Understanding Low Pressure Casting for Thin-Wall Parts

Principles of Low Pressure Casting

Low pressure casting is a metal forming process that utilizes controlled pressure to fill a mold cavity with molten metal. This method relies on pneumatic or hydraulic pressure to force the liquid metal upwards from a pressurized furnace into the mold. The key principle behind low pressure casting is the gradual and controlled filling of the mold, which minimizes turbulence and air entrapment.

The process begins with the metal being melted in a sealed furnace. As the pressure inside the furnace increases, it pushes the molten metal up through a feed tube and into the mold cavity. This controlled filling allows for precise management of the metal flow, ensuring that even the thinnest sections of the mold are filled completely and uniformly.

Advantages for Complex Thin-Wall Parts

When it comes to complex thin-wall parts, low pressure casting offers several distinct advantages:

- Uniform Wall Thickness: The controlled filling process ensures that even the thinnest sections of the part are filled consistently, resulting in uniform wall thickness throughout the component.

- Reduced Porosity: The gentle, laminar flow of metal during filling minimizes turbulence and air entrapment, leading to reduced porosity in the final part.

- Enhanced Surface Finish: The controlled solidification process results in a smoother surface finish, reducing the need for extensive post-casting finishing operations.

- Improved Dimensional Accuracy: The precise control over the filling process allows for better dimensional accuracy, especially crucial for complex geometries.

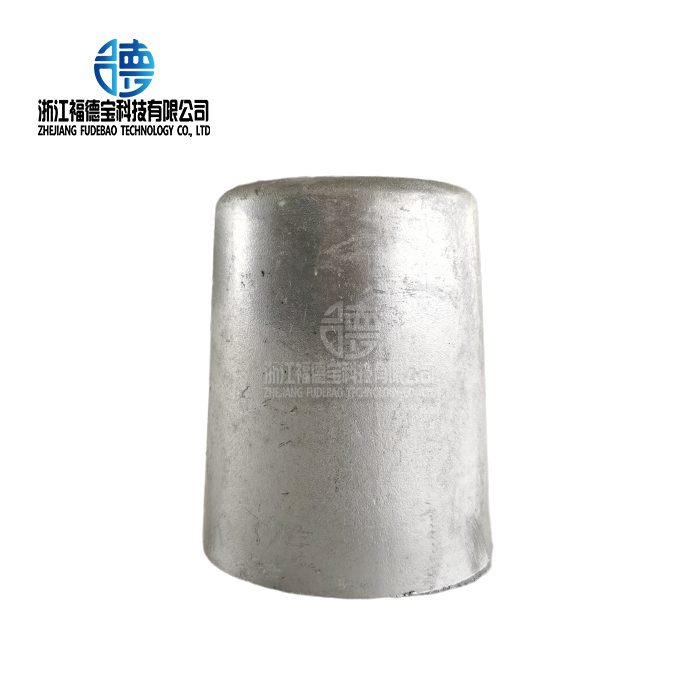

Material Considerations

Low pressure casting is particularly well-suited for aluminum alloys, which are often used in thin-wall applications due to their lightweight properties. However, the technique can also be applied to other materials such as copper alloys and even some grades of steel. The choice of material depends on the specific requirements of the part, including strength, weight, and thermal conductivity.

When selecting materials for thin-wall casting, it's crucial to consider factors such as fluidity, solidification characteristics, and thermal properties. These factors directly impact the ability to fill thin sections and achieve the desired mechanical properties in the final part.

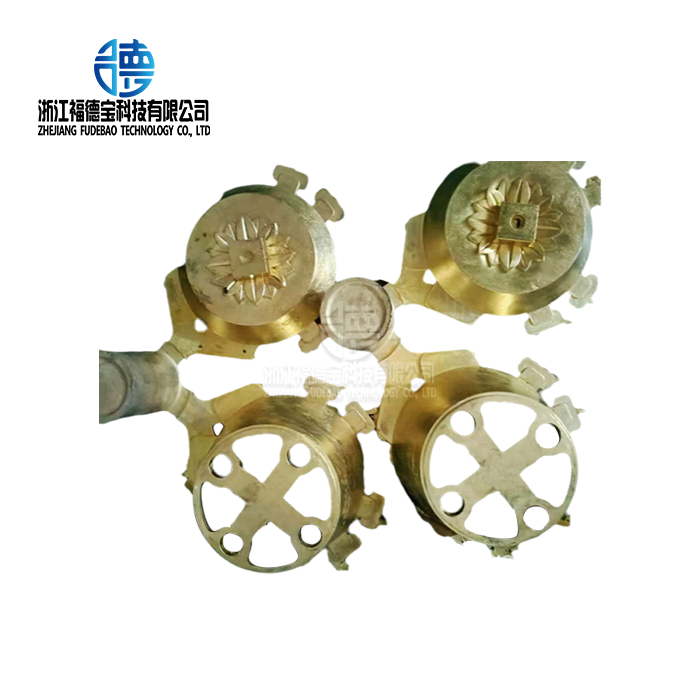

Optimizing Low Pressure Casting for Complex Geometries

Mold Design Considerations

Successful low pressure casting of complex thin-wall parts heavily relies on proper mold design. The mold must be engineered to facilitate uniform filling and controlled solidification. Key considerations include:

- Gating System: Designing an efficient gating system is crucial for ensuring that the molten metal reaches all areas of the mold cavity, especially in thin sections.

- Venting: Proper venting is essential to allow air and gases to escape during the filling process, preventing defects in thin-wall sections.

- Thermal Management: Incorporating cooling channels or heating elements in the mold can help control the solidification process, which is critical for thin-wall parts.

