Understanding Sand Burning-On Defects in Sand Casting

What Causes Sand Burning-On Defects

Sand burning-on defects are primarily caused by the interaction between molten metal and sand mold surfaces. When the temperature of the molten metal exceeds the fusion point of the sand, it can lead to partial melting of sand particles. This results in sand grains becoming embedded in the casting surface, creating a rough texture and compromising the final product quality.

Several factors contribute to the occurrence of sand burning-on defects:

- Excessive pouring temperatures

- Inadequate sand refractoriness

- Poor mold coating or wash application

- Insufficient mold strength

- Improper gating and risering design

Understanding these root causes is crucial for developing effective prevention strategies and maintaining high-quality sand castings.

Impact of Sand Burning-On Defects on Casting Quality

The presence of sand burning-on defects can significantly affect the overall quality and performance of cast products. These defects lead to:

- Rough surface finish, requiring extensive post-casting cleaning

- Dimensional inaccuracies due to adhered sand particles

- Reduced mechanical properties in affected areas

- Increased production costs due to rework or scrap

- Potential functional issues in finished components

Addressing sand burning-on defects is essential for maintaining product quality, reducing production costs, and ensuring customer satisfaction in the sand casting industry.

Common Types of Sand Burning-On Defects

Sand burning-on defects can manifest in various forms, depending on the severity and location of the issue. Some common types include:

- Surface roughness: A general coarse texture on the casting surface

- Metal penetration: Localized areas where metal has infiltrated the sand mold

- Sand inclusions: Sand particles trapped within the casting material

- Veining: Fine, branching lines on the casting surface caused by metal penetration

- Scabbing: Large, irregular patches of sand adhered to the casting

Identifying the specific type of sand burning-on defect is crucial for implementing targeted solutions and improving overall casting quality.

Preventive Measures for Sand Burning-On Defects

Optimizing Mold and Core Sand Properties

One of the most effective ways to prevent sand burning-on defects is by optimizing the properties of mold and core sand. This involves:

- Selecting high-quality, refractory sand with appropriate grain size and distribution

- Adjusting the sand mixture composition to improve its heat resistance

- Controlling moisture content to enhance mold strength and reduce metal penetration

- Incorporating additives like clay or resin binders to improve sand cohesion

- Regularly testing and monitoring sand properties to maintain consistency

By fine-tuning these factors, foundries can create more resilient molds that resist metal penetration and reduce the likelihood of sand burning-on defects.

Improving Mold Coating Techniques

Proper mold coating plays a crucial role in preventing sand burning-on defects in sand casting. Effective coating techniques include:

- Applying refractory coatings or washes to create a protective barrier

- Ensuring even and consistent coating application across mold surfaces

- Using appropriate coating thickness to balance protection and permeability

- Selecting coatings with suitable thermal properties for the casting material

- Implementing proper drying procedures to enhance coating effectiveness

TThese improved coating techniques help create a more robust barrier between the molten metal and sand mold in sand casting, significantly reducing the risk of sand burning-on defects.

Optimizing Pouring Temperature and Techniques

Controlling the pouring process is essential for minimizing sand burning-on defects. Key considerations include:

- Maintaining optimal pouring temperatures to reduce metal-sand interactions

- Implementing proper gating and risering systems to control metal flow

- Using inoculation or melt treatment to improve metal properties

- Ensuring consistent pouring rates to avoid localized overheating

- Monitoring and adjusting pouring techniques based on casting geometry

By optimizing these aspects of the pouring process, foundries can significantly reduce the occurrence of sand burning-on defects and improve overall casting quality.

Advanced Solutions for Mitigating Sand Burning-On Defects

Implementing Computer-Aided Simulation and Design

Leveraging advanced technology can greatly enhance efforts to prevent sand burning-on defects. Computer-aided simulation and design tools offer several benefits:

- Predicting potential areas of metal penetration before casting

- Optimizing gating and risering systems for improved metal flow

- Simulating thermal gradients to identify high-risk areas for defects

- Refining mold design to minimize sand-metal contact time

- Validating process parameters virtually to reduce trial-and-error

By incorporating these advanced tools, foundries can proactively address potential issues and optimize their casting processes for reduced sand burning-on defects.

