Understanding Hot Tearing in Copper Castings

What is Hot Tearing

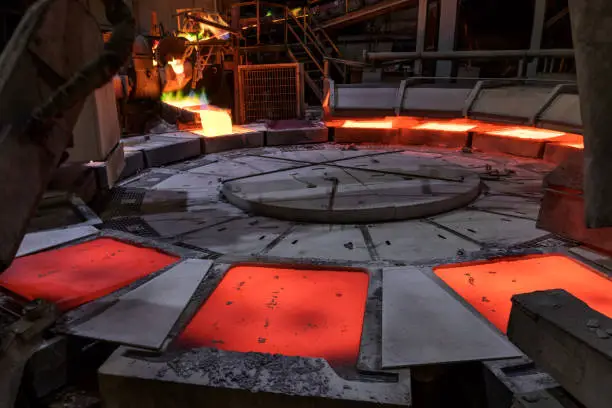

Hot tearing, also known as hot cracking, is a common defect in copper castings that occurs during the solidification process. It happens when the partially solidified metal is subjected to thermal stresses and lacks the necessary strength to withstand these forces. The result is the formation of cracks or tears in the casting, which can compromise its structural integrity and functionality.

Factors Contributing to Hot Tearing

Several factors contribute to the occurrence of hot tearing in copper castings:

- Alloy composition

- Solidification range

- Cooling rate

- Mold design

- Pouring temperature

- Casting geometry

Understanding these factors is crucial for developing effective strategies to prevent hot tearing and improve the overall quality of copper castings.

Impact on Casting Quality

Hot tearing can have severe consequences on the quality and performance of copper castings. Some of the negative impacts include:

- Reduced mechanical strength

- Decreased corrosion resistance

- Compromised dimensional accuracy

- Increased scrap rates

- Higher production costs

By addressing hot tearing issues, manufacturers can significantly improve the quality and reliability of their copper castings.

Analyzing the Mechanisms of Hot Tearing

Thermal Contraction and Stress Development

During solidification, copper alloys undergo thermal contraction, which can lead to the development of internal stresses. These stresses, if not properly managed, can result in hot tearing. The key factors influencing thermal contraction include:

- Solidification temperature range

- Cooling rate

- Thermal gradients within the casting

Understanding these mechanisms helps in developing targeted strategies to minimize hot tearing in copper castings.

Dendrite Coherency and Feeding

The formation of dendrites during solidification in copper castings plays a crucial role in hot tearing susceptibility. As dendrites grow and interlock, they form a coherent network that can restrict the flow of liquid metal to feed shrinkage. This phenomenon, known as dendrite cohenrency, can lead to the formation of hot tears if not properly addressed in copper castings.

Factors affecting dendrite coherency and feeding in copper castings include:

- Alloy composition

- Cooling rate

- Grain structure

- Mold design

Grain Boundary Sliding and Liquid Film Formation

During the final stages of solidification, a thin liquid film can form along grain boundaries. This liquid film can weaken the structure and promote grain boundary sliding, increasing the likelihood of hot tearing. Factors influencing this mechanism include:

- Alloy composition

- Solidification range

- Cooling rate

- Grain size and morphology

By understanding these mechanisms, foundries can develop targeted strategies to mitigate hot tearing in copper castings.

Effective Countermeasures for Hot Tearing Prevention

Optimizing Alloy Composition

One of the most effective ways to reduce hot tearing susceptibility in copper castings is by optimizing the alloy composition. Consider the following strategies:

- Adjust the copper-to-alloying element ratios

- Add grain refiners to promote a finer grain structure

- Incorporate elements that improve feeding characteristics

- Reduce impurities that can lower the solidification range

By carefully tailoring the alloy composition, foundries can significantly reduce the risk of hot tearing in their copper castings.

Improving Mold Design and Gating Systems

Proper mold design and gating systems play a crucial role in preventing hot tearing. Consider the following approaches:

- Optimize mold geometry to promote uniform cooling

- Implement strategic placement of risers and feeders

- Design gating systems that minimize turbulence and promote directional solidification

- Use chills or cooling channels to control thermal gradients

By improving mold design and gating systems, foundries can enhance the overall quality of their copper castings and reduce the incidence of hot tearing.

Controlling Pouring and Solidification Parameters

Careful control of pouring and solidification parameters is essential for minimizing hot tearing in copper castings. Consider the following strategies:

- Optimize pouring temperature to balance fluidity and solidification rate

- Control cooling rates to promote uniform solidification

- Implement proper mold preheating techniques

- Use computer simulations to predict and optimize solidification patterns

By fine-tuning these parameters, foundries can significantly reduce the risk of hot tearing and improve the overall quality of their copper castings.

Conclusion

Hot tearing in copper castings is a complex issue that requires a comprehensive understanding of its mechanisms and effective countermeasures. By optimizing alloy composition, improving mold design, and controlling solidification parameters, foundries can significantly reduce the occurrence of hot tearing and enhance the quality of their copper castings. Implementing these strategies not only improves product performance but also reduces scrap rates and production costs, ultimately leading to more efficient and profitable casting operations.

