Mastering certain methods and procedures that directly affect product quality, dimensional precision, and manufacturing efficiency is necessary to achieve excellence in aluminum die casting. Contemporary manufacturers that use these tried-and-true processes regularly produce lightweight parts with excellent surface quality and strict casting tolerances for industrial equipment, automotive parts, and aerospace applications.

Why Focus on Advanced Die Casting Techniques

Aluminum die casting has evolved from a simple production technique to a complex technical field due to modern industrial needs. Automobile manufacturers today demand parts that have outstanding mechanical qualities and dimensional tolerances of up to ±0.05mm. These specifications are further pushed by aerospace applications, which need for verified procedures with full manufacturing traceability.

New opportunities for producing intricate geometries with less post-processing have been made possible by the advancement of die casting machine technology. The industry used to struggle with porosity control, but high pressure casting technologies now provide reliable metal flow patterns. Manufacturers may now create lightweight components without sacrificing structural integrity thanks to these advancements.

Casting methods are continuously improved due to energy efficiency concerns. Improved surface finish quality and shorter cycle times are achieved via optimized thermal conductivity control. Engineers can now fine-tune material qualities for particular applications thanks to more accurate heat treatment techniques. Measurable gains in component dependability and manufacturing efficiency are achieved with this all-encompassing approach to process optimization.

Selection Criteria for Optimal Die Casting Practices

Methodical evaluation across many performance aspects is necessary for die casting methodology evaluation. The basis is material selection; aluminum alloys are selected according to certain mechanical characteristics, requirements for thermal conductivity, and requirements for corrosion resistance. Because tool steel molds need large financial outlays, long-term performance depends on careful design and maintenance.

The quality of the finished component is directly impacted by process control factors. To reduce casting flaws, injection speed profiles must strike a compromise between controlled turbulence and quick cavity filling. Dimensional stability and cycle time are also impacted by cooling system design. Consistent material qualities across manufacturing runs are ensured via temperature control throughout the operation.

Protocols for quality assurance provide quantifiable standards for ongoing development. Trends are detected by statistical process control before they affect output. Internal flaws that conventional procedures could overlook are found via advanced examination techniques. The certification standards necessary for automotive PPAP processes and aerospace applications are supported by thorough documentation.

High-Pressure Die Casting for Precision Components

The gold standard for creating intricate aluminum components with remarkable dimensional precision is high-pressure die casting. This process produces dense, highly-strengthened objects with superior surface finish qualities by forcing molten metal into precisely machined cavities at pressures more than 1,500 bar. Even in parts with thin walls, the quick injection procedure ensures full cavity filling while reducing oxidation.

Complex thermal management systems are needed to regulate the temperature during high-pressure activities. Mold temperatures normally fall between 150 and 300°C, and careful regulation keeps the flow properties ideal while avoiding premature solidification. Computational fluid dynamics-designed cooling channels guarantee consistent temperature distribution, lowering thermal stress and enhancing dimensional stability throughout the casting.

Gate design and runner systems significantly impact casting quality. Properly sized gates maintain laminar flow while preventing excessive turbulence. Runner layouts balance filling time with material efficiency. Overflow wells capture initial metal flow, ensuring only clean material enters the final cavity. Together, these design components create parts that satisfy the strictest automotive part requirements.

In order to avoid component damage during extraction, ejection systems need to be carefully engineered. Progressive ejection sequences distribute forces evenly across the casting surface.Surface texturing and draft angles allow for a smooth release while preserving dimensional integrity. Automated ejection systems increase overall production efficiency by decreasing cycle times and improving uniformity.

Low-Pressure Casting for Complex Geometries

When thick-walled components with intricate internal geometries are needed, low-pressure die casting performs very well. By progressively filling mold cavities from bottom to top using regulated pressure differentials, this method removes turbulence-related flaws that are typical in conventional gravity casting. Excellent dimensional precision is maintained while exceptional mechanical qualities are produced by the mild filling operation.

Pressure curve optimization represents a critical success factor in low-pressure operations. Without causing turbulence, regulated cavity filling is made possible by gradual pressure increases. Compared to high-pressure alternatives, typical pressures are much lower, ranging from 0.3 to 1.0 bar.This controlled environment reduces mold wear while producing castings with superior metallurgical properties suitable for industrial equipment applications.

Mold design considerations differ substantially from high-pressure alternatives. Thicker mold sections accommodate the slower filling process while maintaining thermal stability. Cooling channel placement requires careful optimization to ensure directional solidification. In order to handle the softer filling characteristics inherent in low-pressure operations, gating systems usually have bigger cross-sections.

