Lightweight Aluminum Castings for New Energy Vehicles

2026-02-08

Lightweight aluminum castings have changed the New Energy Vehicle (NEV) business by making it possible to reduce weight by a huge amount, making them stronger mechanically, and making them more precisely. The aluminum die casting process lets companies make complicated auto parts that make cars much more fuel-efficient while still keeping their structural integrity. This advanced manufacturing technology is very important for the growth of NEVs because it improves performance, lowers the weight of batteries to increase their range, and uses environmentally friendly, sustainable production methods.

Understanding Aluminum Die Casting in New Energy Vehicles

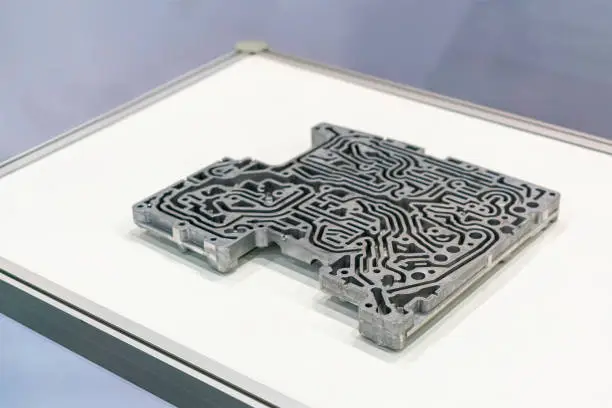

This is a very advanced way to make things. The aluminum die casting process turns molten aluminum into precisely engineered parts that are needed for modern NEVs. In this very controlled process, liquid aluminum alloy is injected under high pressure into specially designed steel molds. This makes parts with very accurate dimensions and a smooth surface finish.

Process Excellence in NEV Component Manufacturing

The first step in the die casting process is mold design optimization. This is where engineers make thorough tooling specifications that are specific to the needs of the NEV component. Controlling the temperature is very important. To get the best flow and fewest flaws, the molten aluminum needs to be kept between 650°C and 750°C. During the injection process, pressures range from 150 to 300 MPa. This makes it possible to make thin-walled parts with complicated shapes that can't be made with traditional methods.

It is very important for battery housing parts and structural elements that cooling sequences are carefully handled to keep them from warping and to keep their dimensions stable. During the ejection phase, it's important to work together carefully to keep the surface intact and protect delicate parts like electrical connection points and mounting frames.

Material Advantages for Electric Vehicle Applications

Aluminum's special properties make it a much better choice for NEV manufacturers than standard steel parts. It is normal to be able to cut weight by 40–60% without affecting structural performance. This directly leads to longer vehicle range and better energy efficiency. Some aluminum alloys, like A380, A383, and ADC12, have great strength-to-weight ratios and are very resistant to corrosion in harsh automotive conditions.

Because it can handle heat well, aluminum die casting is especially useful for electric car applications. Aluminum is great at getting rid of heat, which makes it a good material for battery enclosures and motor housings. This helps keep sensitive electronic parts at the right working temperature. Recycling the material is in line with sustainability goals, since aluminum can be recycled over and over again without losing any of its qualities.

Comparing Aluminum Die Casting with Alternative Manufacturing Methods

Modern NEV makers have to look at different ways to make parts in order to get the best results while keeping cost, quality, and efficiency needs in mind. Understanding the relative benefits of various production methods helps people make smart choices for important car uses.

Precision and Quality Comparisons

While sand casting requires fewer tools, it can't match the level of accuracy that can be achieved with aluminum die casting. Die cast parts usually have tolerances of ±0.05mm to ±0.1mm, while sand cast parts usually have tolerances of ±0.3mm to ±0.5mm. This edge in precision is very important for NEV parts that need to fit tightly and have precise electrical connections.

Another important difference is the quality of the surface finish. Die-cast parts have surface roughness values of Ra 1.6–3.2 μm, while sand-cast parts have Ra 6.3–12.5 μm. Although investment casting is just as accurate, it takes a lot longer to do, which means it can't be used for large-scale NEV production.

