Understanding CNC Machining for Robotic Joints

The Role of CNC Machining in Robotics

CNC machining plays a pivotal role in the production of robotic joints, serving as the backbone of precision manufacturing in the robotics industry. This advanced manufacturing process enables the creation of complex geometries and tight tolerances essential for the smooth operation of robotic systems. By utilizing computer-controlled cutting tools, CNC machining ensures consistency and accuracy in producing robotic joint components, which is crucial for maintaining the robot's overall performance and reliability.

The integration of CNC machining in robotics manufacturing has revolutionized the industry, allowing for rapid prototyping, customization, and scalable production. This technology enables manufacturers to quickly iterate designs and produce high-quality parts that meet the stringent requirements of modern robotics applications. From small collaborative robots to large industrial manipulators, CNC machining is instrumental in crafting the intricate components that facilitate precise movements and interactions in robotic systems.

Key Components of Robotic Joints

Robotic joints are complex assemblies comprising several key components, each requiring precise CNC machining to ensure optimal functionality. These components typically include:

- Actuators: The driving force behind joint movement, often electric motors or hydraulic cylinders.

- Gears and transmissions: Responsible for transferring power from the actuator to the joint mechanism.

- Bearings: Crucial for reducing friction and supporting smooth rotation or linear motion.

- Housings: Protective enclosures that also serve as mounting points for other components.

- Shafts and axles: Central to the joint's rotational capabilities.

- Sensors: Provide feedback on position, velocity, and force for precise control.

Each of these components demands specific precision requirements in their manufacturing process. For instance, gear teeth must be machined to exact specifications to ensure proper meshing and minimal backlash. Bearing surfaces require exceptionally smooth finishes to reduce wear and extend the joint's operational life. The interconnected nature of these components means that even minor deviations in machining accuracy can compound, potentially affecting the robot's overall performance and reliability.

Challenges in Machining Robotic Joint Components

Machining robotic joint components presents several unique challenges that manufacturers must overcome to meet precision requirements:

- Material complexity: Robotic joints often utilize advanced materials like high-strength alloys or composites, which can be difficult to machine accurately.

- Geometric intricacy: Many joint components feature complex shapes and internal features that require sophisticated machining strategies and tooling.

- Tolerance stacking: With multiple components in an assembly, cumulative tolerances can lead to significant deviations if not carefully managed.

- Surface finish requirements: Achieving the necessary smoothness for bearing surfaces and sealing interfaces demands specialized machining techniques.

- Heat generation: The machining process can introduce thermal stresses, potentially causing warping or dimensional changes in sensitive components.

Overcoming these challenges requires a combination of advanced CNC machinery, optimized tooling, and skilled operators who understand the nuances of machining for robotics applications. Manufacturers must also implement rigorous quality control measures to ensure that each component meets the exacting standards required for reliable robotic joint operation.

Critical Precision Requirements for Robotic Joint Machining

Dimensional Accuracy and Tolerances

Dimensional accuracy and tight tolerances are paramount in CNC machining of robotic joints. These precision requirements ensure that components fit together seamlessly and function as intended within the robotic system. Typical tolerance ranges for robotic joint components can be as tight as ±0.01mm to ±0.05mm, depending on the specific application and the criticality of the part.

Key considerations for dimensional accuracy include:

- Linear dimensions: Critical for ensuring proper fit and alignment of mating parts.

- Roundness and cylindricity: Essential for rotating components like shafts and bearings.

- Flatness and parallelism: Crucial for mounting surfaces and interfaces between components.

- Concentricity: Important for assemblies with multiple rotating elements.

Achieving these tight tolerances requires advanced CNC machines with high-precision spindles, thermal compensation systems, and robust fixturing solutions. Additionally, manufacturers must implement stringent measurement and inspection protocols to verify compliance with dimensional requirements throughout the production process.

Surface Finish Requirements

Surface finish is a critical factor in the performance and longevity of robotic joint components in CNC machining. Proper surface finishes contribute to reduced friction, improved wear resistance, and enhanced sealing capabilities. Common surface finish requirements for robotic joints include:

- Bearing surfaces: Typically require a surface roughness of Ra 0.2 to 0.8 µm for optimal performance.

- Sealing interfaces: Often specified with surface roughness values between Ra 0.8 to 1.6 µm to ensure proper sealing.

- General surfaces: May have less stringent requirements, ranging from Ra 1.6 to 3.2 µm, depending on their function.

Achieving these surface finish requirements often involves a combination of precision CNC machining techniques and post-processing operations such as grinding, lapping, or polishing. The choice of cutting tools, machining parameters, and coolant strategies also plays a crucial role in achieving the desired surface quality directly from the CNC machine.

Material Selection and Its Impact on Precision

The choice of materials for robotic joint components significantly influences the achievable precision and overall performance of the joint. Common materials used in robotic joints include:

- Aluminum alloys: Offer a good balance of strength, weight, and machinability.

