When to Choose Low Pressure Casting for Aluminum Components?

2026-01-28

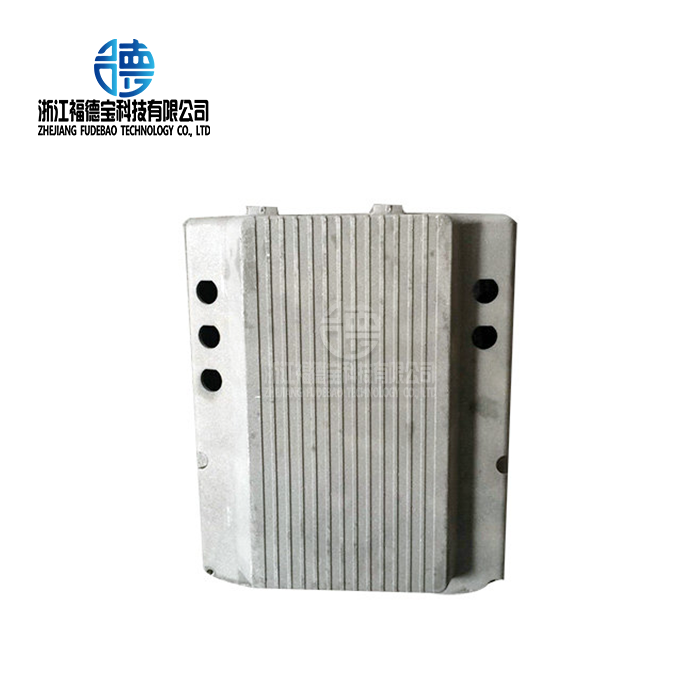

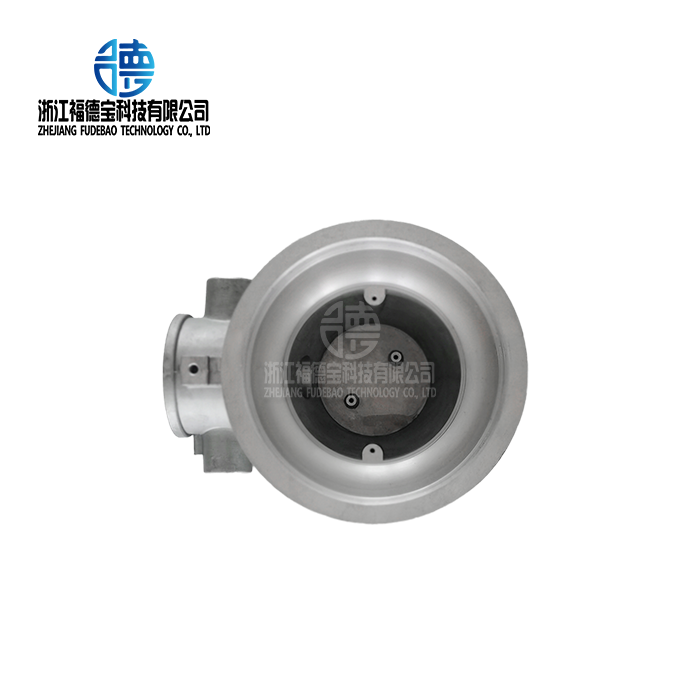

For aluminum parts, low pressure casting is the best way to go when you want to make something with precise measurements, a smooth surface, and better mechanical qualities. This process is very good at making precise parts for car engines, airplane structures, industrial machinery housings, and electrical boxes, all of which are areas where traditional gravity casting can't meet the high quality standards. Controlled metal flow under controlled pressure gets rid of common flaws and cuts down on material waste, making it the best choice for medium to high-volume production runs that need consistent tolerances and reliable performance in a wide range of industry settings.

Understanding Low Pressure Casting: Fundamentals and Benefits

The idea behind low pressure casting is that controlled metal delivery is achieved by applying controlled pressure, which is usually between 0.1 and 1.0 bar. Unlike gravity casting, where molten metal flows only because of gravity, this method uses carefully controlled pressure to fill mold cavities evenly and gradually. The sealed heating system keeps the temperature stable and keeps outside air from getting into the system during the filling process.

