ASTM B584 Copper Alloy Castings Explained

2026-02-02

ASTM B584 copper alloy castings are an important standard that says what the chemical make-up, mechanical features, and quality standards are for copper-based castings that are used in many fields. These unique copper castings are very resistant to corrosion, carry heat and electricity very well, and are easy to machine. This makes them essential for a wide range of uses, from marine hardware to electrical parts. The standard covers different metal grades, such as C93200 (bearing bronze), C95400 (aluminum bronze), and C86300 (manganese bronze). Each grade is designed to work well in tough industrial settings.

Understanding ASTM B584 Copper Alloy Castings

ASTM B584 sets out detailed rules for castings made of copper alloys that are used in important ways in aerospace, automobile, industrial machinery, and electrical systems. This standard spells out exact chemical makeups and mechanical features that make sure products always work well and reliably in tough working conditions.

Chemical Composition and Alloy Variants

The ASTM B584 standard covers a number of different grades of copper alloys, each of which is made for a particular use. C93200 bearing bronze is made up of about 83% copper, 7% tin, 7% lead, and 3% zinc. It has great bearing qualities and doesn't wear down easily. C95400 aluminum bronze is made of 85% copper and 11% aluminum, which makes it stronger and less likely to rust in marine settings. Copper, manganese, and zinc are mixed together in C86300 manganese bronze to make it very strong and flexible.

These alloy mixtures are put through a lot of tests to make sure they meet ASTM standards. Chemical research makes sure that the ratios of elements are correct, and mechanical testing checks the tensile strength, yield strength, and elongation properties. The controlled composition makes sure that the performance characteristics that are needed for engineering uses can be predicted.

Superior Material Properties

Metal casts made according to ASTM B584 have unique qualities that set them apart from other materials. The heat transfer rate is between 40 and 120 W/mK, based on the alloy. This makes these materials perfect for use in heat exchangers and electrical applications. The electrical conductivity is usually between 15 and 45% of pure copper's, and the mechanical strength is still very high.

Another important benefit is that it doesn't rust, which is especially useful in marine and chemical processing settings. Aluminum bronze alloys are very resistant to corrosion in seawater, while tin bronzes are very good in normal air circumstances. This means that the product will last longer and require less upkeep, which is good for end users.

Industrial Applications and Performance Benefits

Bronze casts and copper-based parts are used a lot in many different fields. These materials are used in engine parts, transmission parts, and electrical connections for cars, where managing heat and conducting electricity are very important. Copper metal castings are used in industrial machinery to make parts like pump housings, valve bodies, and bearings that need to be strong and not rust.

These materials are used to make motor housings, transformer parts, and tools for distributing power in the electrical and energy sectors. Copper alloy casts are the only way to go in these situations because they are both electrically and mechanically strong. In aerospace applications, aluminum bronzes are used because they are lightweight and can keep their shape in harsh circumstances.

The Copper Casting Process According to ASTM B584

Copper alloy casts that meet ASTM B584 standards must be made using complex metallurgical methods and strict quality controls. There are many steps in the production process, and each one is important for getting the right properties and dimensions for commercial uses.

Melting and Alloying Operations

The casting process starts with exact melting that is done in electric induction furnaces that can reach temperatures of more than 1200°C. Before they are put into the oven, the raw materials are carefully chosen and analyzed. Copper cathodes, tin, aluminum, and other alloying elements are mixed in a way that meets ASTM standards.

Controlling the temperature during melting makes sure that the alloying elements dissolve properly and stops oxidation, which could damage the material's qualities. Degassing or protective atmospheres get rid of dissolved gases that could make finished casts porous. Before filling starts, the chemical makeup of the molten metal is checked.

Casting Methods and Quality Assurance

Sand casting is still the most common way to make complex copper castings because it allows for more design freedom and lower costs for smaller batches. Investment casting gives precision parts with a smooth surface and accurate dimensions that don't need much finishing. For important uses, low-pressure casting methods improve density and mechanical properties.

