Importance of Quality Control in CNC Machining Outsourcing

Understanding the Role of Quality Control

Quality control plays a crucial role in CNC machining outsourcing, ensuring that the final products meet the required specifications and standards. It involves a systematic approach to monitoring and evaluating various aspects of the manufacturing process, from raw material selection to final inspection. By implementing robust quality control measures, companies can minimize defects, reduce waste, and maintain consistency in their outsourced CNC machining projects.

Benefits of Effective Quality Control

Implementing effective quality control measures in CNC machining outsourcing offers numerous benefits. Firstly, it helps maintain product consistency, ensuring that each part produced meets the same high standards. This consistency is crucial for industries such as automotive and aerospace, where precision and reliability are paramount. Secondly, quality control helps reduce costs by identifying and addressing issues early in the production process, preventing costly rework or product recalls. Lastly, it enhances customer satisfaction by delivering high-quality parts that meet or exceed expectations.

Challenges in Quality Control for Outsourced CNC Machining

While quality control is essential, it can present challenges in outsourced CNC machining. One significant challenge is maintaining consistent communication with the outsourcing partner, especially when dealing with different time zones or language barriers. Another challenge is ensuring that the outsourcing partner adheres to the same quality standards and procedures as your in-house operations. Additionally, monitoring the production process remotely can be difficult, requiring robust reporting systems and periodic on-site audits to maintain quality assurance.

Essential Elements of Quality Control in CNC Machining

Establishing Clear Communication Channels

Clear communication is the foundation of successful quality control in CNC machining outsourcing. It's essential to establish open and efficient communication channels with your outsourcing partner. This includes regular meetings, progress reports, and a designated point of contact for addressing any issues or concerns. Utilizing collaboration tools and project management software can facilitate real-time communication and document sharing, ensuring that all parties are on the same page regarding quality requirements and project timelines.

Implementing Robust Inspection Procedures

Robust inspection procedures are crucial for maintaining quality control in CNC machining. This involves implementing a multi-stage inspection process that covers incoming materials, in-process checks, and final product inspection. Utilize advanced measurement tools such as coordinate measuring machines (CMMs) and optical comparators to ensure dimensional accuracy. Develop clear inspection criteria and checklists based on your product specifications, and train inspectors to consistently apply these standards. Regular calibration of measurement equipment is also essential to maintain accuracy and reliability in the inspection process.

Selecting a Reputable Supplier

Choosing the right supplier is critical for maintaining quality control in outsourced CNC machining. Look for suppliers with a proven track record in your industry, advanced equipment, and skilled operators. Consider factors such as their quality certifications (e.g., ISO 9001), experience with similar projects, and capacity to handle your production volume. Request sample parts or conduct a trial run to assess their capabilities before committing to a long-term partnership. Additionally, evaluate their quality control processes, including their inspection methods and documentation procedures, to ensure they align with your quality standards.

Strategies for Enhancing Quality Control in Outsourced CNC Machining

Developing a Comprehensive Quality Control Plan

A comprehensive quality control plan is essential for maintaining high standards in outsourced CNC machining. Start by clearly defining your quality objectives and requirements, including dimensional tolerances, surface finish specifications, and material properties. Develop detailed process control procedures that cover each stage of production, from material selection to final inspection. Include specific quality checkpoints throughout the manufacturing process and establish protocols for handling non-conforming parts. Regularly review and update your quality control plan to address any new challenges or changes in production requirements.

Leveraging Technology for Quality Assurance

Embracing technology can significantly enhance quality control efforts in CNC machining outsourcing. Implement computer-aided inspection (CAI) systems that integrate with your CAD/CAM software to streamline the inspection process and improve accuracy. Utilize statistical process control (SPC) software to analyze production data and identify trends or potential issues before they become significant problems. Consider implementing IoT-enabled sensors on CNC machines to monitor key parameters in real-time, allowing for proactive maintenance and quality control measures.

Continuous Improvement and Supplier Collaboration

Fostering a culture of continuous improvement is crucial for long-term success in quality control. Regularly analyze quality data and production metrics to identify areas for improvement. Conduct periodic audits of your outsourcing partner's facilities and processes to ensure ongoing compliance with quality standards. Encourage open dialogue with your supplier to address any quality concerns and collaborate on process improvements. Consider implementing a supplier development program to help your outsourcing partner enhance their capabilities and align more closely with your quality expectations.

Conclusion

Effective quality control is essential for successful CNC machining outsourcing. By focusing on clear communication, robust inspection procedures, and selecting reputable suppliers, companies can ensure the production of high-quality parts that meet their specifications. Developing a comprehensive quality control plan, leveraging technology, and fostering continuous improvement are key strategies for enhancing quality assurance in outsourced CNC machining projects. By implementing these key points, businesses can maintain consistency, reduce costs, and ultimately gain a competitive edge in their respective industries.

FAQs

1. What are the most critical factors in quality control for CNC machining?

The most critical factors include clear communication, robust inspection procedures, and selecting a reputable supplier. Additionally, implementing a comprehensive quality control plan and leveraging technology for quality assurance are essential.

