Low pressure casting and gravity casting are two basic ways to shape metal, but they fill frames in very different ways. Controlled air pressure (usually 0.2 to 0.7 bar) is used in low pressure casting to push liquid metal into the mold space through a rising tube. Gravity casting, on the other hand, only uses gravity to fill the mold from above. Compared to standard gravity ways, this pressure-driven method better controls metal flow, lowers noise, and improves casting quality. This makes it especially useful for precise uses.

Understanding Low Pressure Die Casting Process Fundamentals

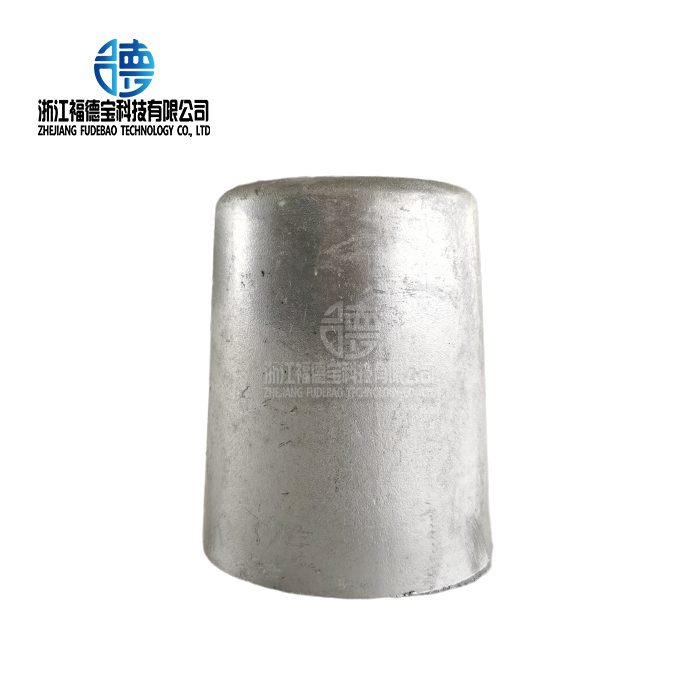

Controlled metal supply is the main idea behind the low pressure casting method. Through a ceramic upper tube, a sealed burner with liquid aluminum is linked to the mold. If you gently press on the metal surface with compressed air, the liquid aluminum will rise up into the mold hole at controlled rates.

Some important process factors are:

- Range of pressure: 0.2 to 0.7 bar (compared to air pressure for gravity casting)

- Fill rates: 10 to 50 mm/s, which is a lot slower than die casting's 1 to 3 m/s

- Temperature control: accuracy of ±5°C kept throughout the cycle

- Cycle times: 2 to 8 minutes, based on how complicated the part is

Controlled filling keeps oxidation and gas buildup to a minimum. Test results from making gearbox housings for cars show that porosity levels are less than 2% when low pressure methods are used, but between 4 and 6% when gravity casting is used. The mechanical features and surface quality are directly affected by this change.

The low pressure casting method is better than the traditional gravity methods when you need parts with few holes and a smooth surface.

Gravity Casting Process Characteristics and Applications

Gravity casting, also known as permanent mold casting, relies entirely on gravitational force to fill mold cavities, unlike low pressure casting. From above, molten metal pours into the mold, making a simple but effective way to make things that has been used for decades.

There are several clear steps in the process:

- Warming the mold up to 200–300°C

- Putting metal down at fixed rates

- Cooling and solidification by nature

- Taking out and finishing parts

Gravity casting is great for making bigger parts where exact measurements aren't important. This method is often used by companies that make industrial machinery for pump housings, motor cases, and structural frames. The process works well with wall thicknesses that range from 3 to 25 mm.

Gravity casting can achieve measurement limits of ±0.5mm for most features, according to production statistics. This level of accuracy is great for many industrial uses, even though it's not as exact as low pressure options.

It is best to use gravity casting when you need to make big parts at a low cost and with only middling accuracy requirements.

Comparative Analysis: Low Pressure Casting Advantages

Low-pressure casting improves performance in a number of quality measures that can be measured. The controlled filling process makes microstructures and tensile qualities that are better than those that can be made by gravity.