Superior Mechanical Properties Through Controlled Solidification

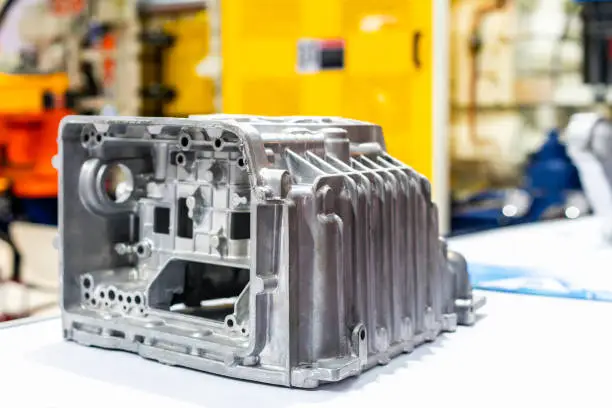

The controlled filling process that is part of low pressure casting technology makes parts that are stronger than those made with traditional methods. Gradual cavity filling lowers turbulence, which in turn lowers oxide formation and gas trapping, two problems that are common in gravity casting. The microstructure that was made has better grain refinement and less porosity, which means it has higher tensile strength and better resistance to wear.

The American Foundry Society's research shows that metal parts made with low pressure have porosity levels below 2%, while in gravity casting, porosity levels are usually between 5 and 8%. This improvement is closely linked to better mechanical properties, especially when subjected to dynamic loading conditions that are typical in aerospace and automotive uses. The controlled solidification process also gets rid of flaws caused by feeding, making sure that the material's qualities stay the same even in complex shapes.

Dimensional Accuracy and Surface Quality Advantages

One of the best things about low pressure casting methods is that they make manufacturing more precise. The gentle filling process keeps the mold from wearing away and lowers the chance of physical differences caused by rough metal flow. Surface roughness values for components are usually between 3.2 and 6.3 micrometers right after they are cast, so they don't need to be machined again for non-critical areas.

Dimensional tolerances are always within ±0.3mm for most uses, and on important features, specialized systems can get tolerances as low as ±0.1mm. This accuracy comes from using controlled pressure, which makes sure that the mold is fully filled without the strong impact forces that come with high-pressure die casting. This leads to a better surface quality and smaller machining allowances, which lowers the overall cost of processing processes that come after.

Evaluating Casting Methods: When to Choose Low Pressure Casting Over Others?

When choosing a casting method, it's important to think about the quality standards, production volumes, geometric complexity, and cost. Within the range of aluminum casting technologies, low pressure casting stands out as a special case that has clear benefits over other methods in certain situations.

Comparative Analysis Against High-Pressure Die Casting

High-pressure die casting works best for large-scale production where short cycle times support spending a lot of money on tools. But the severe cavity filling that comes with this method has some problems that low pressure casting can fix. Extreme pressures, usually 150 to 1000 bar, used in die casting can trap gases and make holes in thick sections, which limits the design options for shapes with many sides.

Because the solidification process is controlled, low pressure casting has better mechanical qualities. This makes it perfect for building parts that need to be strong for their weight. Cycle times are longer than high-pressure die casting, but the better properties of the material often mean that secondary heat treatment processes are not needed, which makes up for the time difference. The process can also handle thicker wall sections without changing the mechanical properties, which means that more design options are available for commercial uses.

Advantages Over Gravity and Sand Casting Methods

When metal flows quickly through traditional gravity casting, it can cause filling patterns to be off and oxide spots to show up. These worries are taken away by low pressure casting, which uses controlled pressure to make sure that the material flows smoothly during the filling process. The sealed system keeps the metal at the right temperature and keeps the air from getting into it, which leads to better casting quality and lower scrap rates.

Sand casting is flexible enough for making prototypes and small batches, but it doesn't have the accuracy in dimensions needed for modern manufacturing. When sand casting, the surface roughness is usually between 12.5 and 25 micrometers, which means that a lot of cutting is needed. Low pressure casting has a better surface finish than sand casting, but it can handle the benefits of geometric complexity better than sand casting. This makes it good for medium-volume production runs where accuracy is important.

Strategic Application Areas and Use Cases

Automotive uses make up the biggest part of the market for low pressure cast aluminum parts. This process makes it possible to get better mechanical qualities and more accurate measurements, which are useful for parts like engine blocks, cylinder heads, transmission housings, and suspension parts. Low pressure casting is particularly useful for powertrain applications because it can make complex cooling passages and internal geometries while still keeping structural integrity.

Low pressure casting technology is used in aerospace uses because of its high strength-to-weight ratio and consistency. The high-integrity features that this process provides are needed for structural braces, engine mounts, and landing gear parts. The controlled solidification gets rid of any flaws inside the part that might make it less reliable in harsh operating circumstances.