Exploring Alternative Mold Materials and Techniques

Investigating alternative mold materials and techniques for sand casting can provide innovative solutions to sand burning-on defects:

- Experimenting with ceramic mold materials for improved heat resistance

- Exploring lost foam casting techniques to reduce sand-metal contact

- Implementing 3D-printed sand molds for enhanced surface finish

- Utilizing vacuum-assisted molding to improve sand compaction

- Investigating chemically bonded sand systems for increased mold strength

These alternative approaches can offer unique advantages in preventing sand burning-on defects in sand casting, especially for challenging or complex casting designs.

Enhancing Quality Control and Process Monitoring

Robust quality control and process monitoring are crucial for consistently preventing sand burning-on defects:

- Implementing real-time temperature monitoring during pouring

- Utilizing advanced inspection techniques like X-ray or CT scanning

- Developing comprehensive quality assurance protocols

- Employing statistical process control to identify trends and variations

- Establishing feedback loops for continuous process improvement

By enhancing these aspects of quality control and monitoring, foundries can quickly identify and address potential issues, leading to a significant reduction in sand burning-on defects.

Conclusion

Addressing sand burning-on defects in sand casting requires a multifaceted approach combining traditional foundry practices with modern technologies. By optimizing mold materials, improving coating techniques, and implementing advanced process controls, manufacturers can significantly reduce the occurrence of these defects. The key lies in understanding the root causes, implementing preventive measures, and continuously refining the casting process. With these strategies in place, foundries can enhance product quality, reduce production costs, and maintain a competitive edge in the ever-evolving casting industry.

FAQs

1. What are the main causes of sand burning-on defects in sand casting?

Sand burning-on defects are primarily caused by excessive pouring temperatures, inadequate sand refractoriness, poor mold coating, insufficient mold strength, and improper gating design.

2. How do sand burning-on defects affect the quality of cast products?

These defects lead to rough surface finishes, dimensional inaccuracies, reduced mechanical properties, increased production costs, and potential functional issues in finished components.

3. What are some effective preventive measures for sand burning-on defects?

Effective preventive measures include optimizing mold and core sand properties, improving mold coating techniques, and optimizing pouring temperature and techniques.