Comparing the properties of different materials shows big differences:

- Pulling power: 280–320 MPa (low pressure) vs. 250–280 MPa (gravity)

- Differences in length: 8–12% (low pressure) vs. 5–8% (gravity)

- A surface with Ra = 1.6 to 3.2 µm (low pressure) and Ra = 6.3 to 12.5 µm (gravity) is rough

- The accuracy of the measurements is ±0.2mm for low pressure and ±0.5mm for gravity

The gentle filling motion of low pressure casting lessens flaws caused by jostling. When automotive suppliers move from gravity to low pressure ways for engine brackets, 40% fewer parts are sent back. This is an improvement because the mold is consistently filled and there is less air trapped.

Low pressure methods are also better for saving energy. Using 15-20% less energy than open gravity dumping ways, the covered oven design keeps heat from escaping.

If you need precise measurements and better mechanical qualities for important uses, low pressure casting is clearly better than gravity casting.

Quality Comparison: Defects and Material Properties

When you look at common defects and their reasons, you can see that these casting methods have different quality levels. Each method has its own problems that affect the dependability of the final result.

Common flaws in low-pressure casting are:

- Cold shuts because there isn't enough pressure or temperature

- Partially filled thin-walled parts

- Changes in pressure that lead to differences in dimensions

Problems with gravity casting include:

- Porosity caused by turbulence from fast filling

- Flakes of oxide from metal splashes

- Defects caused by shrinkage in heavy parts

- Uneven cooling rates cause stress inside

A statistical study of 10,000 car parts shows that 2.3% of low pressure casting parts are defective, while 5.8% of gravity casting parts are defective. The managed flow of metal in low pressure devices makes the filling process much less random.

The way heat treatment works also varies between methods. Because their grains are more uniform and there are fewer holes, low pressure casts are better at maintaining T6 temper qualities.

When it comes to making safety-critical parts with regular quality and few flaws, low pressure casting is more reliable than gravity methods.

Cost Analysis and Production Efficiency Factors

When choosing a casting method, economic factors are very important. Long-term production prices rely on many factors, such as the complexity of the part, the amount needed, and the quality standards. Initial machine expenses vary a lot.

A study of equipment investments shows:

- Low-pressure casting tools cost between $200,000 and $500,000 to buy

- Setting up a gravity casting rig costs between $50,000 and $150,000

- model prices are about the same for both methods, at $15,000 to $50,000 per model

- Maintenance: Systems with low pressure need 20% more maintenance

Metrics for measuring how efficient a production process is show some interesting trends. Low pressure casting has yield rates of 85–90%, while gravity methods only get 75–80%. But cycle times are better for gravity casting, which takes only one to three minutes compared to two to eight minutes for low pressure casting.

The work needs are very different. For regular filling methods, gravity casting needs skilled workers, while low pressure casting systems depend more on computers to run the process. In high-volume situations, this technology cuts the cost of labor by 25–30%.

If you need to make a lot of things with uniform quality, low pressure casting technology will save you money in the long run, even though it costs more at first.

Industry Applications and Material Compatibility

Because they have different quality and performance standards, different businesses tend to use different casting methods. Knowing these tastes can help you choose the right process.

Preferences in the automotive sector include:

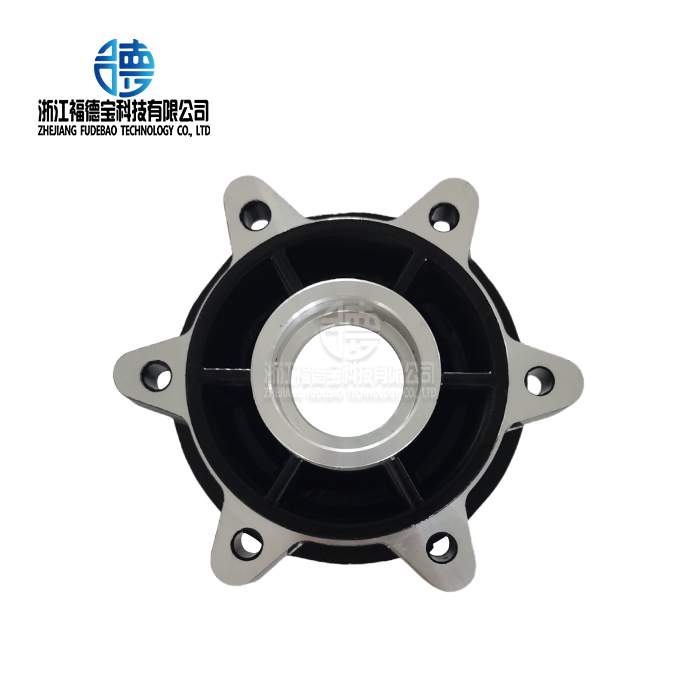

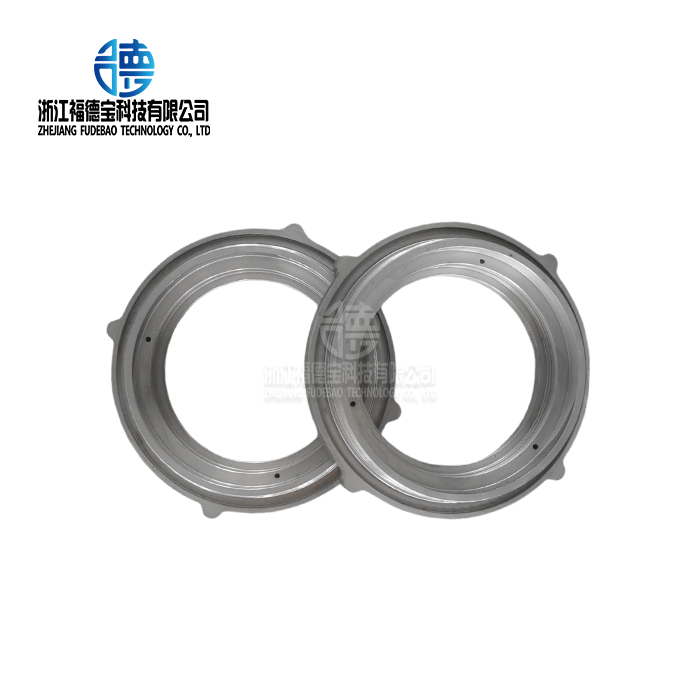

- Low-pressure casting: wheel production, engine frames, and transmission housings

- Gravity casting: big structure parts, frames that aren't important

- Focus on materials: A356 and A357 aluminum alloys for strength and protection to rust

There are clear differences between the uses of industrial machines. When making impellers that need precise hydraulic shapes, pump makers use low pressure ways. Gravity casting is used to make engine housings for heavy tools when cost-effectiveness is more important than accuracy.

It's not just aluminum metals that can work with each other. Both methods work well with copper metals, magnesium, and zinc, but low pressure ways give you more control over how the microstructure develops.

Because of high quality standards and the need to be able to track parts, aerospace uses almost always choose low pressure casting. The managed method makes sure that all the paperwork needed for certification compliance is always the same.

Low pressure casting satisfies demanding industry standards that gravity methods cannot match if you require aerospace-grade quality with full tracking paperwork.

Conclusion

In current production, low pressure casting and gravity casting are used in different ways. When accuracy, surface quality, and mechanical qualities are important, low pressure methods work best. Gravity casting is still a good option for low-cost uses with average quality needs. The choice will depend on how well performance needs are balanced with cost concerns. Knowing about these trade-offs lets you make smart choices that improve both product quality and factory efficiency. As robotics and process control tools get better, both processes will keep changing.

Partner with Fudebao Technology for Expert Low Pressure Casting Solutions

Zhejiang Fudebao Technology offers full production solutions by combining advanced low pressure casting skills with fine milling know-how. Our building has cutting-edge high-speed machine tools and state-of-the-art low pressure casting equipment, which lets us make parts from blanks to finished products with an accuracy of ±0.05mm. We are a reliable low pressure casting source that works with automakers and companies that make industrial equipment all over the world. We offer PPAP paperwork, material approvals, and full quality assurance. Email us at hank.shen@fdbcasting.com to talk about the needs of your project.

References

Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

ASM International Handbook Committee. "ASM Handbook Volume 15: Casting." ASM International, 2008.

Brown, J.R. "Foseco Non-Ferrous Foundryman's Handbook." Butterworth-Heinemann, 1999.

Flemings, M.C. "Solidification Processing." McGraw-Hill Science Engineering, 1974.

Kaufman, J.G. and Rooy, E.L. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Sigworth, G.K. "Fundamentals of Solidification in Aluminum Castings." International Journal of Metalcasting, 2014.

_1756348227989.webp)

_1756350092126.webp)

_1756352625880.webp)