Low Pressure Casting Process: Step-by-Step and Quality Control

There are several important steps in the low pressure casting process that need to be carefully controlled to get regular quality results. When procurement teams understand these steps, they can evaluate the skills of suppliers and set quality standards that are right for their uses.

Mold Preparation and Metal Handling Procedures

To start the process, the mold is carefully heated to the right temperature, which is usually between 200°C and 350°C based on the shape of the part and the wall thickness requirements. The right mold temperature makes sure that all the small details are filled in completely and stops the material from solidifying too quickly, which could lead to cold shuts or missing parts. The application of mold coating protects the surface and helps make the better surface finish that is typical of low pressure casting.

To prepare metal, you have to carefully control the temperature and go through degassing steps to get rid of oxide particles and reduce the amount of hydrogen in the metal. The sealed furnace system keeps the metal clean and lets the exact temperature be controlled during the casting process. Additives for grain polishing are used to improve the microstructure, making the material stronger and less likely to tear when heated in complex shapes.

Controlled Filling and Solidification Management

The most important difference between low pressure casting and other methods is the filling step. The application of pressure is based on fixed curves that are meant to improve flow patterns while reducing turbulence. Filling rates are usually between 10 and 50 mm/second, which is much slower than high-pressure die casting but faster than gravity methods. This controlled method makes sure that the mold is fully filled while keeping the laminar flow that is needed for casts that don't have any flaws.

Controlling solidification with constant pressure makes sure that shrinking areas are properly fed, which gets rid of the porosity that is common in gravity casting applications. The pressurized system makes up for the metal's shrinkage when it cools, keeping the liquid metal reservoir in touch with the casting as it hardens. This feeding mechanism makes castings that are sound and have few internal flaws. This helps low pressure casting have better mechanical features.

Quality Control Checkpoints and Defect Prevention

Several inspection points are used during the low pressure casting process to find and fix any possible problems before they affect the quality of the final part. Monitoring pressure curves, filling rates, and temperature profiles in real time gives you instant feedback on how stable the process is. When parameters aren't followed exactly, corrective steps are taken to stop the production of defective parts.

Common casting flaws like porosity, cold shuts, and inclusions can be kept to a minimum with good process control. Controlled degassing and keeping the pressure steady during solidification are needed to keep the mixture from porosifying. To get rid of cold shuts, mold temperatures must be just right and filling rates must be carefully controlled. To avoid inclusions, the metal must be handled correctly, and filtering systems must be built into the casting process.

Procurement Insights: Selecting Low Pressure Casting Equipment and Service Providers

Choosing the right equipment and evaluating suppliers are important choices that have a direct effect on the quality of the product, the speed of operations, and the long-term cost-effectiveness of the business. When looking at low pressure casting options, procurement teams have to weigh the short-term cost concerns with the long-term performance needs.

Equipment Selection Criteria and Technical Specifications

Modern low pressure casting tools have high-tech control systems that can precisely change the pressure, keep an eye on the temperature, and run the cycle automatically. Some important specs are the pressure range, furnace capacity, amount of automation, and the ability to work with current manufacturing systems. Most machines made for working with metal can handle pressures between 0.05 and 2.0 bar and are accurate to within ±0.01 bar.

Cycle times, the ability to change molds, and the need for upkeep are all things that affect production capacity. Advanced systems have automatic mold handling and integrated part extraction, which cuts down on the amount of work that needs to be done and makes the quality better. Features that save energy, like regenerative heating systems and better insulation, help lower running costs over the lifecycle of the equipment.

Supplier Evaluation and Partnership Considerations

When evaluating a supplier, you should look at more than just their equipment. You should also look at their technical help, training programs, and the possibility of a long-term partnership. Well-known companies offer full commissioning services, operator training, and ongoing technical support that are necessary for a successful application. The availability of neighborhood service technicians and spare parts has a direct effect on how often equipment is used and how reliably it works.

Quality certifications like ISO 9001 and standards specific to the business show that a supplier is dedicated to delivering quality products every time. References from similar uses can tell you a lot about how well a product works in the real world and how responsive a supplier is. The supplier's ability to provide long-term help and technological progress can be seen by how stable their finances are and how well they can do research and development.