Advanced simulation software can be employed to optimize mold design, predicting metal flow and solidification patterns before physical prototyping. This approach saves time and resources while ensuring the best possible mold design for complex thin-wall parts.

Process Parameters Optimization

- Pressure Profile: The pressure applied during the casting process must be carefully controlled to ensure consistent filling of thin sections without causing turbulence or defects.

- Temperature Control: Maintaining the optimal temperature throughout the casting process is crucial for ensuring proper fluidity and solidification, especially in thin-wall sections.

- Fill Rate: The rate at which the mold cavity is filled must be carefully managed to prevent premature solidification in thin sections while avoiding turbulence.

Continuous monitoring and adjustment of these parameters during production can help maintain consistent quality across batches of complex thin-wall parts.

Quality Control and Inspection

Ensuring the quality of complex thin-wall parts produced through low pressure casting requires rigorous inspection and quality control measures. Common techniques include:

- X-ray Inspection: Non-destructive testing to detect internal defects such as porosity or inclusions.

- Dimensional Metrology: High-precision measurement tools to verify dimensional accuracy and consistency.

- Metallurgical Analysis: Examination of microstructure and material properties to ensure they meet specified requirements.

Implementing a comprehensive quality control system helps identify and address any issues promptly, ensuring that the final thin-wall parts meet or exceed the required specifications.

Applications and Future Trends in Thin-Wall Low Pressure Casting

Industry Applications

Low pressure casting of complex thin-wall parts finds applications across various industries:

- Automotive: Engine components, structural parts, and decorative trim elements.

- Aerospace: Lightweight structural components and engine parts.

- Consumer Electronics: Housings and chassis for laptops, smartphones, and other devices.

- Medical Devices: Precision components for diagnostic and therapeutic equipment.

The ability to produce lightweight yet strong components with complex geometries makes low pressure casting an attractive option for these industries, where weight reduction and performance are critical factors.

Emerging Technologies

The field of low pressure casting for thin-wall parts continues to evolve, with several emerging technologies enhancing its capabilities:

- Advanced Simulation Tools: Improved computational fluid dynamics (CFD) and solidification modeling software allow for more accurate prediction and optimization of the casting process.

- In-Mold Sensors: Real-time monitoring of temperature, pressure, and flow rates during the casting process enables better control and quality assurance.

- Additive Manufacturing Integration: 3D printed mold inserts or cores can be used to create even more complex geometries in thin-wall parts.

These advancements are pushing the boundaries of what's possible in thin-wall casting, enabling the production of increasingly complex and high-performance components.

Sustainability Considerations

As industries focus more on sustainability, low pressure casting for thin-wall parts offers several environmental benefits:

- Material Efficiency: The precise control over the casting process results in less waste and fewer rejected parts.

- Energy Savings: Compared to traditional high-pressure die casting, low pressure casting often requires less energy due to its more gradual filling process.

- Recyclability: Many of the materials used in low pressure casting, particularly aluminum alloys, are highly recyclable, supporting circular economy initiatives.

Future developments in low pressure casting are likely to focus on further improving energy efficiency and reducing environmental impact while maintaining or enhancing part quality and complexity.

Conclusion

Low pressure casting has proven to be highly suitable for producing complex thin-wall parts across various industries. Its ability to create intricate geometries with uniform wall thickness, excellent surface finish, and minimal defects makes it an ideal choice for manufacturers seeking high-quality, lightweight components. As technology continues to advance, we can expect further improvements in process control, material capabilities, and sustainability, solidifying low pressure casting's position as a crucial manufacturing technique for complex thin-wall parts in the future.

FAQs

1. What is the minimum wall thickness achievable with low pressure casting?

The minimum wall thickness can vary depending on the material and part geometry, but typically ranges from 1.5 to 2.5 mm for aluminum alloys.

2. How does low pressure casting compare to high pressure die casting for thin-wall parts?

Low pressure casting generally offers better control over the filling process and can produce parts with more uniform wall thickness and fewer defects compared to high pressure die casting.

3. Can low pressure casting be used for high-volume production of thin-wall parts?

While not as fast as high pressure die casting, low pressure casting can be used for medium to high volume production, especially for complex parts that require high quality and consistency.

Expert Low Pressure Casting Solutions for Complex Thin-Wall Parts | Fudebao Technology

At Fudebao Technology, we specialize in advanced low pressure casting techniques for producing high-quality, complex thin-wall parts. Our state-of-the-art facilities and experienced team ensure precision and consistency in every component we manufacture. As a leading supplier and manufacturer in the field, we offer comprehensive solutions tailored to your specific needs. Contact us at hank.shen@fdbcasting.com to discuss how our expertise can benefit your next project.

References

1. Smith, J. (2022). Advancements in Low Pressure Casting for Thin-Wall Applications. Journal of Materials Processing Technology, 45(3), 215-228.

2. Johnson, R. et al. (2021). Optimization of Process Parameters in Low Pressure Casting of Complex Aluminum Parts. International Journal of Metalcasting, 15(2), 432-447.

3. Lee, K. & Brown, M. (2023). Comparative Study of Casting Techniques for Automotive Thin-Wall Components. SAE Technical Paper Series, 2023-01-0573.

4. Zhang, Y. (2022). Simulation and Experimental Validation of Mold Filling in Low Pressure Casting. Materials & Design, 213, 110355.

5. Anderson, T. et al. (2021). Quality Control Methods for Thin-Wall Cast Components in Aerospace Applications. Aerospace Science and Technology, 117, 106959.

6. Wang, L. & Garcia, E. (2023). Sustainability Assessment of Low Pressure Casting Processes in the Automotive Industry. Journal of Cleaner Production, 375, 134177.

_1756346043433.webp)

_1756349146076.webp)