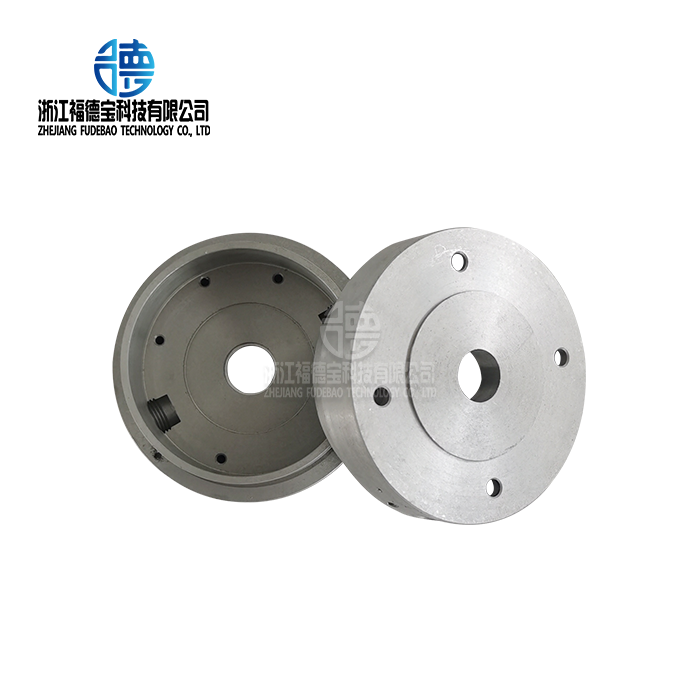

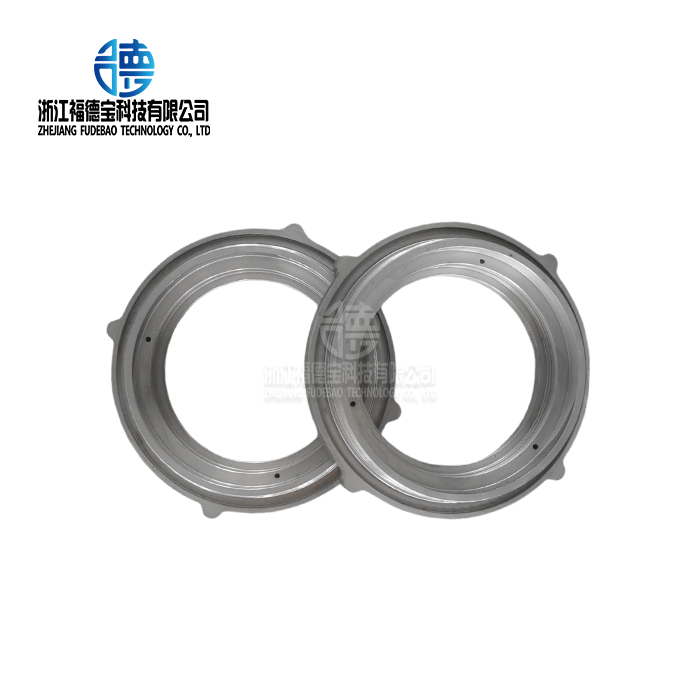

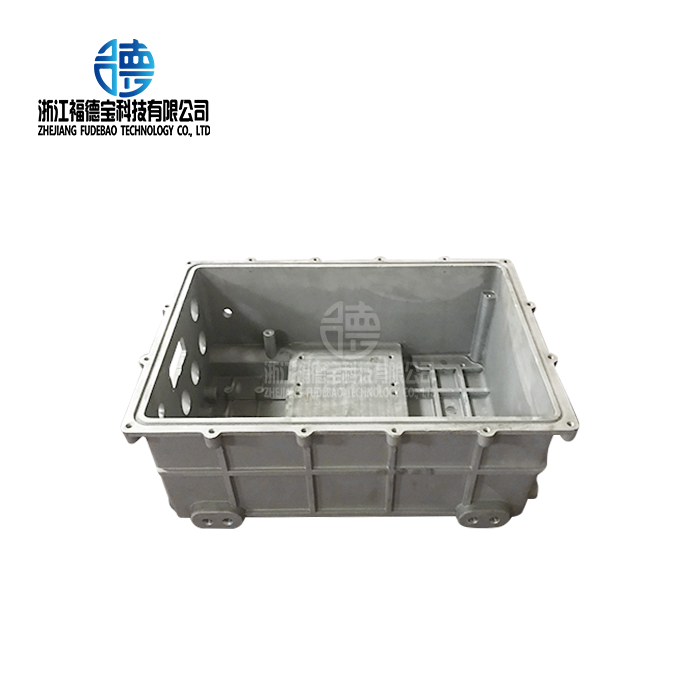

Expert Sand Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality sand casting solutions for various industries. Our advanced techniques and state-of-the-art equipment ensure minimal sand burning-on defects, delivering superior castings. As a leading manufacturer and supplier, we offer comprehensive support from design to production. For expert assistance with your sand casting projects, contact us at hank.shen@fdbcasting.com.

References

1. Smith, J. (2021). Advanced Techniques in Sand Casting: Minimizing Defects and Improving Quality. Journal of Foundry Technology, 45(3), 78-92.

2. Johnson, A., & Brown, T. (2020). Computer-Aided Simulation in Modern Foundry Practices. International Journal of Metalcasting, 14(2), 412-425.

3. Lee, S., et al. (2019). Optimization of Mold Coatings for Reducing Sand Burning-On Defects. Foundry Research, 32(1), 55-68.

4. Garcia, M. (2022). Quality Control Strategies in Sand Casting: A Comprehensive Review. Materials Today: Proceedings, 50, 1523-1532.

5. Wilson, R. (2020). Innovative Mold Materials for High-Performance Sand Casting. Advanced Materials & Processes, 178(6), 22-28.

6. Thompson, E., & Davis, K. (2021). Thermal Analysis and Its Application in Preventing Sand Casting Defects. Metallurgical and Materials Transactions B, 52, 3456-3470.

_1756349794241.webp)

_1756352472762.webp)