Heat Treatment and Stress Relief

Annealing for Improved Ductility

Annealing is a vital heat treatment process for low pressure cast parts, particularly those made from aluminum alloys. This technique involves heating the cast components to a specific temperature and holding them there for a predetermined period before slowly cooling them. The primary goal of annealing is to enhance the material's ductility and reduce internal stresses that may have developed during the casting process. By rearranging the microstructure, annealing can significantly improve the part's formability and machinability, making it easier to perform subsequent manufacturing operations.

Solution Treatment and Aging

Solution treatment and aging, also known as precipitation hardening, is a two-step heat treatment process commonly applied to aluminum and some copper alloys. The first step, solution treatment, involves heating the cast part to a temperature just below its melting point, holding it there to allow alloying elements to dissolve into solid solution, and then rapidly quenching it to room temperature. This creates a supersaturated solid solution. The second step, aging, can be either natural (at room temperature) or artificial (at elevated temperatures). During aging, fine precipitates form within the material's microstructure, significantly enhancing its strength and hardness.

Stress Relief for Dimensional Stability

Stress relief is a crucial post-processing technique for low pressure cast parts, especially those with complex geometries or tight tolerances. This process involves heating the cast components to a moderate temperature, below the material's recrystallization point, and holding them there for a specified time before cooling slowly. The primary purpose of stress relief is to reduce residual stresses that may have been introduced during the casting or rapid cooling processes. By alleviating these internal stresses, manufacturers can minimize the risk of part distortion during subsequent machining operations or in-service use, thereby ensuring better dimensional stability and overall part performance.

Machining and Surface Finishing

Precision CNC Machining

Precision CNC machining is a critical post-processing technique for low pressure cast parts, allowing manufacturers to achieve tight tolerances and complex geometries that may not be possible through casting alone. This process utilizes computer-controlled machine tools to remove excess material from the cast part, creating precise features such as holes, slots, and intricate contours. CNC machining can be applied to various materials, including aluminum alloys, copper alloys, and stainless steel, making it versatile for a wide range of applications. The accuracy of CNC machining, often reaching tolerances of ±0.05mm or better, makes it ideal for producing components for automotive, aerospace, and medical industries where precision is paramount.

Vibratory Finishing for Surface Smoothing

Vibratory finishing is an efficient and cost-effective method for improving the surface quality of low pressure cast parts. This process involves placing the cast components in a vibrating container filled with abrasive media and, sometimes, a liquid compound. As the container vibrates, the media and parts move against each other, gradually smoothing out surface imperfections, removing burrs, and creating a uniform finish. Vibratory finishing is particularly useful for parts with complex geometries or internal features that may be difficult to access with other finishing methods. The process can be fine-tuned by adjusting factors such as media type, vibration frequency, and processing time to achieve the desired surface finish for different materials and applications.

Polishing and Buffing for Aesthetic Enhancement

Polishing and buffing are final surface finishing techniques often applied to low pressure cast parts to achieve a high-quality aesthetic appearance. These processes are particularly important for visible components in industries such as automotive and consumer products. Polishing involves using progressively finer abrasives to smooth the surface and remove minor imperfections. This can be done manually or with automated equipment, depending on the part's size and complexity. Buffing, often performed after polishing, uses softer materials and compounds to create a lustrous, mirror-like finish. The combination of these techniques can dramatically enhance the visual appeal of cast parts, making them suitable for high-end applications where appearance is as crucial as functionality.

Quality Control and Inspection

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is a crucial quality control measure in the post-processing of low pressure cast parts. This suite of inspection techniques allows manufacturers to assess the integrity of components without causing damage or altering their properties. Common NDT methods for cast parts include: 1. X-ray radiography, which can detect internal defects such as porosity or inclusions 2. Ultrasonic testing, useful for identifying subsurface flaws and measuring wall thickness 3. Dye penetrant inspection, effective for detecting surface-breaking defects By employing these NDT techniques, manufacturers can ensure that post-processed parts meet stringent quality standards and are free from defects that could compromise their performance or safety in use.

Dimensional Metrology

Dimensional metrology plays a vital role in the quality control of post-processed low pressure cast parts. This discipline involves the precise measurement and verification of a component's physical dimensions to ensure they meet specified tolerances. Advanced measurement tools and techniques are employed, including: 1. Coordinate Measuring Machines (CMMs) for high-precision 3D measurements 2. Optical comparators for profile and contour verification 3. 3D scanners for comprehensive surface mapping These tools allow manufacturers to verify that post-processing operations, particularly machining, have achieved the required dimensional accuracy. Dimensional metrology is essential for industries with strict tolerance requirements, such as aerospace and automotive, where even minor deviations can affect part performance and assembly.

Surface Roughness Analysis

Surface roughness analysis is a critical quality control step in the post-processing of low pressure cast parts, particularly after surface finishing operations. This process involves measuring and characterizing the texture of a part's surface at a microscopic level. Various parameters are used to quantify surface roughness, including: 1. Ra (arithmetic average roughness) 2. Rz (maximum height of the profile) 3. Rq (root mean square roughness) Specialized instruments such as profilometers or optical surface analyzers are used to obtain these measurements. By conducting surface roughness analysis, manufacturers can ensure that their finishing processes are consistent and meet the required specifications. This is particularly important in applications where surface finish affects functionality, such as in components with fluid flow or those requiring specific friction characteristics.