2. How often should quality control audits be conducted?

The frequency of quality control audits depends on the complexity of the parts and production volume. Generally, it's recommended to conduct regular audits, at least quarterly, and more frequently during the initial stages of a new outsourcing relationship.

3. What certifications should I look for in a CNC machining supplier?

Look for suppliers with ISO 9001 certification, which demonstrates a commitment to quality management. Industry-specific certifications, such as AS9100 for aerospace or IATF 16949 for automotive, may also be relevant depending on your sector.

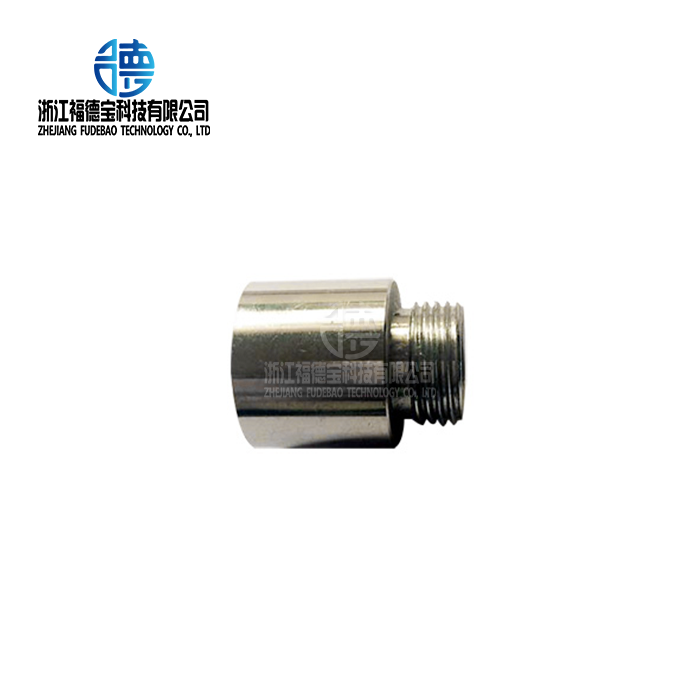

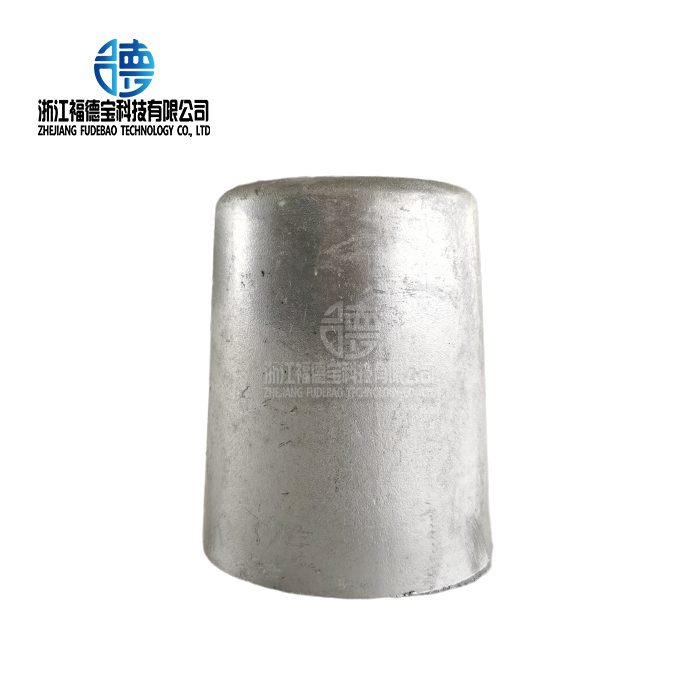

Expert CNC Machining Quality Control | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining with a focus on stringent quality control measures. Our state-of-the-art facilities and experienced team ensure top-notch quality for all your CNC machining needs. As a leading supplier and manufacturer, we offer comprehensive solutions from prototyping to high-volume production. Contact us at hank.shen@fdbcasting.com to learn how we can elevate your CNC machining projects with our expert quality control processes.

References

1. Smith, J. (2022). "Quality Control Strategies in CNC Machining". Journal of Manufacturing Technology, 45(2), 112-128.

2. Johnson, A. et al. (2021). "Implementing Effective Quality Control in Outsourced Manufacturing". International Journal of Production Research, 59(8), 2345-2360.

3. Brown, R. (2023). "Advanced Inspection Techniques for CNC Machined Parts". Quality Progress, 56(3), 78-92.

4. Lee, S. and Kim, H. (2022). "The Role of Supplier Selection in Quality Management for Outsourced CNC Machining". Supply Chain Management: An International Journal, 27(4), 567-582.

5. Wilson, T. (2021). "Continuous Improvement Strategies in CNC Machining Quality Control". Total Quality Management & Business Excellence, 32(11-12), 1289-1305.

6. Garcia, M. et al. (2023). "Technology-Driven Quality Assurance in CNC Machining: A Case Study". Journal of Cleaner Production, 350, 131456.

_1756345858191.webp)

_1756346205762.webp)