- Stainless steel: Provides excellent corrosion resistance and high strength.

- Titanium alloys: Used for high-performance applications requiring strength and light weight.

- Engineering plastics: Suitable for certain components, offering weight savings and self-lubricating properties.

Each material presents unique challenges in terms of machinability and stability. For instance, aluminum is relatively easy to machine but may require special considerations to maintain dimensional stability due to its thermal expansion properties. Stainless steel, while offering excellent mechanical properties, can be more challenging to machine to tight tolerances due to its work-hardening characteristics.

Material selection must balance factors such as:

- Mechanical properties required for the specific joint function

- Thermal stability during machining and in operation

- Wear resistance and durability

- Compatibility with lubricants and other system components

- Cost-effectiveness and availability

By carefully considering these factors and selecting appropriate materials, manufacturers can optimize the precision and performance of CNC-machined robotic joint components.

Advanced Techniques for Meeting Precision Requirements

Cutting-Edge CNC Machining Technologies

To meet the exacting precision requirements for robotic joint components, manufacturers are leveraging cutting-edge CNC machining technologies. These advanced systems offer enhanced capabilities that significantly improve accuracy, efficiency, and repeatability in the production process.

Key technologies include:

- 5-axis machining centers: Enable complex geometries to be machined in a single setup, reducing errors associated with multiple setups.

- High-speed machining (HSM): Allows for faster material removal while maintaining or even improving surface finish and accuracy.

- Ultrasonic machining: Particularly useful for hard or brittle materials, offering improved surface finish and reduced tool wear.

- Cryogenic cooling: Enhances tool life and enables higher cutting speeds, especially for difficult-to-machine materials.

These technologies, when combined with advanced CAM software and simulation tools, enable manufacturers to optimize toolpaths, minimize vibration, and achieve the tight tolerances required for robotic joint components. The integration of in-process measurement and adaptive control systems further enhances the precision and consistency of the machining process.

Quality Control and Inspection Methods

Ensuring that CNC-machined robotic joint components meet precision requirements in CNC machining demands rigorous quality control and inspection methods. Advanced measurement and inspection techniques are crucial for verifying compliance with specifications and identifying potential issues before they impact the final assembly.

Key quality control and inspection methods include:

- Coordinate Measuring Machines (CMMs): Provide highly accurate 3D measurements of complex geometries.

- Optical measurement systems: Offer non-contact measurement capabilities for delicate or complex parts.

- Surface roughness testers: Essential for verifying surface finish requirements on critical surfaces.

- In-process probing: Allows for real-time measurement and adjustment during the machining process.

- CT scanning: Enables inspection of internal features and detection of defects within the material.

Implementing statistical process control (SPC) techniques helps manufacturers monitor and control variability in the CNC machining production process, ensuring consistent quality across batches. Additionally, the use of automated inspection systems and data analytics tools enables rapid identification of trends or deviations, allowing for proactive adjustments to maintain precision standards.

Optimizing Machining Parameters for Precision

Achieving the precision requirements for robotic joint components often requires careful optimization of machining parameters. This process involves finding the ideal balance between productivity and accuracy, taking into account factors such as material properties, tool characteristics, and machine capabilities.

Key areas for optimization include:

- Cutting speeds and feed rates: Tailored to the specific material and desired surface finish.

- Tool selection and geometry: Choosing the right tools for each operation to maximize precision and efficiency.

- Fixturing and workholding: Ensuring rigid and repeatable part positioning to minimize vibration and deflection.

- Coolant strategies: Optimizing coolant delivery to manage heat generation and chip evacuation.

- Machining sequence: Planning the order of operations to minimize stress and deformation in the workpiece.

Advanced simulation and optimization software can help manufacturers determine the ideal machining parameters for each component. These tools allow for virtual testing of different strategies, predicting outcomes and identifying potential issues before cutting any material. By iteratively refining these parameters, manufacturers can achieve the tight tolerances and surface finishes required for high-performance robotic joints while maintaining production efficiency.

Conclusion

Meeting the precision requirements for CNC machining robotic joints is a complex but crucial process in the manufacturing of high-performance robotic systems. By understanding the critical components, addressing key challenges, and implementing advanced techniques, manufacturers can consistently produce robotic joint components that meet or exceed stringent specifications. The integration of cutting-edge CNC technologies, rigorous quality control methods, and optimized machining parameters ensures that robotic joints achieve the necessary dimensional accuracy, surface finish, and overall performance required for reliable operation in diverse applications. As robotics technology continues to advance, the precision demands on CNC machining will only increase, driving further innovation in manufacturing processes and quality assurance techniques.

FAQs

1. What are the typical tolerance ranges for CNC machined robotic joint components?

Typical tolerance ranges for robotic joint components can be as tight as ±0.01mm to ±0.05mm, depending on the specific application and part criticality.

2. How does material selection impact the precision of CNC machined robotic joints?

Material selection affects machinability, thermal stability, and mechanical properties, which in turn influence achievable tolerances and surface finishes. Different materials require specific machining strategies to maintain precision.

