With its outstanding electrical conductivity, resistance to corrosion, and thermal qualities, copper castings are among the most adaptable and dependable production options available in a variety of sectors. This thorough manual examines the essential elements of choosing a copper alloy, casting procedures, and practical uses that propel contemporary industrial excellence. Knowing the subtleties of copper casting technique helps engineers and procurement specialists make choices that maximize performance, economy, and long-term dependability in their particular applications, ranging from electrical systems to automobile components.

Understanding Copper Alloy Fundamentals

Choosing the right alloy composition is the first step towards effective copper casting. Maximum electrical conductivity is provided by pure copper, but it lacks the mechanical strength needed for demanding applications. Depending on their particular needs, engineers usually choose among bronze alloys, brass compositions, or specialty copper-nickel versions.

Tin is the main alloying ingredient of bronze alloys, which provide exceptional strength and resistance to wear. These materials perform very well in applications involving heavy equipment and maritime conditions when corrosion resistance and durability requirements are met. Grades of phosphor bronze retain their superior spring qualities while offering improved machinability.

Copper and zinc are combined to create brass alloys, which balance strength, corrosion resistance, and affordability. Naval brass performs very well in marine applications because it contains trace quantities of tin. Grades of leaded brass make complicated designs that need precise finishing easier to machine.

In harsh conditions, copper-nickel alloys provide exceptional corrosion resistance. These unique formulations are perfect for aerospace and marine applications because they prevent biofouling and preserve structural integrity in the face of drastic temperature changes.

Core Casting Processes and Techniques

The most popular technique for creating copper components is still sand casting, especially for big or intricate geometries. This procedure maintains cost-effectiveness for both production runs and prototype development while accommodating different batch sizes. Dimensional accuracy and surface finish quality are directly impacted by the composition of the molding sand.

For applications requiring precise copper castings, investment casting, also referred to as lost-wax casting, offers outstanding surface polish and precise tolerances. When creating complex shapes that traditional machining would not be able to achieve, this technique is crucial. Superior detail replication and little material waste are guaranteed by the ceramic shell technique.

Using rotating forces, centrifugal casting produces dense, homogeneous parts with superior metallurgical qualities. This method works especially well for cylindrical components where material density and structural integrity are crucial, such bushings, sleeves, and bearing assemblies.

High-volume manufacturing with reliable dimensional precision is made possible by die casting. Specialized die casting processes allow copper alloys for certain applications that need quick production cycles and little post-processing, even though they are often associated with aluminum and zinc alloys.

Critical Material Properties and Performance Characteristics

The most well-known characteristic of copper is its electrical conductivity; pure copper may reach 100% IACS (International Annealed Copper Standard). Alloying elements improve mechanical qualities but decrease conductivity, necessitating careful balancing according to application requirements.

Effective heat dissipation in heat exchangers and electronic components is made possible by thermal conductivity. Because of its superior thermal characteristics over other industrial materials, copper is essential for temperature control applications in a variety of sectors.

Copper alloys differ greatly in their ability to withstand corrosion. Certain alloy compositions improve resistance to certain conditions, even though copper naturally generates protective patina coatings. Comprehending galvanic compatibility helps multi-metal assemblies avoid expensive breakdowns.

The alloy composition and heat treatment conditions have a significant impact on mechanical strength. Cold working decreases ductility while increasing tensile strength. While optimizing grain structure for particular purposes, annealing treatments restore ductility.

Production schedules and manufacturing costs are influenced by machinability features. Lead or tellurium-containing copper alloys that can be free-machined allow for high-speed machining while still meeting surface polish requirements.

Automotive Industry Applications and Requirements

Copper castings that satisfy strict dimensional standards and provide long-term dependability are required by the automobile industry. Copper's exceptional conductivity capabilities are used in electrical system components such as wire harnesses, alternator housings, and starter motor parts.

The heat management capabilities of brake system components are based on copper-based alloys. Because copper conducts and disperses heat quickly, it helps brake callipers and heat dissipation elements avoid component failure under harsh operating circumstances.

Heat exchangers and radiators made of copper alloy are used in engine cooling systems to maintain ideal operating temperatures. Thermal conductivity and corrosion resistance work together to provide dependable performance in a variety of operating conditions.

Comprehensive material traceability and quality validation are required by PPAP documentation standards. To satisfy automotive quality requirements, copper casting providers must keep thorough records including mechanical characteristics, chemical composition, and dimensional verification.

Industrial Machinery and Heavy Equipment Solutions

Copper castings used in industrial settings must be able to endure harsh working environments without losing their dimensional stability. The resistance of copper alloys to erosion damage and cavitation is advantageous for pump housings, valve bodies, and impeller assembly.

Bronze copper castings are used in gear systems and transmission parts because of their exceptional load-bearing capacity and resistance to wear. Some bronze compositions include self-lubricating qualities that prolong service life and lower maintenance needs.

Procedures for heat treatment maximize the qualities of materials for certain uses. Precipitation hardening procedures improve strength qualities for demanding mechanical applications, whereas stress relief annealing removes residual casting stresses.

Variable demand patterns may be accommodated by flexible batch manufacturing capabilities without sacrificing quality requirements. Lean manufacturing techniques are used in modern foundries to swiftly adjust to shifting volume needs while preserving constant material qualities.

Electrical and Energy Sector Applications

Copper castings are crucial to the electrical conductivity and thermal control of power production equipment. Materials that continue to function under constant electrical loads are needed for switchgear assemblies, transformer parts, and generator windings.