Real-time monitoring of casting parameters like pouring temperature, cooling rates, and mold conditions is part of quality assurance routines. Radiographic inspection and ultrasound testing are two examples of non-destructive testing methods that can find problems inside a product that could affect its performance. As required by ASTM, mechanical testing confirms the tensile qualities, hardness, and elongation.

Comparative Analysis with Alternative Materials

When looking at different types of materials, copper metal castings are clearly better than steel, aluminum, or brass. Copper metals are better at resisting corrosion and conducting heat, but steel castings are stronger. Even though aluminum is lighter than bronze, it can't compare to its ability to conduct electricity or prevent wear.

Brass castings are similar to copper metals in some ways, but they are usually not as strong or resistant to corrosion. The higher copper level in ASTM B584 alloys makes them work better in tough situations. When figuring out costs, you have to weigh the costs of materials against their expected performance benefits and service life.

Procurement Insights for ASTM B584 Copper Alloy Castings

To successfully buy ASTM B584 copper alloy castings, you need to know about global supply lines, the requirements for quality certification, and ways to cut costs. Today's buying teams have to deal with complicated networks of suppliers while keeping quality standards high and making sure deliveries happen on time.

Supplier Evaluation and Certification

To find qualified foundries, you have to look at their technical skills, quality systems, and certifications in the business. Leading suppliers have quality control systems that are in line with ISO 9001. They also often have other certifications, like AS9100 for aerospace applications or TS 16949 for automotive parts. Metallurgical skills, such as spectrographic analysis tools and mechanical testing facilities, make sure that ASTM standards are always met.

Lead times and logistics prices are affected by where things are located. North American foundries are closer for customers in the United States, while Asian suppliers may offer lower prices for big orders. Many facilities in Europe focus on making high-precision castings and other advanced processes. Audits of suppliers check their abilities and set standard agreements that protect buyers' interests.

Cost Factors and Price Optimization

Copper metal casting prices are affected by many factors, with the cost of raw materials being the most important. Copper prices change depending on what's going on in the world market, so long-term deals help with budgeting. The price of an alloy depends on how complicated it is; unique grades cost more than standard compositions.

Foundries get economies of scale when they make more of something, so the number of orders has a big effect on the unit costs. Tooling costs for sand casting are still pretty low, but designs and ceramic shells cost more up front for investment casting. Adding value through secondary processes like machining, heat treatment, and surface finishing costs more than they add value.

Lead Time Management and Logistics

Standard copper alloy castings take 4 to 8 weeks to make, while unique designs can take 12 to 16 weeks, which includes the time it takes to make the pattern and get approval. Rush orders can speed up shipping, but they usually cost more. Planning purchases around known needs helps keep costs down and makes sure things are available when they're needed.

Shipping methods, customs paperwork, and possible delays at ports of entry are all things that need to be thought about when doing international operations. Air freight is the fastest way to send packages, but it costs a lot more to move. Ocean freight is cheaper for big shipments, but it takes longer to get the goods to their destination. The right packing keeps castings safe while they're being shipped and stops damage that could cause project delays.

Key Considerations When Choosing ASTM B584 Copper Alloy Castings

To choose the right copper castings, you have to think about a lot of things, like technical needs, environmental conditions, cost concerns, and following the rules. To choose the best materials for different uses, engineering teams have to look at these factors.

Mechanical Property Requirements

Different ASTM B584 metals have different amounts of strength, ductility, and hardness. C95400 aluminum bronze has tensile strengths above 90 ksi and is very resistant to corrosion, so it can be used in naval settings. The wear resistance and conformability of C93200 bearing bronze are better for bearing applications, but the total strength is lower.

The type of alloy chosen is based on its load needs, resistance to fatigue, and impact toughness. For dynamic uses, alloys with higher elongation values are better, while for static structural parts, final tensile strength may be more important. When choosing a material, temperature is important because some alloys keep their features better at higher temperatures.