FAQs

1. What are the main causes of hot tearing in copper castings?

The main causes include alloy composition, solidification range, cooling rate, mold design, pouring temperature, and casting geometry.

2. How can I prevent hot tearing in my copper castings?

Prevent hot tearing by optimizing alloy composition, improving mold design and gating systems, and carefully controlling pouring and solidification parameters.

3. What impact does hot tearing have on casting quality?

Hot tearing can lead to reduced mechanical strength, decreased corrosion resistance, compromised dimensional accuracy, increased scrap rates, and higher production costs.

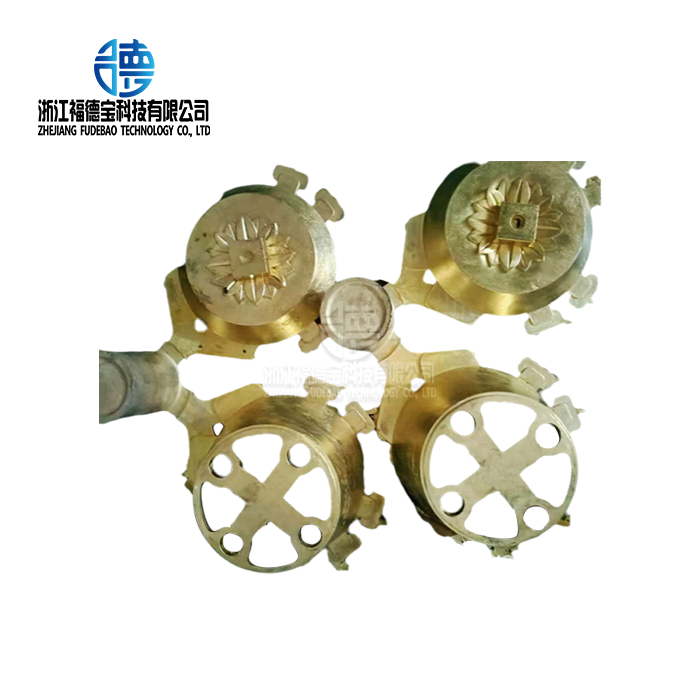

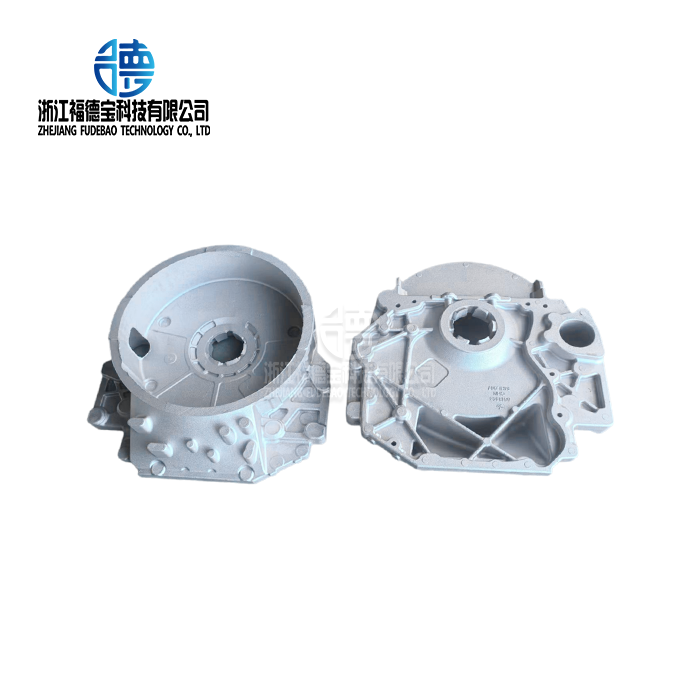

Expert Copper Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality copper castings and precision machining. Our expert team employs advanced techniques to prevent hot tearing and ensure superior product quality. As a leading copper casting manufacturer and supplier, we offer tailored solutions for various industries. Contact us at hank.shen@fdbcasting.com to learn how we can meet your copper casting needs with excellence and reliability.

References

1. Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

2. Eskin, D. G., Suyitno, & Katgerman, L. (2004). Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Progress in Materials Science, 49(5), 629-711.

3. Monroe, C., & Beckermann, C. (2005). Development of a hot tear indicator for steel castings. Materials Science and Engineering: A, 413, 30-36.

4. Rappaz, M., Drezet, J. M., & Gremaud, M. (1999). A new hot-tearing criterion. Metallurgical and Materials Transactions A, 30(2), 449-455.

5. Viano, D., StJohn, D., Grandfield, J., & Cáceres, C. (2005). Hot tearing in aluminium–copper alloys. Light Metals, 2005, 1069-1073.

6. Zhang, L., & Li, L. (2013). Determination of heat transfer coefficient at metal/die interface of high pressure die casting process of AM50 magnesium alloy. China Foundry, 10(1), 27-31.

_1756346668222.webp)

_1756349002499.webp)

_1756349071334.webp)

_1756350046757.webp)

_1756352400994.webp)