Copper castings are used in energy storage components, solar panel mounting systems, and wind turbine turbines in renewable energy systems. The material's capacity to be recycled supports environmental goals while offering dependable long-term performance.

Sensitive parts are shielded from electromagnetic radiation by motor housings and electrical enclosures. Consistent wall thickness and dimensional correctness are ensured by precision casting procedures, which are essential for appropriate electrical isolation.

Thorough testing and documentation are necessary to comply with industry standards, such as IEC, NEMA, and UL regulations. Electrical characteristics, environmental resistance, and safety performance standards are all covered by material certification.

Aerospace and Defense Requirements

The highest standards of material traceability and quality control are required for aerospace applications. In order to function reliably in harsh environments, copper castings used in aviation electrical systems must adhere to strict certification standards.

In aeronautical applications, material selection is based on weight optimization. Modern copper alloys minimize the total weight of the system while offering strength-to-weight ratios that satisfy performance standards.

Before components are put into operation, non-destructive testing procedures guarantee internal soundness and identify any flaws. Throughout the manufacturing process, casting integrity is verified by penetrant inspection, ultrasonic testing, and X-ray inspection.

In aerospace settings, where components are subjected to drastic temperature fluctuations, temperature cycling resistance is crucial. For harsh service conditions, certain heat treatment cycles maximize grain structure and thermal stability.

Quality Control and Inspection Standards

Coordinate measuring devices and precision gauging systems are used in dimensional accuracy verification to guarantee casting compliance. Statistical process control techniques keep an eye on production consistency and spot any quality problems before they affect delivery dates.

Spectrographic equipment is used in chemical composition analysis of copper castings to confirm that the alloy content falls within predetermined parameters. Across manufacturing batches, representative test results are guaranteed by standardized sampling techniques.

Material strength, hardness, and ductility are validated by mechanical property testing. Quantitative data supporting material certification criteria is provided by tensile testing equipment and hardness testers.

Casting quality is measured by surface finish measurement, which also directs post-processing choices. Surface roughness characteristics that affect the performance of the finished component and future machining processes are measured using profilometry equipment.

Conclusion

In sectors where corrosion resistance, temperature control, and electrical conductivity are critical, copper castings continue to spur innovation. Making well-informed judgments that maximize performance while minimizing expenses requires knowledge of alloy selection, casting procedures, and application-specific requirements. Copper castings are guaranteed to satisfy the exacting specifications of contemporary technical applications thanks to a mix of sophisticated metallurgy, precise production processes, and strict quality control. Implementing copper casting solutions successfully requires working with seasoned vendors that are aware of the unique difficulties facing your sector and have the technical know-how to produce reliable, superior outcomes.

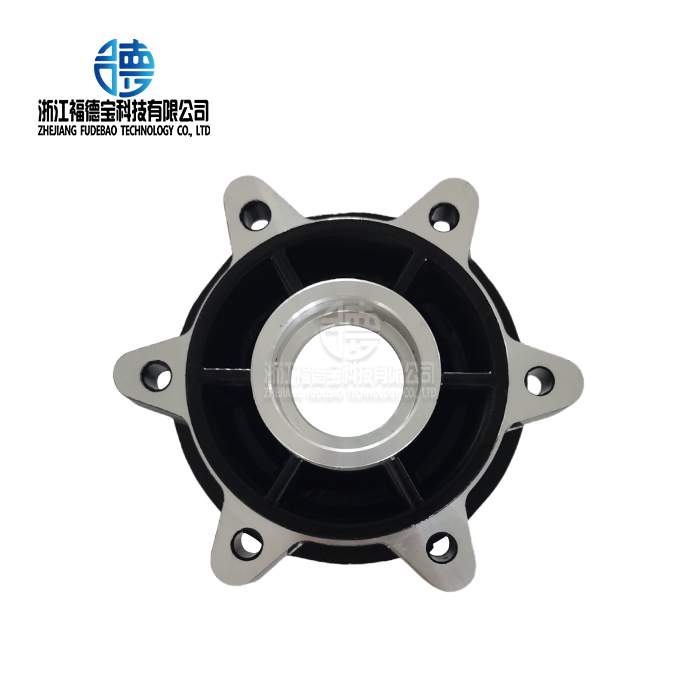

Partner with Fudebao Technology for Premium Copper Castings Manufacturing

Your product development schedule and production success are transformed when you choose the correct copper castings supplier. Zhejiang Fudebao Technology Co., Ltd. provides copper casting solutions that surpass industry standards by fusing cutting-edge production capabilities with decades of metallurgical experience. High-speed machining centers, CNC lathes, and specialist casting equipment spanning the whole process from melting to surface treatment are housed in our extensive facilities.

In order to optimize casting shape, choose suitable alloy compositions, and set production parameters that meet your performance goals, our technical team works closely with your design professionals. We handle batch sizes ranging from prototype quantities to high-volume production runs while maintaining dimensional accuracy up to ±0.05mm.

Complete material traceability, mechanical property certification, and dimensional inspection reports that meet the strictest industry standards are examples of quality documentation. Our ability to satisfy a variety of application needs is shown by our experience working with automobile OEMs, aircraft manufacturers, and makers of industrial equipment.

Are you prepared to see how high-quality copper castings might improve your next project? Our technical experts are prepared to go over your particular needs and provide the best options. Reach out to us at hank.shen@fdbcasting.com to speak with knowledgeable experts who are aware of the intricacies of contemporary copper casting applications.

_1756346205762.webp)

_1756349146076.webp)

_1756349696500.webp)

_1756350092126.webp)