Evaluating Technical Capabilities and Expertise

Assessing Machine Capabilities and Technology

When choosing a CNC machining supplier, it's essential to evaluate their technical capabilities and expertise. Start by assessing the types of CNC machines they operate. Look for suppliers with a diverse range of advanced equipment, including high-speed machining centers, multi-axis CNC lathes, and precision grinding machines. These capabilities ensure that the supplier can handle a variety of complex parts and materials.

Additionally, inquire about the supplier's software and CAD/CAM systems. Modern CNC programming software enables efficient production and can significantly impact the quality and consistency of machined parts. A supplier using up-to-date technology is more likely to deliver precise and reliable results.

Examining Material Expertise

The right CNC machining supplier should have extensive experience working with a wide range of materials. This expertise is crucial for ensuring optimal machining parameters and surface finishes. Ask about their familiarity with materials relevant to your industry, such as aluminum alloys, stainless steel, or specialized plastics.

Moreover, consider suppliers who offer material recommendations based on your project requirements. Their knowledge can help you select the most suitable materials for your application, potentially improving performance and reducing costs.

Verifying Industry Experience

Industry-specific experience is a valuable asset when selecting a CNC machining supplier. Look for providers with a proven track record in your particular sector, whether it's automotive, aerospace, medical devices, or industrial equipment. This experience often translates to a deeper understanding of industry standards, regulatory requirements, and specific challenges associated with your type of parts.

Request case studies or examples of similar projects they've completed in your industry. This information can give you insights into their problem-solving abilities and how they've tackled challenges similar to yours.

Quality Assurance and Certification

Understanding Quality Control Processes

Quality assurance is paramount in CNC machining. A reputable supplier should have robust quality control processes in place. Inquire about their inspection methods, including the use of coordinate measuring machines (CMMs), optical comparators, and other precision measurement tools. These technologies ensure that machined parts meet your exact specifications.

Ask about their quality management system and how they handle non-conforming parts. A supplier with a well-documented quality control process can provide consistent results and quickly address any issues that may arise during production.

Verifying Industry Certifications

Certifications are a strong indicator of a supplier's commitment to quality and industry standards. Look for suppliers with relevant certifications such as ISO 9001 for quality management systems, AS9100 for aerospace industry standards, or ISO 13485 for medical device manufacturing.

These certifications demonstrate that the supplier adheres to internationally recognized quality standards and undergoes regular audits to maintain their certification status. This commitment to quality can give you confidence in their ability to meet your specifications consistently.

Assessing Continuous Improvement Initiatives

A forward-thinking CNC machining supplier should have ongoing initiatives for continuous improvement. Ask about their approach to lean manufacturing, Six Sigma methodologies, or other process improvement techniques. Suppliers who invest in these practices often deliver better quality, faster turnaround times, and more competitive pricing.

Additionally, inquire about their training programs for machine operators and quality control personnel. Regular training ensures that the supplier's team stays up-to-date with the latest machining techniques and quality assurance practices.

Customer Service and Project Management

Evaluating Communication and Responsiveness

Effective communication is crucial for successful CNC machining projects. Assess the supplier's responsiveness during your initial inquiries. A reliable partner should be prompt in addressing your questions and providing detailed information about their services.

Look for suppliers who offer clear channels of communication, such as dedicated project managers or online portals for tracking orders and accessing documentation. These tools can streamline your interactions and keep you informed throughout the production process.

Analyzing Project Management Capabilities

Efficient project management is essential for meeting deadlines and managing complex manufacturing projects. Inquire about the supplier's approach to project planning and execution. Do they use project management software? How do they handle change orders or design modifications?

A supplier with strong project management skills can help you navigate challenges, optimize production schedules, and ensure that your parts are delivered on time and within budget. This capability is particularly important for large-scale or ongoing manufacturing projects.

Considering Flexibility and Scalability

Your CNC machining needs may change over time, so it's important to choose a supplier that can adapt to your evolving requirements. Assess their ability to handle both small prototype runs and large-scale production orders. Can they quickly adjust to changes in volume or design specifications?

Additionally, consider their capacity for future growth. A supplier that continues to invest in new technologies and expand their capabilities can support your business as it grows, potentially becoming a long-term manufacturing partner.

Conclusion

Selecting the right CNC machining supplier is a critical decision that can significantly impact your product quality, production efficiency, and overall business success. By thoroughly evaluating technical capabilities, quality assurance measures, and customer service practices, you can identify a supplier that aligns with your specific needs. Remember to consider factors such as industry experience, certifications, and the ability to scale with your business. Taking the time to carefully assess potential suppliers will help you forge a successful partnership that supports your manufacturing goals and drives innovation in your industry.

FAQs

What are the key factors to consider when choosing a CNC machining supplier?

Key factors include technical capabilities, quality assurance processes, industry experience, certifications, communication skills, and project management abilities.

How important are industry certifications for a CNC machining supplier?

Certifications like ISO 9001 and AS9100 are crucial as they demonstrate adherence to quality standards and industry-specific requirements.

What should I look for in terms of a supplier's technology and equipment?

Look for suppliers with advanced CNC machinery, up-to-date CAD/CAM software, and a range of capabilities to handle various materials and complex parts.