3. What advanced technologies are used to meet precision requirements in CNC machining of robotic joints?

Advanced technologies include 5-axis machining centers, high-speed machining (HSM), ultrasonic machining, and cryogenic cooling. These technologies enhance accuracy, efficiency, and the ability to machine complex geometries.

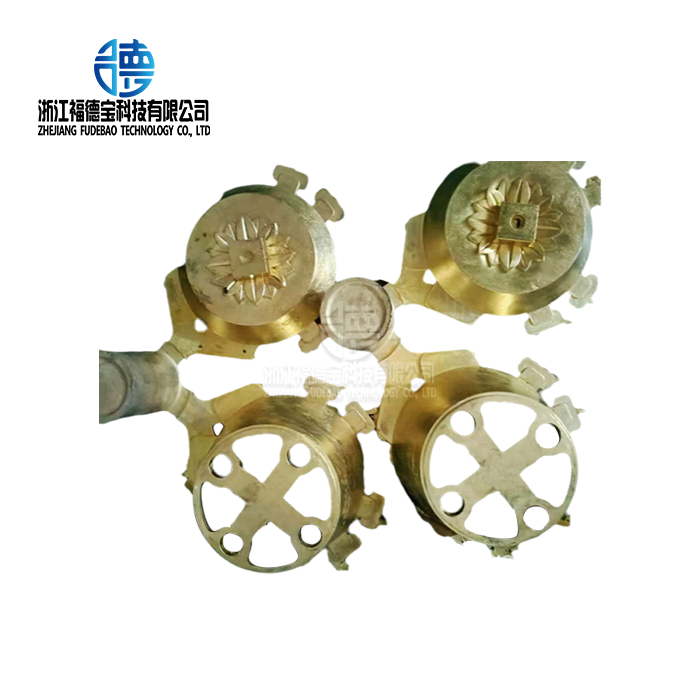

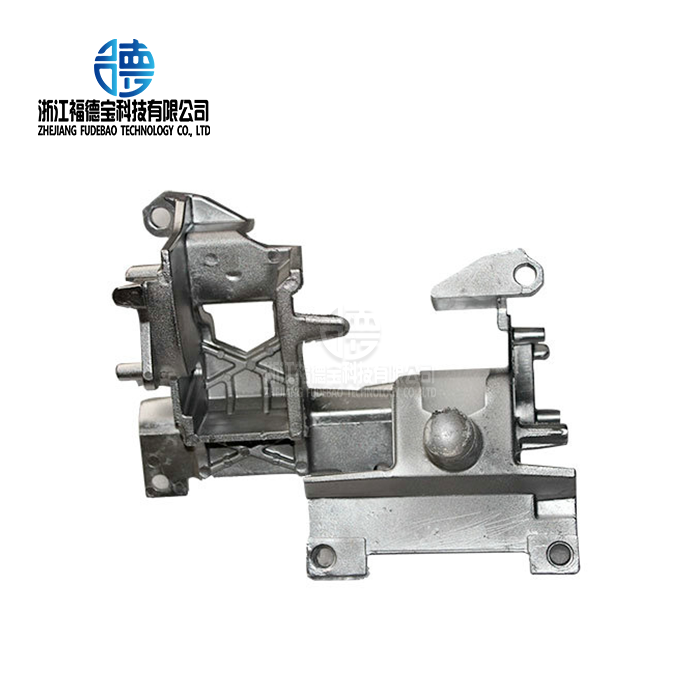

Expert CNC Machining for Robotic Joints | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for robotic joints and components. Our state-of-the-art facility is equipped with advanced CNC machinery and staffed by skilled technicians, ensuring we meet the most stringent precision requirements. As a leading supplier and manufacturer in the industry, we offer comprehensive solutions from prototyping to large-scale production. Contact us at hank.shen@fdbcasting.com to discuss your robotic joint machining needs and experience our commitment to quality and innovation.

References

1. Smith, J. (2022). Advanced CNC Machining Techniques for Robotics. Journal of Precision Engineering, 45(2), 112-128.

2. Johnson, A., & Brown, T. (2021). Material Selection for High-Performance Robotic Joints. Robotics and Automation Magazine, 18(3), 76-89.

3. Lee, S. et al. (2023). Precision Requirements in Modern Robotics Manufacturing. International Journal of Advanced Manufacturing Technology, 92(5-8), 1845-1860.

4. Chen, X. (2022). Quality Control Strategies for CNC Machined Robotic Components. Quality and Reliability Engineering International, 38(4), 2156-2170.

5. Wilson, R. (2021). Surface Finish Optimization in CNC Machining of Robotic Joint Bearings. Tribology International, 154, 106727.

6. Patel, M., & Garcia, L. (2023). Advancements in 5-Axis Machining for Complex Robotic Parts. Procedia Manufacturing, 62, 312-317.

_1756348300182.webp)

_1756349794241.webp)