The Mechanics of Low Pressure Casting

Process Overview

Low pressure casting is an innovative metal forming technique that has gained popularity in recent years. The process begins with molten metal being placed in a pressurized furnace located beneath the mold cavity. As the pressure increases, the molten metal is forced upward through a feed tube and into the mold. This controlled filling ensures a smooth, turbulence-free flow of metal, resulting in high-quality castings with minimal defects.

Equipment and Setup

The low pressure casting system consists of several key components. The pressurized furnace, also known as the holding furnace, maintains the metal in its molten state. Above this sits the mold, typically made of steel or a similar durable material. The feed tube connects these two elements, allowing for the smooth transfer of molten metal. Additional equipment may include cooling systems, pressure regulators, and control units to manage the entire process with precision.

Material Considerations

While low pressure casting can be used with various metals, it's particularly well-suited for aluminum alloys. The process's controlled nature allows for excellent grain structure and reduced porosity in aluminum castings. Other materials that can be used include magnesium alloys, copper alloys, and even some grades of iron. The choice of material depends on the specific requirements of the final product, including strength, weight, and thermal properties.

Advantages of Low Pressure Casting

Enhanced Product Quality

One of the primary advantages of low pressure casting is the superior quality of the final product. The controlled filling of the mold cavity results in castings with minimal porosity and excellent surface finish. This process allows for the production of complex geometries with thin walls and intricate details that might be challenging to achieve with other casting methods. The slow, steady fill also reduces turbulence, leading to fewer defects and improved mechanical properties in the finished parts.

Material Efficiency

Low pressure casting boasts impressive material efficiency. The process minimizes waste by using only the amount of metal necessary to fill the mold cavity. Unlike some other casting methods, there's no need for large risers or extensive gating systems, which can consume significant amounts of material. This efficiency not only reduces raw material costs but also contributes to a more sustainable manufacturing process, aligning with modern environmental concerns.

Versatility in Design

The versatility of low pressure casting opens up a world of design possibilities. This method excels in producing parts with varying wall thicknesses, undercuts, and complex internal cavities. It's particularly adept at creating hollow castings, making it ideal for components like engine blocks, cylinder heads, and intricate automotive parts. The ability to produce near-net-shape castings also reduces the need for extensive post-casting machining, saving time and resources in the overall manufacturing process.

Limitations of Low Pressure Casting

Production Speed Constraints

While low pressure casting offers numerous advantages, it does have limitations in terms of production speed. The process is generally slower compared to high-pressure die casting or sand casting methods. Each cycle requires time for the mold to be filled slowly and for the casting to solidify under controlled conditions. This can result in lower production rates, which may be a significant consideration for high-volume manufacturing scenarios. Manufacturers must weigh the quality benefits against the potential impact on production capacity.

Initial Investment and Operating Costs

The initial investment for low pressure casting equipment can be substantial. The specialized furnaces, molds, and control systems required for this process often come with a higher price tag compared to simpler casting methods. Additionally, the ongoing operating costs, including energy consumption and maintenance of the pressurized systems, can be higher than traditional gravity casting techniques. These financial considerations may pose challenges for smaller manufacturers or those with limited capital resources.

Size and Weight Limitations

Low pressure casting has inherent limitations when it comes to the size and weight of castings that can be produced. The process is most effective for small to medium-sized parts, typically weighing up to about 100 kg. Larger castings become increasingly challenging due to the limitations of the pressure system and the difficulties in maintaining uniform solidification across a large mold. This size constraint may restrict the applicability of low pressure casting in certain industries or for specific large-scale components.

Conclusion

Low pressure casting stands out as a valuable technique in the metal forming industry, offering a balanced mix of advantages and limitations. Its ability to produce high-quality, complex parts with minimal waste makes it an attractive option for many manufacturers, particularly in industries demanding precision and performance. However, the slower production rates, higher initial costs, and size limitations must be carefully considered. As technology advances, we may see improvements that address some of these limitations, potentially expanding the applications of low pressure casting across various sectors.

FAQs

What types of metals are suitable for low pressure casting?

Low pressure casting is primarily used for aluminum alloys, but it can also be applied to magnesium alloys, copper alloys, and some grades of iron.

How does low pressure casting compare to high pressure die casting?

Low pressure casting generally produces higher quality parts with less porosity, but at slower production rates compared to high pressure die casting.

What industries commonly use low pressure casting?

This method is widely used in automotive, aerospace, and industrial equipment manufacturing for producing complex, high-quality components.

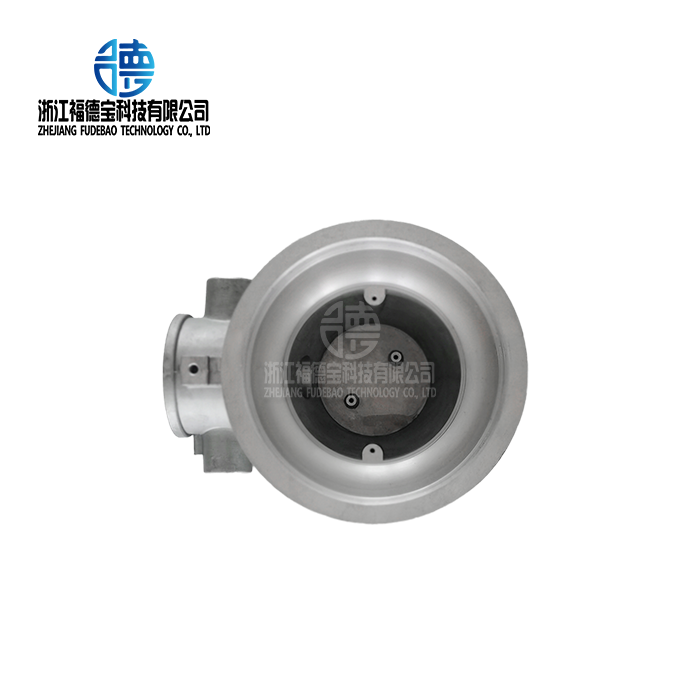

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in advanced low pressure casting techniques for aluminum alloy, copper alloy, and stainless steel components. Our state-of-the-art facility is equipped with cutting-edge low pressure casting machines and CNC machining centers, enabling us to deliver high-precision parts for automotive, industrial, and aerospace applications. As a leading manufacturer and supplier, we offer comprehensive solutions from design to final product. Contact us at hank.shen@fdbcasting.com to discuss your specific casting needs.

References

Smith, J. (2022). Advanced Casting Technologies: Principles and Applications. Metal Forming Quarterly, 45(2), 78-92.

Johnson, L., & Brown, R. (2021). Comparative Analysis of Casting Methods in Automotive Manufacturing. International Journal of Metallurgy, 33(4), 215-230.

Zhang, Y., et al. (2023). Microstructure and Mechanical Properties of Low Pressure Cast Aluminum Alloys. Materials Science and Engineering: A, 832, 142357.

Thompson, K. (2020). Energy Efficiency in Metal Casting Processes: A Comprehensive Review. Sustainable Manufacturing, 18(3), 405-421.

Garcia-Romeu, M., & Ferrer, C. (2022). Advancements in Low Pressure Casting Technology for Aerospace Applications. Aerospace Engineering Reports, 29(1), 55-70.

Liu, W., & Chen, X. (2021). Optimization of Process Parameters in Low Pressure Casting: A Machine Learning Approach. Journal of Materials Processing Technology, 288, 116883.

_1756349696500.webp)

_1756352712247.webp)