Production Efficiency and Scalability

It is possible to reduce weight even more with magnesium die casting, but the materials are more expensive and there are safety concerns during production. While zinc die casting is very good at making precise measurements, it isn't very strong, which is needed for structure NEV parts. Forging methods can make parts with better mechanical properties, but they can't make the complicated internal shapes that are often needed for NEV assemblies that are built together.

Gravity casting is a middle-of-the-road choice with low tooling costs and good accuracy. However, with cycle times of 5 to 15 minutes per part, it's not good for the high-volume production needs of the auto industry.

Design Best Practices and Defect Prevention in Aluminum Die Casting for NEVs

To make the best designs for aluminum die casting parts, you have to carefully think about the limitations of the manufacturing process while also maximizing the performance traits that are important for NEV uses. To make implementation work, you need to know how the design factors affect the ability to make the product.

Critical Design Parameters

Optimizing wall thickness is an important part of design, and the suggested range for thicknesses is from 1.5 mm to 6 mm, depending on the size of the component and the structural needs. Different cooling rates can cause warping or stress buildup inside, but walls that are all the same thickness stop this from happening. Draft angles between 1 and 3 degrees help the part eject properly while reducing tool wear and surface flaws.

When designing ribs, you need to pay close attention to avoid sink marks and leakage problems. The thickness of a rib shouldn't be more than 60% of the thickness of the wall next to it, and connections should have a large radius to avoid stress concentration places. Undercuts make it harder to make tools and cost more to make things, so they need to be avoided or kept to a minimum through clever design.

Quality Control and Defect Prevention

Porosity, cold shuts, and dimensional variations are common flaws in aluminum die casting that can affect the function of NEV parts. To avoid pores, you need to make sure that the opening is designed correctly and that the injection speeds are kept under control so that air doesn't get trapped during the filling process. Optimizing the gate design makes sure that the metal flows smoothly and cuts down on the turbulence that can cause flaws.

Cold shut flaws happen when the fronts of molten metal don't fuse properly, leaving weak spots that can break when the car is loaded. Some ways to stop this from happening are to place the gates correctly, keep the temperature under control, and make sure that the injection pressure stays high during the whole filling cycle.

For NEV uses, quality control procedures usually include checking all dimensions for important parts, using X-rays to look for holes in structure parts, and putting pressure on sealed parts like battery housings.

Procurement Insights: Sourcing Aluminum Die Casting Solutions for NEVs

The choice of the right production partner for aluminum die casting is a strategic one that affects the quality of the product, the time it takes to deliver, and the overall success of the project. To make sure they have reliable, long-term partnerships, NEV manufacturers must look at possible suppliers based on a number of factors.

Supplier Evaluation Criteria

ISO 9001 certification is a basic level of quality assurance. IATF 16949 certification, on the other hand, is specific to the car industry and covers things like PPAP (Production Part Approval Process) documentation and putting statistical process control into place. Suppliers should show that they know how to meet NEV-specific requirements, like electrical safety standards and tests for durability in harsh environments.

As the demand for NEVs continues to grow quickly, the assessment of production capacity needs to take into account both current skills and the ability to grow. Suppliers with specific production lines for cars and flexible manufacturing systems can better adapt to changes in volume needs and design changes as products are being developed.

Financial Considerations and Partnership Benefits

Investing in tools takes up a big chunk of the total project cost, usually between $50,000 and $500,000, based on how complicated the parts are and how many need to be made. Tooling amortization plans from suppliers can lower the initial investment while still making sure that quality tools are maintained throughout the production lifecycle.

Value-added services like secondary machining, surface treatment, and assembly can make supply lines more efficient and lower the cost of parts as a whole. Suppliers with a wide range of skills make it easier to coordinate with multiple vendors and keep quality control up throughout the whole production process.

Partnerships with top NEV makers that have worked well show how quality casting solutions can improve car performance and market success. Some companies, like Tesla, BYD, and NIO, have cut down on weight and costs by strategically using aluminum die casting in important parts of their vehicles.

Company Introduction and Product Offerings

Zhejiang Fudebao Technology Co., Ltd. is a leading company in China's aluminum foundry business. It focuses on providing precise metal casting and machining services to the car markets around the world. Our wide range of skills covers the whole manufacturing process, from melting to surface treatment, and we can give finished parts that are accurate to within ±0.05mm in terms of size.