Environmental and Regulatory Factors

The operating climate has a big effect on how well and how long an alloy lasts. For marine uses, alloys must be resistant to corrosion in salt water, and for chemical processes, they must be compatible with certain chemicals and pH levels. Atmospheric corrosion is different in different places and at different amounts of pollution, which affects the choice of materials for outdoor use.

Different industries and uses have different regulatory compliance standards. The FDA has rules about what materials can be used and how the surfaces of food processing tools should be finished. Copper alloys need to be NSF-certified before they can be used in drinking water uses. Traceability documentation and material certifications that show compliance with industry norms are needed for aerospace components.

Manufacturing and Processing Considerations

Component complexity affects the choice of casting method and, in turn, the choice of material. For complicated shapes, investment casting may be needed with alloys that flow well and reduce shrinking flaws. Sand casting works best for big, simple forms made of cheap alloys.

The type of machining needed affects the choice of alloy, since some compositions are easier to make than others. Lead-bearing metals are very easy to work with, but they may not be suitable for all uses. Free-machining grades lower the cost of additional operations, but they might give up some mechanical properties. Both the casting method and the alloy used are affected by the surface finish standards and the size tolerances.

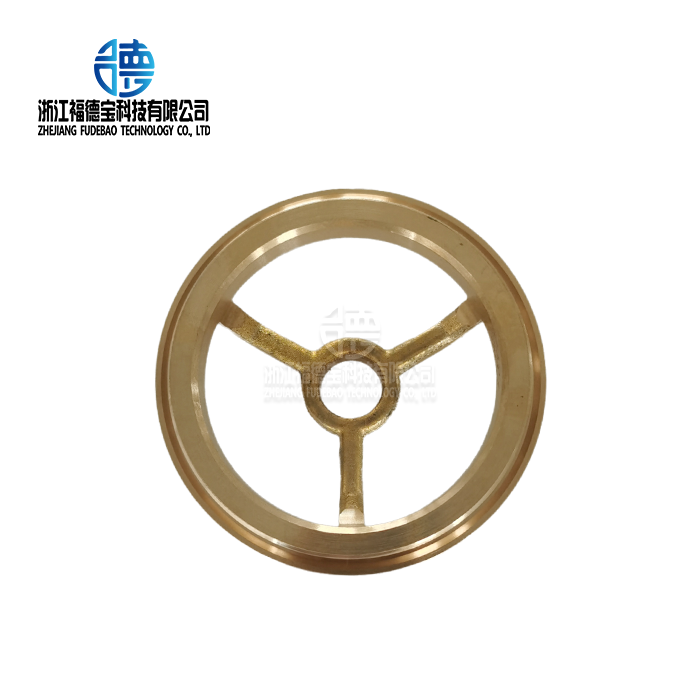

Fudebao Technology: Advanced Copper Alloy Casting Solutions

Zhejiang Fudebao Technology Co., Ltd. is a top company that makes precise copper alloy casts that meet the strict ASTM B584 standards. Our full range of manufacturing services includes melting and casting, as well as precise cutting and surface treatment, so we can give you finished parts that are ready to use right away.

Manufacturing Excellence and Quality Systems

Our modern building has high-tech machines like high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment. By using this unified method, we can keep the accuracy of the dimensions within ±0.05mm, which meets the exact needs of precision parts for cars, medical equipment housings, and aircraft parts.

Through strict process controls and testing methods, quality management systems make sure that ASTM B584 standards are always followed. To check the properties of materials, our metallurgical lab does chemical analysis, mechanical testing, and microstructural study. Traceability systems keep track of materials from the time they are received as raw materials until they are inspected for quality control. This gives important applications full documentation.

Comprehensive Product Portfolio and Services

Fudebao Technology makes a wide range of copper castings, such as bearing bronzes, aluminum bronzes, and manganese bronzes, which are used in many different industries. Our range of products includes electrical housings and engine parts for original equipment manufacturers (OEMs) in the car industry, pump housings and valve bodies for OEMs in the industrial equipment sector, and motor parts and electrical connectors for clients in the energy sector.

