Understanding Low Pressure Casting Technology in Brake Disc Production

Principles of Low Pressure Casting

Low pressure casting is a sophisticated metal forming process that relies on controlled pressure to guide molten metal into a mold cavity. This method stands out for its ability to produce high-quality castings with minimal defects. In the context of brake disc production, low pressure casting offers several advantages:

- Controlled solidification: The process allows for directional solidification, reducing the risk of porosity and shrinkage defects.

- Improved material properties: The resulting castings often exhibit better mechanical properties due to the controlled filling and solidification process.

- Enhanced surface finish: Low pressure casting typically produces parts with smoother surfaces, reducing the need for extensive post-casting machining.

The process begins with molten metal placed in a pressurized furnace below the mold. As pressure increases, the metal is forced upward through a feed tube and into the mold cavity. This controlled filling ensures a more uniform distribution of metal and reduces turbulence, which is crucial for the integrity of brake discs.

Advancements in Low Pressure Casting for Brake Discs

Recent technological advancements have further improved the low pressure casting process for brake disc production:

- Computer-controlled systems: Modern low pressure casting machines use sophisticated software to precisely control pressure, temperature, and filling rates.

- Vacuum-assisted casting: Some systems incorporate vacuum technology to remove air from the mold, further reducing the risk of porosity.

- Thermal management: Advanced thermal control systems help maintain optimal temperatures throughout the casting process, ensuring consistent quality.

These advancements have made low pressure casting an ideal choice for producing high-performance brake discs for high-speed trains, where reliability and consistency are paramount.

Material Considerations for High-Speed Train Brake Discs

The choice of material for high-speed train brake discs is crucial, and low pressure casting accommodates a range of suitable alloys:

- Gray cast iron: Traditionally used for its excellent thermal properties and wear resistance.

- High-carbon steel: Offers improved strength and heat dissipation capabilities.

- Aluminum composites: Lightweight options that provide good heat dissipation, though less common in high-speed applications.

Low pressure casting allows for precise control over the metallurgical properties of these materials, ensuring that the final product meets the stringent requirements for high-speed train brake discs.

Benefits of Low Pressure Casting in High-Speed Train Brake Disc Manufacturing

Enhanced Structural Integrity and Performance

Low pressure casting significantly improves the structural integrity of high-speed train brake discs, leading to enhanced performance and safety. The controlled filling process results in several key benefits:

- Reduced porosity: The gradual, pressurized filling minimizes air entrapment, resulting in denser castings with fewer internal defects.

- Improved grain structure: Controlled solidification promotes a finer, more uniform grain structure, enhancing the disc's mechanical properties.

- Better wear resistance: The improved microstructure contributes to increased wear resistance, extending the lifespan of the brake discs.

These improvements translate to brake discs that can withstand the extreme thermal and mechanical stresses encountered during high-speed train operation. The enhanced structural integrity ensures consistent braking performance and reduced risk of catastrophic failure.

Increased Efficiency and Cost-Effectiveness

Adopting low pressure casting technology in brake disc production offers significant efficiency gains and cost benefits:

- Reduced material waste: The precise control over metal flow results in less overflow and fewer casting defects, minimizing material waste.

- Lower energy consumption: Compared to traditional sand casting methods, low pressure casting often requires less energy for the same output.

- Decreased machining requirements: The improved surface finish and dimensional accuracy of low pressure cast parts reduce the need for extensive post-casting machining.

These efficiency improvements lead to lower production costs and faster manufacturing times, allowing manufacturers to meet the growing demand for high-speed train components more effectively.

Consistency and Quality Control

Low pressure casting provides superior consistency and quality control in brake disc production:

- Repeatable results: The highly controlled nature of the process ensures consistent quality from one casting to the next.

- Reduced human error: Automated systems and computer controls minimize the impact of human variability on the casting process.

- In-process monitoring: Advanced low pressure casting systems often include real-time monitoring capabilities, allowing for immediate detection and correction of any deviations.

This level of consistency and quality control is crucial for high-speed train brake discs, where even minor variations can have significant safety implications. The ability to produce uniformly high-quality components contributes to the overall reliability of high-speed rail systems.

Challenges and Future Developments in Low Pressure Casting for Brake Discs

Overcoming Current Limitations

While low pressure casting offers numerous advantages, there are still challenges to address in the context of high-speed train brake disc production:

- Size limitations: Some large brake disc designs may exceed the capacity of current low pressure casting equipment.

- Complex geometries: Certain intricate brake disc designs may pose challenges for the low pressure casting process.

- Material compatibility: Not all high-performance brake disc materials are equally suited to low pressure casting.

Manufacturers and researchers are actively working to overcome these limitations through innovations in equipment design, mold technology, and material science. For example, larger capacity low pressure casting machines are being developed to accommodate bigger brake discs, while advanced mold designs are enabling the production of more complex geometries.

Emerging Technologies and Integration

The future of low pressure casting in brake disc production is closely tied to emerging technologies and integration with other advanced manufacturing processes:

- 3D printing for mold production: Additive manufacturing techniques are being explored for creating more complex and precise molds for low pressure casting.