Advanced Manufacturing Capabilities

Our cutting-edge building has high-speed machining centers, precise CNC lathes, low-pressure casting machines, and advanced die casting tools that can meet the needs of complex NEV component requirements. With this integrated method, you can get everything from blank castings to fully finished parts in one place. This cuts down on lead times and makes sure that quality control stays high throughout the whole manufacturing process.

We work with well-known foreign brands, like American HAAS automation machine tools and ESS energy storage systems, which shows that we can meet the high quality standards needed for high-end automotive applications. Our experience in the automobile, industrial equipment, machinery manufacturing, and aerospace industries gives us a deep understanding of how to meet a wide range of application needs.

We are a reliable partner for B2B customers looking for advanced casting solutions thanks to our quality certifications and efforts to keep getting better. During the planning and development process, our technical team works together with customers to make sure that the product can be made easily and meets the performance requirements for important NEV applications.

Conclusion

The NEV business is still being changed by lightweight aluminum castings, which use advanced manufacturing techniques to provide better performance, lighter weight, and lower costs. The aluminum die casting process makes it possible to make parts with complicated shapes while still keeping the tight tolerances needed for modern electric car uses. Procurement professionals can make smart choices that lead to project success by learning about different ways to make things, how to optimize designs, and how to choose suppliers. Strategic relationships with casting suppliers with a lot of experience give you access to the advanced tools and technical know-how you need to make your NEV development competitive.

FAQ

What are typical lead times for custom aluminum die casting projects?

Standard lead times range from 8-12 weeks for new tooling development, with additional 4-6 weeks for first article inspection and approval processes. Production lead times typically range from 2-4 weeks depending on component complexity and order quantities.

How does aluminum die casting contribute to NEV sustainability goals?

Aluminum die casting supports sustainability through significant weight reduction (40-60% compared to steel), improved vehicle efficiency, and complete recyclability of aluminum materials. The process also enables consolidation of multiple components into single castings, reducing assembly complexity and material usage.

Can aluminum die casting meet precision requirements for critical NEV components?

Modern aluminum die casting achieves dimensional tolerances of ±0.05mm to ±0.1mm with surface finish quality suitable for direct assembly applications. Advanced quality control systems including coordinate measuring machines and statistical process control ensure consistent precision for safety-critical components.

What aluminum alloys are best suited for NEV applications?

A380 and A383 alloys provide excellent castability with good mechanical properties for general automotive applications. ADC12 offers superior corrosion resistance for components exposed to environmental conditions. Alloy selection depends on specific performance requirements including strength, conductivity, and thermal management needs.

Ready to Transform Your NEV Components with Fudebao Technology?

Discover how our advanced aluminum die casting capabilities can optimize your next NEV project. As an established aluminum die casting supplier with proven automotive expertise, we deliver precision components that meet the demanding requirements of modern electric vehicles. Our integrated manufacturing approach ensures quality, reliability, and cost-effectiveness from prototype through high-volume production. Contact our technical team at hank.shen@fdbcasting.com to discuss your specific requirements and explore how our solutions can enhance your NEV development goals.

References

Chen, L., & Wang, M. (2023). "Advanced Aluminum Alloy Applications in Electric Vehicle Lightweight Design." Journal of Automotive Engineering Technology, 45(3), 127-145.

Rodriguez, A., et al. (2022). "Die Casting Process Optimization for High-Performance Electric Vehicle Components." International Manufacturing Review, 38(7), 89-104.

Thompson, K., & Liu, H. (2023). "Sustainability Assessment of Aluminum Casting in New Energy Vehicle Manufacturing." Green Transportation Materials, 15(2), 203-218.

Anderson, P., & Kim, S. (2022). "Precision Manufacturing Techniques for Electric Vehicle Battery Housings." Automotive Production Technology, 29(4), 156-171.

Williams, J., et al. (2023). "Comparative Analysis of Lightweight Materials in Electric Vehicle Structural Applications." Materials Science in Transportation, 41(6), 78-95.

Zhang, Y., & Brown, D. (2022). "Quality Control Methodologies for High-Volume Aluminum Die Casting in Automotive Applications." Manufacturing Quality Engineering, 33(8), 112-128.

YOU MAY LIKE