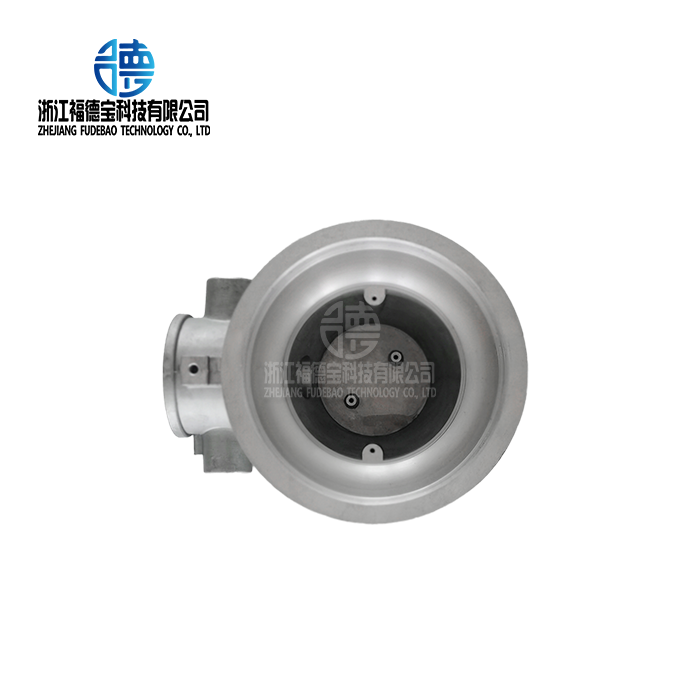

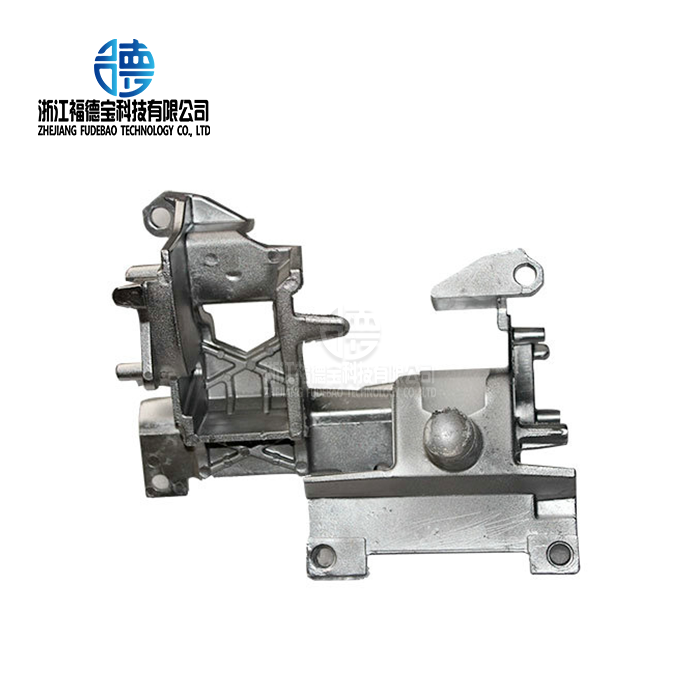

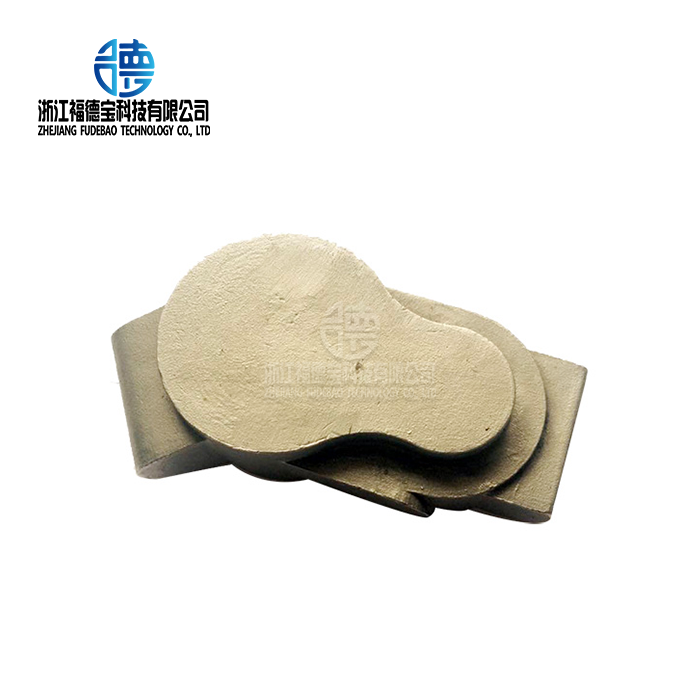

Expert CNC Machining Services | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for a wide range of industries. Our state-of-the-art facility is equipped with advanced CNC machines and staffed by skilled technicians, ensuring top-quality results for every project. We offer comprehensive services from prototyping to large-scale production, with a focus on aluminum alloy, copper alloy, and stainless steel components. Contact us at hank.shen@fdbcasting.com to discuss your CNC machining needs and experience our commitment to excellence.

References

Smith, J. (2022). "The Complete Guide to CNC Machining Supplier Selection." Manufacturing Today, 15(3), 45-52.

Johnson, R. & Brown, L. (2021). "Quality Assurance in CNC Machining: Best Practices and Standards." Journal of Precision Engineering, 28(2), 112-128.

Thompson, E. (2023). "Evaluating Technical Capabilities in CNC Machining Suppliers." Industrial Manufacturing Quarterly, 42(1), 78-85.

Lee, S. et al. (2022). "The Impact of Industry 4.0 on CNC Machining Processes and Supplier Selection." International Journal of Advanced Manufacturing Technology, 95(4), 1567-1582.

Wilson, M. (2021). "Customer Service Excellence in the CNC Machining Industry." Service Management Review, 33(2), 201-215.

Garcia, A. & Martinez, C. (2023). "Sustainability and Innovation in CNC Machining: A Supplier Perspective." Journal of Sustainable Manufacturing, 18(3), 302-318.

_1756352340434.webp)