Value-added services make our core casting skills better and give customers full solutions. Advanced CNC machines are used in precision cutting to get very tight tolerances and high-quality surface finishes. Services that use heat to improve mechanical qualities make them better for certain uses. Surface treatments like plating, anodizing, and protective coats make things look better and make them less likely to rust.

Global Partnership and Technical Support

We can serve customers all over the world thanks to our international presence. We also offer quick technical help and customer service. We can meet strict quality and delivery standards because we have direct supply relationships with well-known brands like American HAAS automation machine tools and ESS energy storage systems.

Technical advice services help customers choose the best materials and designs for ease of production. During product creation, our engineering team works with clients to find solutions that meet performance needs and don't cost too much. With rapid prototyping, you can quickly test out new ideas before committing to making the actual tools.

Conclusion

ASTM B584 copper alloy castings are important for businesses that need materials with good resistance to corrosion, thermal conductivity, and mechanical properties. When engineering and purchasing teams know about the different alloy grades, how they are made, and what to think about when buying them, they can make choices that are better for both performance and cost. These materials are essential for important uses in the aerospace, automotive, industrial, and electrical fields because they have proven metallurgical properties, quality standards, and dependable supply chains. Working with seasoned makers like Fudebao Technology guarantees access to high-quality castings backed by a wealth of technical know-how and the ability to ship goods all over the world.

FAQ

What makes ASTM B584 copper alloys different from other standards for metal casting?

According to ASTM B584, there are specific chemical makeups and mechanical qualities for copper-based alloys that make them ideal for casting. B584 alloys are different from wrought copper standards because they are made to be cast easily while still having great corrosion resistance, heat conductivity, and mechanical strength. The standard covers a number of different alloy grades, such as bearing bronzes, aluminum bronzes, and manganese bronzes. Each grade is made for a different set of uses and situations.

How long does it usually take to get a special order of ASTM B584 copper alloy?

Standard copper alloy casts take 4–8 weeks to make and deliver, while custom designs can take 12–16 weeks, which includes the time it takes to make the pattern and get approval. Complex geometries or specialty metals may need more time to prepare the tools and improve the process. Rush orders can speed up delivery times, but extra fees may apply based on the foundry's capacity and the supply of materials.

In terms of cost and efficiency, how do copper castings and machined copper parts compare?

When it comes to complicated shapes and medium to high-volume needs, copper castings are a very cost-effective option. Casting cuts down on the waste of material that comes with machining and makes it possible to make complex forms that would be hard or impossible to machine. For precise uses, however, machined parts may offer better dimensional accuracy and surface finish. Depending on the difficulty of the part and the amount of work that needs to be done, the break-even point is usually between 50 and 100 pieces.

Partner with Fudebao Technology for Premium Copper Castings

Achieve your project goals with Fudebao Technology's expertise in ASTM B584 copper alloy castings. Our comprehensive manufacturing capabilities and precision machining services deliver components that meet your exact specifications while maintaining competitive pricing. Connect with our engineering team at hank.shen@fdbcasting.com to discuss your copper castings requirements and receive personalized technical consultation. As a trusted copper castings supplier, we provide complete solutions from prototype development through production delivery, ensuring your success in today's competitive marketplace.

References

ASTM International. "ASTM B584-18: Standard Specification for Copper Alloy Sand Castings for General Applications." ASTM International Standards Worldwide, 2018.

Copper Development Association. "Copper Alloy Casting Design Guidelines and Properties Handbook." Copper Development Association Technical Publication, 2019.

American Foundry Society. "Copper and Copper Alloy Casting Technology and Quality Control Methods." AFS Technical Report Series, 2020.

Materials Properties Handbook. "Mechanical and Physical Properties of ASTM B584 Copper Alloys." ASM International Materials Reference, 2021.

International Copper Association. "Industrial Applications and Performance Characteristics of Copper Alloy Castings." ICA Technical Bulletin, 2019.

Foundry Management & Technology. "Quality Assurance and Testing Protocols for Copper Alloy Castings." FM&T Industry Standards Review, 2020.

_1756346668222.webp)

_1756352625880.webp)

_1756352822273.webp)