Understanding the Basics of CNC Machining

The Fundamentals of CNC Technology

Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology has transformed the landscape of manufacturing, allowing for precise, repeatable, and complex shaping of materials such as metals, plastics, wood, and composites.

At its core, CNC machining relies on a digital blueprint, typically created using Computer-Aided Design (CAD) software. This design is then translated into a series of commands that control the machining tools. The beauty of CNC lies in its ability to execute intricate designs with remarkable accuracy, often achieving tolerances as tight as ±0.05mm.

The Role of Axes in CNC Machining

In CNC machining, axes refer to the directions in which the cutting tool can move. These movements are crucial in determining the complexity and capabilities of the machining process. The number of axes a CNC machine has directly impacts its versatility and the types of parts it can produce.

Linear axes (X, Y, and Z) allow for straight-line motion, while rotary axes (A, B, and C) enable rotational movement. The combination of these axes determines whether a machine is classified as 3-axis, 4-axis, or 5-axis, each offering different levels of complexity and capability in part production.

The Evolution from Manual to CNC Machining

The journey from manual machining to CNC technology represents a significant leap in manufacturing capabilities. Traditional manual machining relied heavily on the skill and experience of individual machinists. While this approach allowed for custom work, it was time-consuming and prone to human error.

CNC machining introduced a level of precision and repeatability previously unattainable. It democratized complex manufacturing processes, allowing for consistent production of intricate parts across various industries. This evolution has been particularly impactful in fields requiring high precision, such as aerospace, automotive, and medical device manufacturing.

Diving Deep into 3-Axis CNC Machining

The Mechanics of 3-Axis Machining

3-axis CNC machining is the foundation of modern CNC technology. In this setup, the cutting tool moves along three linear axes: X (left to right), Y (front to back), and Z (up and down). This configuration allows for three-dimensional movement, enabling the creation of a wide range of parts and components.

The simplicity of 3-axis machining lies in its straightforward approach. The workpiece remains stationary while the cutting tool moves around it, removing material to create the desired shape. This method is particularly effective for parts that don't require undercutting or complex angular approaches.

Applications and Advantages of 3-Axis CNC

3-axis CNC machines excel in producing parts with relatively simple geometries. They are ideal for creating flat surfaces, straight holes, and basic 3D contours. Industries such as woodworking, signage, and prototype development frequently utilize 3-axis machining for its efficiency and cost-effectiveness.

One of the key advantages of 3-axis machining is its accessibility. These machines are generally less expensive than their multi-axis counterparts, making them a popular choice for small to medium-sized manufacturing operations. They also require less complex programming, reducing the learning curve for operators and programmers.

Limitations of 3-Axis Machining

While 3-axis CNC machines are versatile, they do have limitations. Complex parts with undercuts or features requiring tool access from multiple angles often necessitate multiple setups or specialized fixtures. This can increase production time and potentially impact precision.

Additionally, 3-axis machines may struggle with highly intricate designs or parts requiring simultaneous machining from various angles. In such cases, the limitations of 3-axis movement can result in longer machining times or the need for additional finishing processes.

Exploring the Capabilities of 5-Axis CNC Machining

The Advanced Mechanics of 5-Axis CNC

5-axis CNC machining represents a significant advancement in manufacturing technology. In addition to the three linear axes (X, Y, and Z) found in 3-axis machines, 5-axis CNC incorporates two additional rotary axes. These are typically labeled as A (rotation around the X-axis), B (rotation around the Y-axis), or C (rotation around the Z-axis).

This configuration allows the cutting tool or the workpiece to be oriented in virtually any position relative to each other. The result is a machine capable of approaching a part from almost any angle, enabling the creation of complex geometries in a single setup.

Advantages and Applications of 5-Axis Machining

The capabilities of 5-axis machining open up a world of possibilities in part design and production. Complex contours, deep cavities, and intricate undercuts become achievable without the need for multiple setups or specialized fixtures. This not only enhances precision but also significantly reduces production time for complex parts.

Industries such as aerospace, automotive, and medical device manufacturing benefit greatly from 5-axis technology. It allows for the production of turbine blades, engine components, orthopedic implants, and other parts with complex geometries that would be challenging or impossible with 3-axis machining.

Challenges and Considerations in 5-Axis Machining

While 5-axis machining offers numerous advantages, it also comes with its own set of challenges. The complexity of 5-axis systems requires more sophisticated programming and a higher level of operator expertise. The initial investment in 5-axis machinery is also significantly higher than that of 3-axis equipment.

Additionally, the increased complexity can lead to potential collisions between the tool and the workpiece if not properly programmed. This necessitates advanced simulation software and careful planning to ensure safe and efficient operation.

Conclusion

The choice between 3-axis and 5-axis CNC machining depends on the specific requirements of each project. 3-axis machining remains a reliable and cost-effective solution for simpler parts and prototypes, offering accessibility and ease of use. On the other hand, 5-axis machining opens up new possibilities in complex part production, enhancing efficiency and precision for intricate designs. As manufacturing technology continues to evolve, both 3-axis and 5-axis machining will play crucial roles in meeting diverse production needs across various industries.