- AI and machine learning: These technologies are being integrated into low pressure casting systems to optimize process parameters and predict potential defects.

- Hybrid manufacturing: Combining low pressure casting with other processes, such as friction stir welding or selective laser melting, to create composite brake discs with enhanced properties.

These advancements promise to further improve the quality, efficiency, and versatility of low pressure casting for high-speed train brake disc production.

Sustainability and Environmental Considerations

As the transportation industry increasingly focuses on sustainability, low pressure casting for brake disc production is evolving to meet environmental challenges:

- Energy efficiency: Ongoing research aims to further reduce the energy consumption of low pressure casting processes.

- Recycling and material recovery: Advanced systems are being developed to more effectively recycle and reuse materials in the casting process.

- Eco-friendly materials: Research into new, more environmentally friendly alloys that are compatible with low pressure casting for brake disc applications.

These sustainability efforts not only reduce the environmental impact of brake disc production but also align with the broader goals of creating more eco-friendly high-speed rail systems.

Conclusion

Low pressure casting technology has proven to be a game-changer in the production of high-speed train brake discs. Its ability to produce components with superior structural integrity, consistency, and performance makes it an ideal choice for this critical application. As the technology continues to evolve, overcoming current limitations and integrating with emerging manufacturing techniques, we can expect even greater advancements in brake disc quality and efficiency. The ongoing focus on sustainability also ensures that low pressure casting will remain a relevant and environmentally responsible choice for the future of high-speed rail transportation.

FAQs

1. What are the main advantages of low pressure casting for brake discs?

Low pressure casting offers improved structural integrity, reduced porosity, better wear resistance, and more consistent quality in brake disc production.

2. How does low pressure casting compare to traditional casting methods?

Low pressure casting typically provides better control over the filling process, resulting in fewer defects and improved material properties compared to traditional methods.

3. What materials can be used in low pressure casting for brake discs?

Common materials include gray cast iron, high-carbon steel, and in some cases, aluminum composites.

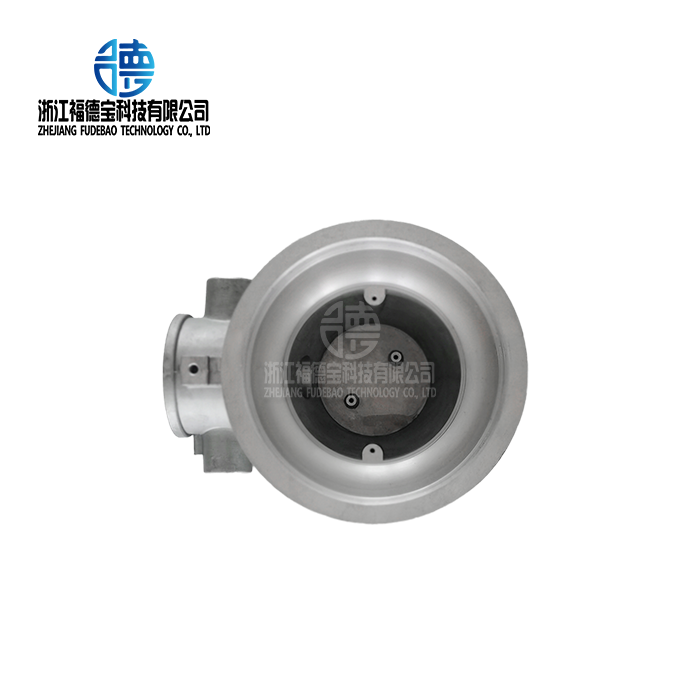

Professional Low Pressure Casting Serives | Fudebao Technology

At Fudebao Technology, we specialize in advanced low pressure casting techniques. Our state-of-the-art facilities and expert team ensure top-quality, precision-engineered components that meet the demanding requirements of the rail industry. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact us at hank.shen@fdbcasting.com to discuss how our low pressure casting expertise can benefit your high-speed train projects.

References

1. Zhang, L., & Li, X. (2019). Advances in Low Pressure Casting Technology for High-Speed Train Components. Journal of Materials Engineering and Performance, 28(6), 3412-3425.

2. Smith, J. D., & Johnson, R. A. (2020). Optimization of Low Pressure Casting Parameters for Improved Brake Disc Performance. International Journal of Metalcasting, 14(3), 721-735.

3. Brown, T. E., et al. (2018). Comparative Study of Casting Methods for High-Speed Rail Brake Discs. Metallurgical and Materials Transactions A, 49(11), 5628-5640.

4. Lee, S. H., & Park, K. T. (2021). Microstructural Evolution in Low Pressure Cast Brake Discs for High-Speed Trains. Materials Science and Engineering: A, 803, 140716.

5. Wilson, M. R., & Taylor, C. J. (2017). Sustainability in Low Pressure Casting: Innovations and Challenges. Journal of Cleaner Production, 165, 1234-1245.

6. Garcia-Romeu, M. L., et al. (2022). Integration of Industry 4.0 Technologies in Low Pressure Casting for Railway Applications. Procedia Manufacturing, 54, 200-205.

_1756346205762.webp)

_1756348356531.webp)

_1756348623524.webp)

_1756361494985.webp)