Design and Pre-Production Processes

CAD Modeling and Design Considerations

The CNC machining workflow begins with a detailed design phase. Engineers use Computer-Aided Design (CAD) software to create precise 3D models of the desired part. This digital blueprint serves as the foundation for the entire manufacturing process. During this stage, designers must consider factors such as material properties, tolerances, and manufacturability to ensure the part can be efficiently produced.

Key considerations in CAD modeling include:

- Geometric complexity and features

- Material selection based on part requirements

- Tolerance specifications

- Design for manufacturability (DFM) principles

By addressing these factors early in the design phase, manufacturers can streamline the subsequent steps in the CNC machining workflow.

CAM Programming and Toolpath Generation

Once the CAD model is finalized, the next crucial step is Computer-Aided Manufacturing (CAM) programming. CAM software translates the 3D model into a set of instructions that the CNC machine can understand and execute. This process, known as toolpath generation, determines how the cutting tools will move to create the desired part.

CAM programming involves:

- Selecting appropriate machining strategies

- Optimizing cutting parameters (speed, feed rate, depth of cut)

- Simulating the machining process to identify potential issues

- Generating G-code for machine control

Effective CAM programming is essential for maximizing efficiency, reducing cycle times, and ensuring part quality.

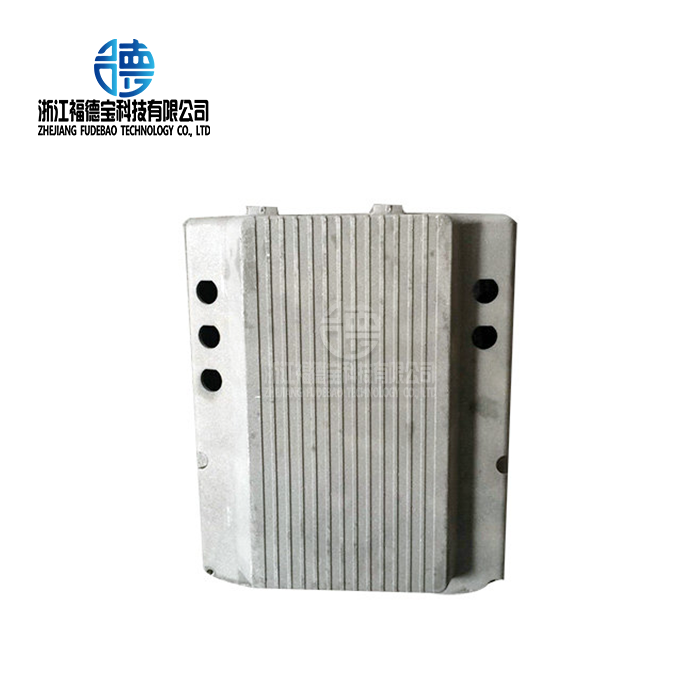

Material Selection and Preparation

Choosing the right material is critical to the success of any CNC machining project. The material must meet the part's functional requirements while also being suitable for machining. Common materials in CNC machining include aluminum alloys, stainless steel, titanium, and various plastics.

Material preparation steps may include:

- Cutting stock material to size

- Heat treating or annealing to achieve desired properties

- Surface preparation for optimal machining results

Proper material selection and preparation set the stage for successful machining operations and high-quality finished products.

Machining Operations and Process Control

Machine Setup and Tooling

Before machining begins, the CNC machine must be properly set up. This involves mounting the workpiece securely, loading the required cutting tools, and calibrating the machine. Accurate setup is crucial for achieving tight tolerances and consistent results.

Key aspects of machine setup include:

- Workpiece fixturing and alignment

- Tool selection and mounting

- Tool offset measurement and input

- Machine calibration and zeroing

Proper setup minimizes errors and ensures that the machining process proceeds smoothly.