Because of the prolonged periods of contact between molten aluminum and ambient conditions, metal quality becomes crucial in low-pressure applications. Protocols for degassing eliminate dissolved hydrogen that could cause porosity. Oxide inclusions that impair mechanical characteristics are removed using filtration systems. Contamination is avoided throughout the prolonged melting cycles that are characteristic of low-pressure processes thanks to furnace atmosphere management.

Cycle time optimization in low-pressure casting requires balancing filling speed with quality requirements. Automated pressure control systems maintain precise profiles throughout production runs. Consistent thermal conditions are ensured via temperature monitoring. Heat treatment procedures used after casting improve mechanical qualities and reduce internal tensions, resulting in parts fit for demanding aeronautical applications.

Vacuum Die Casting for Premium Applications

By eliminating ambient gasses from mold cavities prior to metal injection, vacuum die casting removes air-related flaws. This cutting-edge method creates castings with remarkable mechanical and density qualities, which make them perfect for high-performance automobile parts and crucial aircraft components. In complicated geometries, the vacuum environment allows for full cavity filling while preventing oxidation.

Vacuum system design requires sophisticated pumping equipment capable of achieving pressures below 100 mbar within seconds. Mold sealing systems prevent air infiltration during the casting process. The time of metal infusion and evacuation is synchronized using vacuum valves. Together, these technologies provide oxygen-free conditions that result in castings with exceptional metallurgical qualities.

Vacuum casting requires very high standards of purity while preparing metal. Dissolved gases that can expand in the vacuum environment are eliminated by degassing procedures. Particles that might jeopardize surface smoothness are removed by filtration systems. Temperature control prevents premature solidification while maintaining optimal flow characteristics throughout the evacuation and injection sequence.

Quality benefits of vacuum casting extend beyond simple defect reduction. Reduced porosity and enhanced grain structure result in a considerable improvement in mechanical characteristics. Surface finish quality often eliminates secondary procedures and approaches that of machined components. Dimensional accuracy improvements result from reduced shrinkage variations and more predictable cooling patterns.

Economic considerations make vacuum die casting attractive for high-value components despite increased process complexity. Reduced scrap rates offset higher equipment costs. Elimination of secondary operations improves overall production efficiency. Enhanced mechanical properties enable weight reduction in finished components, delivering value to automotive and aerospace customers focused on performance optimization.

Semi-Solid Metal Processing Innovation

A cutting-edge method of casting aluminum that combines the benefits of forging and casting is semi-solid metal processing. By processing aluminum alloys in a semi-liquid condition, this method produces distinctive microstructures with remarkable mechanical qualities.The thixotropic behavior of semi-solid metal enables complex shape formation while maintaining superior dimensional accuracy.

Temperature control in semi-solid processing requires precise management of the solidification window. Aluminum alloys typically process within narrow temperature ranges where solid and liquid phases coexist. Electromagnetic stirring systems maintain homogeneous microstructures during the semi-solid state. Specialized heating equipment ensures uniform temperature distribution throughout the material volume.

Reduced segregation, better mechanical qualities, and increased dimensional stability are some of the quality benefits of semi-solid processing. Numerous flaws typical of conventional casting are eliminated by the controlled solidification process.Porosity levels drop significantly due to the absence of turbulent filling. Surface finish quality rivals that of precision machining operations, often eliminating secondary processing requirements.

Applications for semi-solid processing continue expanding as manufacturers recognize the unique benefits. Automotive transmission components benefit from improved wear resistance. Aerospace structural elements achieve weight reduction without compromising strength. Under rigorous working circumstances, industrial equipment components exhibit improved fatigue resistance. These many uses demonstrate how adaptable semi-solid metal processing technology is.

Advanced Squeeze Casting Techniques

By applying constant pressure during solidification, squeeze casting combines the metallurgical advantages of forging with the accuracy of die casting. Castings with remarkable mechanical qualities and dimensional precision are produced using this hybrid method. Dense, high-strength components appropriate for crucial structural applications are produced by removing feeding-related shrinking.

In order to apply pressure in squeeze casting, complex hydraulic systems that can sustain pressures greater than 100 MPa throughout the solidification process are needed. These high pressures are accommodated by die manufacturing while exact dimensional tolerances are maintained.Specialized press equipment coordinates metal pouring with pressure application timing to optimize microstructure development.