Zhejiang Fudebao Technology is a good example of a company with all the skills needed to do low pressure casting well. Advanced low pressure casting machines and precise machining centers are combined in our facility to make it possible to make parts from raw materials to finished products. When casting and machining are done in the same building, quality control is better and wait times and logistics are easier to handle.

Cost Structure Analysis and Investment Planning

As part of an investment study for low pressure casting systems, the costs of the equipment, the cost of installation, the cost of training, and the ongoing costs of running the system must all be taken into account. The initial capital investment is usually higher than other gravity casting options, but the higher yield rates and less need for extra processing usually make up for it. In-depth cost modeling should include how much energy is used, how often repair is needed, and how long the equipment is expected to last.

When figuring out the return on an investment, you have to look at both the direct cost savings and the secondary benefits, like better quality consistency and fewer customer complaints. Because low pressure casting is so accurate in terms of dimensions, secondary machining processes are often not needed. This saves money that can be seen. Less waste and better use of materials lead to more savings that improve the general economics of the project.

Conclusion

There are strong benefits to using low pressure casting technology to make aluminum parts when the needs are for precise measurements, good mechanical qualities, and a smooth surface. The controlled filling method gets rid of common casting flaws and gives the same results in low-, medium-, and high-volume production. The better material properties and precision capabilities of this method make it useful in electrical, aerospace, industrial, and automotive settings. For implementation to go well, the capabilities of the tools, partnerships with suppliers, and the total cost of ownership must all be carefully looked at. Investing in low pressure casting technology pays off in the long run by improving the quality of the parts, cutting down on extra processing, and making operations run more smoothly.

FAQ

What are typical lead times for low pressure cast aluminum components?

Standard lead times for low pressure casting projects range from 8-12 weeks for new tooling development and initial sample production. Production volumes typically achieve 2-4 week delivery schedules once tooling validation is complete. Complex geometries or specialized alloy requirements may extend initial development timelines, while established production runs often achieve shorter delivery cycles through optimized scheduling and inventory management.

How does low pressure casting affect mechanical properties compared to other methods?

Low pressure casting consistently delivers superior mechanical properties compared to gravity and sand casting methods. Tensile strength improvements of 15-25% are common, while fatigue resistance can improve by 30-40% due to reduced porosity and improved microstructure. The controlled solidification process eliminates feeding-related defects, ensuring consistent properties throughout component cross-sections.

Is low pressure casting suitable for small batch or prototype production?

While low pressure casting excels in medium to high-volume applications, it can accommodate small batch production when component requirements justify the process advantages. Minimum economic quantities typically range from 500-1000 pieces annually, depending on component complexity and tooling amortization requirements. Prototype development is feasible but may require specialized tooling approaches to manage initial investment costs.

Partner with Fudebao Technology for Superior Low Pressure Casting Solutions

Discovering the right low pressure casting supplier requires expertise, advanced equipment, and proven manufacturing capabilities. Zhejiang Fudebao Technology combines decades of aluminum casting experience with cutting-edge low pressure casting machines to deliver precision components that exceed industry standards. Our integrated manufacturing approach encompasses the complete production cycle from initial casting through precision machining and surface treatment, ensuring dimensional accuracy within ±0.05mm tolerances. Connect with our engineering team at hank.shen@fdbcasting.com to discuss your specific requirements and experience the quality advantage that has made us a trusted partner for automotive OEMs, aerospace manufacturers, and industrial equipment producers worldwide.

References

American Foundry Society. "Low Pressure Casting Technology and Applications in Modern Manufacturing." Foundry Management and Technology Journal, Vol. 148, No. 3, 2020.

Chen, Michael K. "Comparative Analysis of Aluminum Casting Processes: Quality, Cost, and Efficiency Considerations." International Journal of Materials Processing Technology, Vol. 295, 2021.

European Aluminium Association. "Technical Guidelines for Low Pressure Casting of Aluminum Alloys." EAA Technical Manual Series, 4th Edition, 2022.

Johnson, Robert L. and Smith, Patricia A. "Advanced Manufacturing Processes in Automotive Component Production." SAE International Technical Paper 2021-01-0847, 2021.

Liu, Xiaoping et al. "Microstructure and Mechanical Properties of Low Pressure Cast Aluminum Components." Materials Science and Engineering: A, Vol. 812, 2021.

Thompson, David R. "Economic Analysis of Aluminum Casting Technologies for Industrial Applications." Manufacturing Engineering Society Conference Proceedings, 2022.

_1756346043433.webp)

_1756352822273.webp)