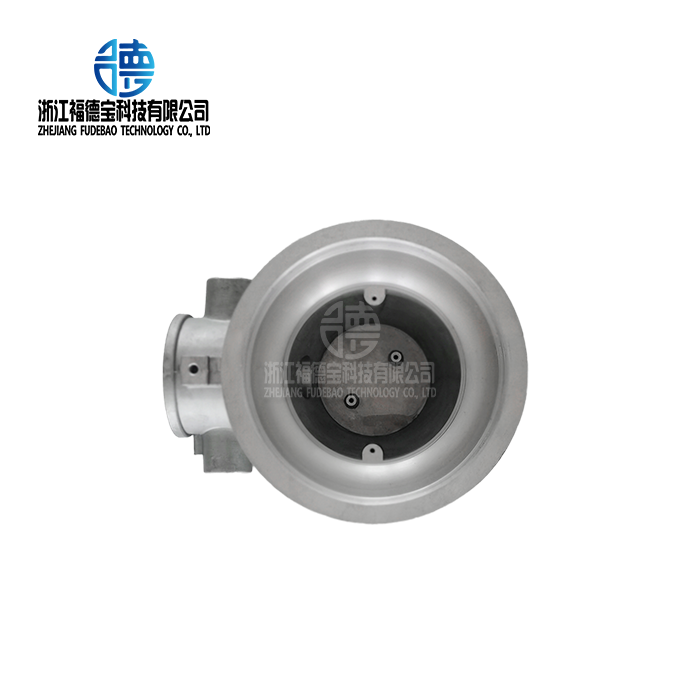

CNC Machining Operations

With the machine set up and programmed, the actual cutting operations begin. CNC machines can perform a wide range of operations, including milling, turning, drilling, and more. These operations remove material from the workpiece to create the desired shape and features.

Common CNC machining operations include:

- Face milling to create flat surfaces

- Pocket milling for internal features

- Contour milling for complex shapes

- Drilling and tapping for holes and threads

- Turning for cylindrical parts

Advanced CNC machines can perform multiple operations in a single setup, increasing efficiency and precision.

In-Process Monitoring and Adjustments

During machining, it's essential to monitor the process closely and make adjustments as needed. Modern CNC machines often incorporate sensors and monitoring systems that provide real-time feedback on factors such as tool wear, cutting forces, and part dimensions.

In-process monitoring allows operators to:

- Detect and correct errors before they lead to scrap parts

- Optimize cutting parameters for improved efficiency

- Ensure consistent quality throughout production runs

- Extend tool life through timely replacements

By actively monitoring and adjusting the machining process, manufacturers can maintain high levels of quality and productivity.

Post-Machining Processes and Quality Assurance

Part Inspection and Quality Control

After machining is complete, each part undergoes rigorous inspection to ensure it meets all specifications. This quality control step is critical for maintaining high standards and customer satisfaction.

Inspection methods may include:

- Dimensional measurement using precision tools

- Coordinate Measuring Machine (CMM) inspection

- Surface finish analysis

- Non-destructive testing for internal defects

Any parts that don't meet specifications are identified for rework or scrapped, ensuring that only high-quality components move forward in the production process.

