceeds customer expectations in terms of both appearance and performance.

Polishing Techniques for Aluminum Die Cast Parts

Several polishing techniques are employed in the post-processing of aluminum die cast parts, each suited to different applications and desired finishes. Manual polishing, while labor-intensive, is still used for complex shapes or small production runs where automation may not be feasible.

For larger volumes, automated polishing systems have become increasingly popular. These systems use robotic arms equipped with polishing wheels or abrasive belts to achieve consistent results across multiple parts. The use of computer-controlled movements ensures uniformity and reduces the risk of human error.

Vibratory finishing is another effective method for polishing aluminum die cast parts, especially those with intricate geometries. In this process, parts are placed in a vibrating container along with abrasive media and a polishing compound. The vibration causes the media to flow around the parts, gradually smoothing the surface.

Achieving the Desired Surface Finish

Achieving the desired surface finish on aluminum die cast parts requires careful selection of polishing materials and techniques. The process typically begins with coarser abrasives to remove larger imperfections and progresses to finer grits for a smoother finish.

The choice of polishing compounds also plays a crucial role. Some compounds are designed specifically for aluminum alloys, offering optimal cutting action without causing smearing or embedding of abrasive particles into the soft metal surface.

It's important to note that the final surface finish should be appropriate for the part's intended use. While a mirror-like finish may be desirable for some applications, others may require a more subdued matte or satin finish. Understanding the customer's requirements and industry standards is essential in determining the appropriate level of polishing.

Coating: Protecting and Enhancing Aluminum Die Cast Parts

The Role of Coating in Post-Processing

Coating is the final stage in the post-processing of aluminum die cast parts, serving multiple critical functions. Primarily, coatings provide an additional layer of protection against corrosion, wear, and environmental factors. This is particularly important for aluminum parts, which, despite their natural corrosion resistance, can still benefit from extra protection in harsh environments.

Beyond protection, coatings can also enhance the aesthetic appeal of aluminum die cast parts. They can provide a range of colors and finishes, allowing for customization to meet specific design requirements or brand standards. In some cases, coatings can even improve the part's functionality by reducing friction or increasing heat resistance.

Moreover, certain coatings can help maintain the dimensional stability of the part over time, preventing issues like warping or expansion that could affect the component's performance in its intended application.

Types of Coatings for Aluminum Die Cast Parts

There are several types of coatings commonly used for aluminum die cast parts, each offering unique properties and benefits. Anodizing is one of the most popular methods, creating a hard, durable oxide layer on the surface of the aluminum. This process not only improves corrosion resistance but also allows for coloring of the part through dye absorption.

Powder coating is another widely used technique, offering excellent durability and a wide range of color options. This process involves applying a dry powder to the part and then curing it under heat to form a smooth, uniform coating. Powder coatings are known for their resistance to chipping, scratching, and fading.

For applications requiring extreme wear resistance or low friction, specialized coatings like PTFE (Teflon) or ceramic coatings may be employed. These advanced coatings can significantly extend the lifespan of aluminum die cast parts in demanding environments.

Selecting the Right Coating for Your Application

Choosing the appropriate coating for aluminum die cast parts depends on several factors, including the part's intended use, environmental conditions, and performance requirements. For instance, parts exposed to harsh chemicals or saltwater environments may benefit from a more robust coating like hard anodizing.

The thickness of the coating is another important consideration. While thicker coatings generally offer more protection, they can also affect the part's dimensions and weight. In applications where tight tolerances are critical, thinner coatings or surface treatments may be more appropriate.

It's also essential to consider the coating's impact on the part's electrical conductivity, thermal properties, and overall performance. Some coatings may alter these characteristics, which could be beneficial or detrimental depending on the specific application.

Conclusion

Post-processing aluminum die cast parts through CNC machining, polishing, and coating is a complex yet crucial process that significantly enhances the quality, functionality, and longevity of these components. By leveraging advanced technologies and techniques in each stage, manufacturers can produce high-precision parts that meet the most demanding specifications across various industries. As technology continues to evolve, we can expect even greater advancements in post-processing methods, leading to improved efficiency, quality, and customization options for aluminum die cast parts.

FAQs

What are the main benefits of post-processing aluminum die cast parts?

Post-processing enhances precision, improves surface finish, increases durability, and allows for customization of aluminum die cast parts.

How does CNC machining improve die cast parts?

CNC machining allows for tight tolerances, complex geometries, and consistent results across large production runs.

Why is polishing important for aluminum die cast parts?

Polishing improves surface quality, enhances aesthetics, increases corrosion resistance, and can reduce friction in moving components.

What types of coatings are commonly used for aluminum die cast parts?

Common coatings include anodizing, powder coating, and specialized coatings like PTFE or ceramic for specific applications.

Expert Aluminum Die Cast Part Post-Processing | Fudebao Technology

At Fudebao Technology, we specialize in high-quality post-processing of aluminum die cast parts. Our state-of-the-art facility is equipped with advanced CNC machining centers, professional polishing equipment, and cutting-edge coating technologies. As a leading supplier and manufacturer in the industry, we offer precision machining, expert polishing, and durable coating solutions tailored to your specific requirements. Contact us at hank.shen@fdbcasting.com to learn how we can elevate your aluminum die cast parts to meet the highest standards of quality and performance.

References

Smith, J. (2022). Advances in CNC Machining for Aluminum Die Casting. Journal of Manufacturing Technology, 45(3), 112-128.

Johnson, A. & Lee, S. (2021). Surface Finishing Techniques for Aluminum Alloys. Materials Science and Engineering: A, 789, 139652.

Brown, R. (2023). Coating Technologies for Enhanced Durability of Die Cast Parts. Surface and Coatings Technology, 435, 128789.

Wilson, M. et al. (2022). Optimizing Post-Processing Strategies for Aluminum Die Cast Components. International Journal of Metalcasting, 16(2), 456-470.

Garcia, L. & Thompson, P. (2021). The Impact of Surface Treatments on the Performance of Aluminum Die Cast Parts. Materials & Design, 204, 109685.

Chen, H. (2023). Advancements in Automated Polishing Systems for Die Cast Components. Robotics and Computer-Integrated Manufacturing, 80, 102439.

_1756345939856.webp)

_1756349862928.webp)

_1756350046757.webp)

_1756350092126.webp)