Squeeze casting metal preparation places a strong emphasis on temperature control and cleanliness. Oxides and impurities that might affect the final qualities must be kept out of molten aluminum. Degassing processes eliminate dissolved hydrogen that might produce porosity while under pressure. Controlling the temperature during cavity filling guarantees the best fluidity while avoiding early solidification.

Squeeze casting microstructure formation is quite different from traditional techniques. Grain structure is refined and shrinkage porosity is eliminated by prolonged pressure. Oriented microstructures with improved mechanical qualities are produced via directional solidification. In demanding applications, heat treatment techniques optimize these distinct microstructures for particular performance needs.

Squeeze casting has many financial advantages, such as requiring less machining because of its superior surface polish and dimensional precision. Eliminating gating and riser systems enhances material consumption. Improved mechanical qualities allow for component consolidation, which lowers assembly costs. Squeeze casting is appealing for high-performance automotive and aerospace components when quality warrants higher production costs because of these benefits.

Global Market Analysis and Regional Considerations

The worldwide market for aluminum die casting has unique geographical features that are influenced by regional production capacities, legal constraints, and consumer preferences. great-strength aluminum components are in great demand due to North American markets' emphasis on automobile lightweighting programs. European manufacturers prioritize energy-efficient procedures and recyclable materials in order to comply with environmental regulations. Asian markets place a high value on cost reduction and manufacturing efficiency while maintaining quality standards.

Regulatory landscapes vary significantly across global markets, influencing process selection and quality requirements. European RoHS compliance affects surface treatment options. North American automotive standards drive PPAP documentation requirements. Asian quality standards emphasize statistical process control and continuous improvement methodologies. Understanding these regional differences enables manufacturers to optimize processes for specific market requirements.

Supply chain considerations impact global die casting operations through material availability, logistics costs, and quality consistency. Aluminum alloy specifications vary between regions, requiring process adjustments for different material properties. Transportation costs influence component design decisions, with regional production becoming increasingly attractive for high-volume applications. Local supplier capabilities determine feasible complexity levels for different geographic markets.

Cultural preferences influence design requirements and quality expectations across global markets. Asian customers often prioritize surface finish quality and dimensional precision. European buyers emphasize environmental sustainability and energy efficiency. North American markets focus on performance optimization and cost-effectiveness. Successful global manufacturers adapt processes to meet these diverse cultural expectations while maintaining consistent quality standards.

Purchasing Recommendations and Strategic Considerations

Selecting optimal aluminum die casting suppliers requires comprehensive evaluation beyond simple cost comparisons. Technical capabilities assessment should examine equipment sophistication, process control systems, and quality documentation protocols. Site visits reveal actual production capabilities and quality management systems. Reference checks with existing customers provide insights into supplier reliability and problem-solving abilities.

Risk management strategies should address supply chain continuity, quality consistency, and capacity flexibility. Dual sourcing arrangements provide security against disruptions. Quality agreements establish clear performance expectations and measurement criteria. Capacity planning ensures suppliers can accommodate volume fluctuations. These considerations become critical for automotive OEMs and aerospace manufacturers requiring uninterrupted supply chains.

Cost optimization extends beyond unit price to include total cost of ownership considerations. Supplier quality performance affects inspection and sorting costs. Delivery reliability influences inventory carrying costs. Technical support quality impacts engineering time requirements. Comprehensive cost analysis reveals true value propositions that may not be apparent from initial price comparisons alone.

Industry Trends and Future Outlook

The aluminum die casting industry continues evolving through digitalization, sustainability initiatives, and advanced materials development. Industry 4.0 technologies enable real-time process monitoring and predictive maintenance. Artificial intelligence optimizes process parameters for improved quality and efficiency. Additive manufacturing creates new possibilities for complex mold designs. These technological advances promise continued improvement in casting quality and production efficiency while reducing environmental impact through optimized resource utilization.

Conclusion

Mastering aluminum die casting requires comprehensive understanding of materials, processes, and quality systems. Successful manufacturers implement systematic approaches encompassing proper equipment selection, process optimization, and continuous improvement protocols. The techniques discussed provide proven pathways to achieving exceptional component quality while maintaining production efficiency.

Global markets continue demanding higher performance standards, making advanced die casting capabilities essential for competitive success. Companies investing in sophisticated equipment, comprehensive quality systems, and skilled technical teams position themselves to capture emerging opportunities across automotive, aerospace, and industrial sectors. Success requires commitment to excellence at every level of the manufacturing process.