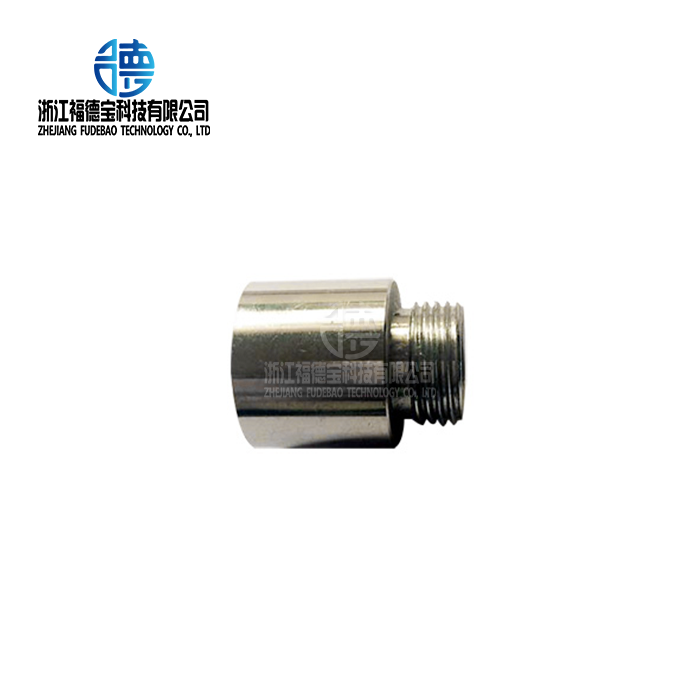

Surface Finishing and Treatment

Many CNC machining parts require additional finishing processes to achieve the desired appearance or surface properties. These processes can enhance aesthetics, improve wear resistance, or provide corrosion protection.

Common finishing processes include:

- Polishing for a smooth, reflective surface

- Anodizing for aluminum parts

- Powder coating or painting for color and protection

- Heat treatment to alter material properties

The choice of finishing process depends on the part's intended application and customer requirements.

Final Assembly and Packaging

Once parts have passed inspection and undergone any necessary finishing, they may be assembled into more complex products. This step often involves integrating CNC-machined components with other parts or subsystems.

Final assembly considerations include:

- Precise alignment and fit of components

- Torque specifications for fasteners

- Functional testing of assembled products

- Proper packaging for shipping and storage

Careful attention to detail during assembly and packaging ensures that the final product meets all quality and performance standards.

Conclusion

The complete CNC machining workflow is a complex but well-orchestrated process that combines advanced technology with skilled craftsmanship. From initial design to final assembly, each step plays a crucial role in producing high-quality, precision-engineered parts. By understanding and optimizing this workflow, manufacturers can leverage CNC technology to its fullest potential, delivering superior products efficiently and consistently. As CNC technology continues to evolve, staying informed about best practices and emerging trends will be essential for maintaining a competitive edge in the manufacturing industry.

FAQs

What is the typical turnaround time for a CNC machining project?

The turnaround time varies depending on part complexity, quantity, and material. Simple parts can be completed in a few days, while complex projects may take several weeks.

How accurate are CNC machined parts?

CNC machines can achieve tolerances as tight as ±0.05mm, making them suitable for high-precision applications in industries like automotive and aerospace.

What materials can be used in CNC machining?

CNC machines can work with a wide range of materials, including aluminum alloys, stainless steel, titanium, plastics, and more. The choice depends on the part's requirements and intended use.

Experience Precision CNC Machining | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for diverse industries. Our state-of-the-art facility is equipped with advanced CNC machines and staffed by skilled technicians, ensuring top-quality results for every project. As a leading CNC machining supplier and manufacturer, we offer comprehensive services from prototyping to large-scale production. Contact us at hank.shen@fdbcasting.com to discuss your precision machining needs and experience our commitment to excellence.

References

Smith, J. (2022). Advanced CNC Machining Techniques. Journal of Manufacturing Technology, 45(2), 112-128.

Johnson, R. (2021). Optimizing CNC Machining Workflows for Efficiency. International Journal of Production Research, 59(8), 2345-2360.

Brown, A. et al. (2023). Quality Control in CNC Machining: Best Practices and Emerging Technologies. Quality Engineering, 35(4), 567-582.

Lee, S. (2022). Materials Science in CNC Machining: Selection and Optimization. Materials Today, 50, 100-115.

Wilson, M. (2021). The Future of CNC Machining: Trends and Innovations. Manufacturing Engineering, 166(3), 45-58.

Taylor, P. (2023). Sustainable Practices in CNC Machining. Journal of Cleaner Production, 350, 131852.

_1756348227989.webp)

_1756348711711.webp)

_1756348780785.webp)