FAQs

What is the main difference between 3-axis and 5-axis CNC machining?

The main difference lies in the number of directions the cutting tool can move. 3-axis machines move along three linear axes, while 5-axis machines add two rotary axes for more complex movements.

Which industries benefit most from 5-axis CNC machining?

Industries that require complex parts, such as aerospace, automotive, and medical device manufacturing, benefit greatly from 5-axis CNC machining.

Is 5-axis machining always better than 3-axis?

Not necessarily. While 5-axis machining offers more capabilities, 3-axis machining is often more cost-effective and simpler for parts that don't require complex geometries.

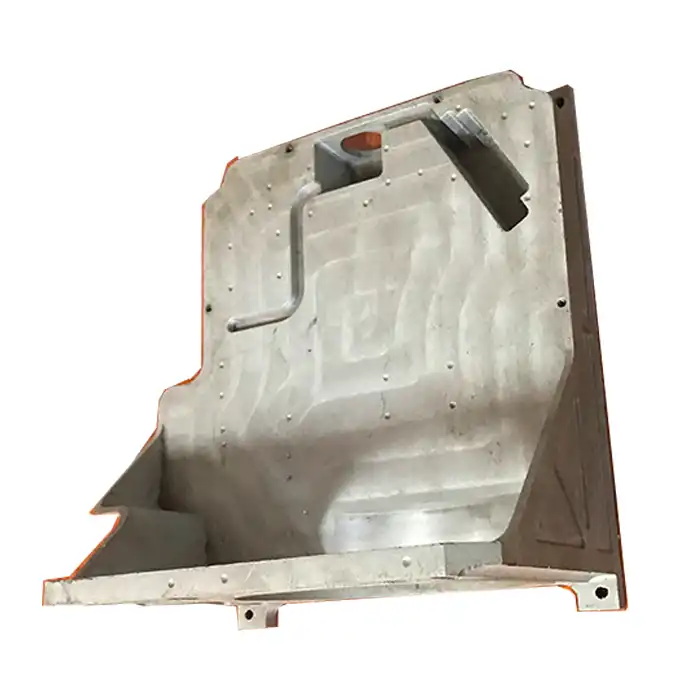

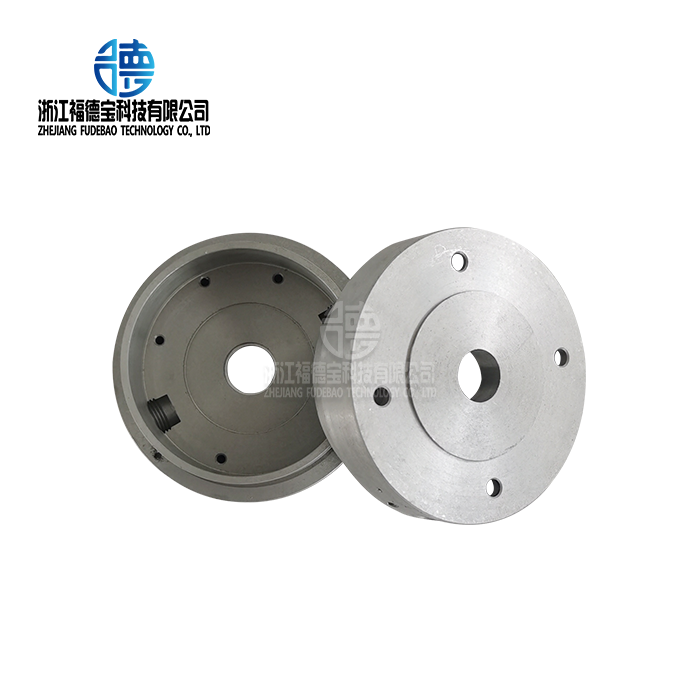

Expert CNC Machining Solutions | Fudebao Technology

At Fudebao Technology, we specialize in both 3-axis and 5-axis CNC machining, offering tailored solutions for your manufacturing needs. As a leading supplier and manufacturer in the field, we provide precision machining services for a wide range of industries. Our state-of-the-art facility and expert team ensure the highest quality results for every project. For more information or to discuss your specific requirements, please contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). "Advanced CNC Machining Techniques: A Comprehensive Guide"

Johnson, R. (2021). "The Evolution of CNC Technology in Manufacturing"

Brown, A. (2023). "Comparative Analysis of 3-Axis and 5-Axis CNC Machining"

Lee, S. (2022). "Applications of 5-Axis CNC Machining in Aerospace Industry"

Wilson, M. (2023). "Cost-Benefit Analysis of 3-Axis vs 5-Axis CNC Machining"

Taylor, P. (2021). "Precision Engineering: The Role of CNC Machining in Modern Manufacturing"

_1756348489473.webp)

_1756352561845.webp)