The future of aluminum die casting lies in continued technological advancement and process optimization. Manufacturers embracing these developments while maintaining focus on fundamental quality principles will thrive in an increasingly competitive global marketplace. Strategic partnerships with experienced suppliers become crucial for accessing advanced capabilities while managing complex supply chain requirements.

FAQs

1. What factors most significantly impact aluminum die casting quality?

Die casting quality depends primarily on material preparation, mold design, process control, and cooling management. Metal cleanliness affects final properties, while mold design influences flow patterns and defect formation. Process parameters like injection speed and pressure directly impact dimensional accuracy. Cooling system design affects both cycle time and casting quality, making comprehensive process control essential for consistent results.

2. How do you minimize porosity in aluminum die castings?

Porosity reduction requires multiple coordinated approaches including proper degassing, optimized gating design, controlled injection speeds, and appropriate venting. Vacuum die casting eliminates air-related porosity. Proper metal preparation removes dissolved gases before casting. Gate placement and runner design minimize turbulence during filling. These combined techniques significantly reduce porosity while improving mechanical properties.

3. What are the key differences between high-pressure and low-pressure die casting?

High-pressure die casting uses rapid injection at pressures exceeding 1,500 bar, ideal for thin-walled components with excellent dimensional accuracy. Low-pressure casting uses gentle filling at 0.3-1.0 bar pressure, better suited for thick-walled parts requiring superior mechanical properties. High-pressure processes offer faster cycle times, while low-pressure methods provide better metallurgical properties and reduced mold wear.

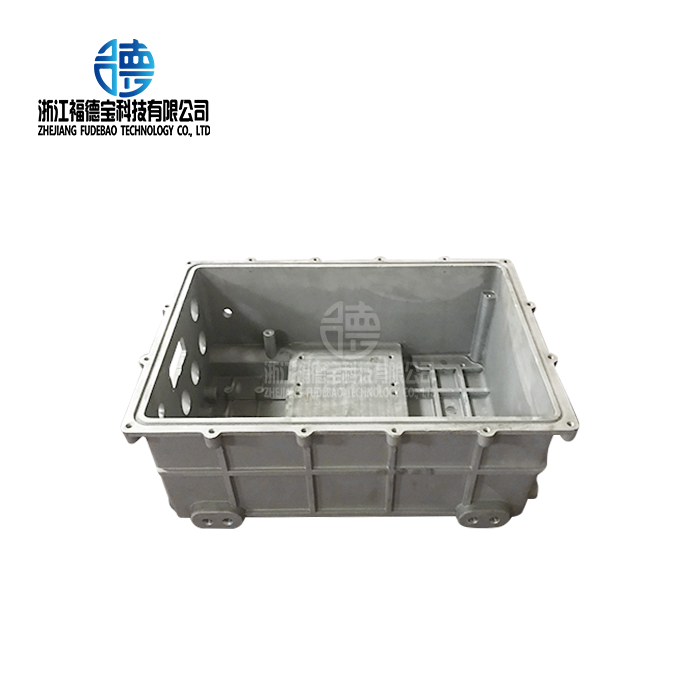

Partner with Fudebao Technology for Superior Aluminum Die Casting Solutions

Achieving excellence in aluminum die casting requires partnering with manufacturers who understand the complexities of modern production requirements. At Fudebao Technology, we combine advanced equipment capabilities with comprehensive process expertise to deliver components meeting the most demanding specifications. Our integrated approach covers the complete production cycle from material preparation through final inspection, ensuring consistent quality across every project.

Our manufacturing capabilities encompass all major die casting methodologies, including high-pressure, low-pressure, and vacuum processes. Advanced equipment includes state-of-the-art die casting machines, precision CNC machining centers, and comprehensive quality control systems. This integrated approach enables us to serve as your trusted aluminum die casting supplier for automotive, aerospace, industrial, and electrical applications requiring exceptional precision and reliability.

Quality certification systems ensure every component meets stringent industry standards. Our PPAP documentation capabilities support automotive OEMs requiring complete traceability. Aerospace applications benefit from our certified quality management systems. Statistical process control provides objective evidence of consistent performance across production runs. These quality systems demonstrate our commitment to delivering reliable components that exceed customer expectations.

Ready to optimize your component sourcing strategy with proven aluminum die casting expertise? Our engineering team stands ready to discuss your specific requirements and develop customized solutions that enhance your product performance while reducing total costs. Contact us at hank.shen@fdbcasting.com to explore how our comprehensive capabilities can support your next project with precision, reliability, and exceptional service.

_1756346144394.webp)

_1756348489473.webp)

_1756361494985.webp)