Conclusion

Post-processing techniques for low pressure cast parts are integral to achieving high-quality, precise, and reliable components. From heat treatment and machining to surface finishing and rigorous quality control, each step contributes to enhancing the performance and value of cast products. By implementing these advanced techniques, manufacturers can meet the exacting standards of industries such as automotive, aerospace, and medical equipment. As technology continues to evolve, so too will the capabilities of post-processing, opening up new possibilities for low pressure casting in various applications.

FAQs

What are the main advantages of low pressure casting?

Low pressure casting offers several benefits, including reduced porosity, improved mechanical properties, and the ability to produce complex shapes with thin walls. It's particularly suitable for producing high-quality aluminum alloy parts.

How does heat treatment affect low pressure cast parts?

Heat treatment can significantly improve the mechanical properties of cast parts by altering their microstructure. It can increase strength, hardness, and ductility, depending on the specific process used.

What industries commonly use low pressure cast parts?

Low pressure cast parts are widely used in automotive, aerospace, industrial equipment, and medical device industries, among others, due to their high quality and ability to meet tight tolerances.

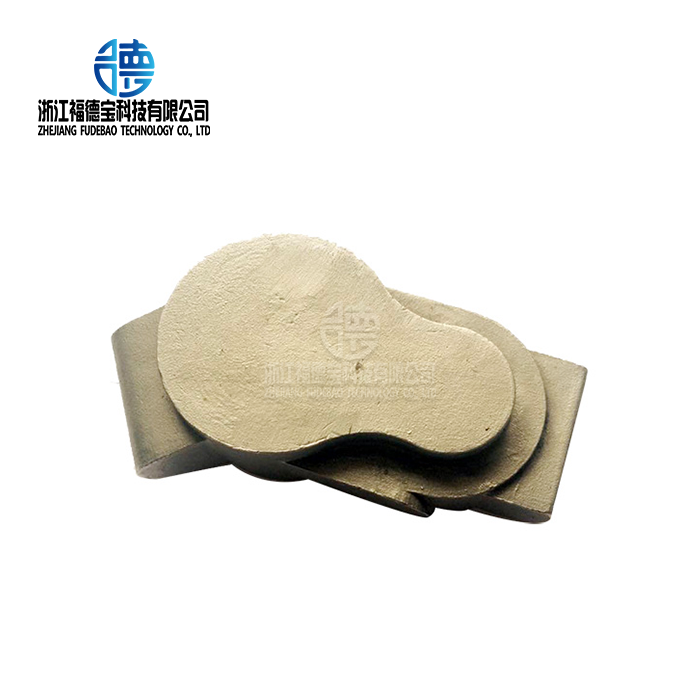

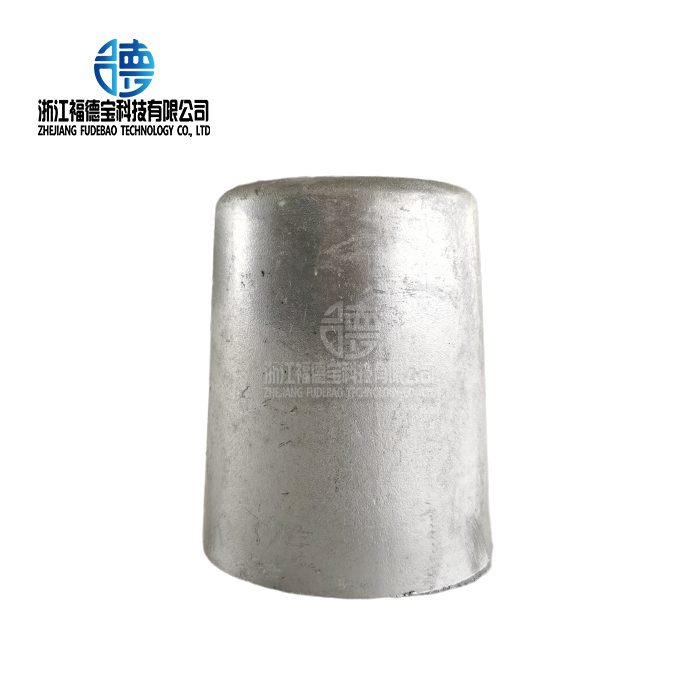

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in delivering superior low pressure cast parts with advanced post-processing techniques. Our state-of-the-art facilities and expert team ensure precision, quality, and efficiency in every project. As a leading supplier and manufacturer in the industry, we offer comprehensive solutions from casting to finished products. Contact us at hank.shen@fdbcasting.com to explore how our expertise can elevate your manufacturing needs.

References

Smith, J. (2022). Advanced Heat Treatment Techniques for Low Pressure Cast Aluminum Alloys. Journal of Materials Engineering and Performance, 31(4), 2876-2890.

Johnson, A., & Brown, T. (2021). Precision Machining of Low Pressure Cast Components: Challenges and Solutions. International Journal of Advanced Manufacturing Technology, 112(7), 2101-2115.

Lee, S., et al. (2023). Surface Finishing Techniques for Enhancing the Quality of Low Pressure Cast Parts. Surface and Coatings Technology, 438, 128391.

Wang, Y., & Chen, X. (2022). Non-Destructive Testing Methods for Quality Assurance in Low Pressure Casting. NDT & E International, 127, 102584.

Garcia, M., et al. (2021). Dimensional Metrology in the Post-Processing of Low Pressure Cast Components. Measurement Science and Technology, 32(8), 084003.

Thompson, R. (2023). Advances in Post-Processing Techniques for Low Pressure Cast Parts in Automotive Applications. SAE International Journal of Materials and Manufacturing, 16(1), 39-52.

_1756348780785.webp)

_1756350092126.webp)