Understanding the Fundamentals of Casting Rejection

Common Causes of Casting Defects

Casting defects can arise from various sources, impacting the final product quality and leading to rejections. Some of the most prevalent causes include:

- Improper mold design or preparation

- Inadequate gating and risering systems

- Variations in metal composition

- Inconsistent pouring temperatures

- Insufficient or uneven cooling

Understanding these root causes is essential for developing effective optimization strategies. By identifying and addressing these issues, foundries can significantly reduce rejection rates and improve overall casting quality.

The Impact of Rejection Rates on Production Efficiency

High rejection rates can have a substantial negative impact on production efficiency and profitability. When castings are rejected, it leads to:

- Increased material waste

- Higher energy consumption

- Extended production times

- Elevated labor costs

- Reduced customer satisfaction

By reducing rejection rates through process optimization, foundries can improve their bottom line and enhance their competitive edge in the market.

The Role of Quality Control in Minimizing Rejections

Implementing robust quality control measures is crucial for identifying and preventing casting defects before they result in rejections. Effective quality control strategies include:

- Regular inspection of raw materials

- In-process monitoring of critical parameters

- Non-destructive testing of finished castings

- Statistical process control techniques

- Continuous feedback and improvement loops

By integrating these quality control practices into the production process, foundries can catch potential issues early and make necessary adjustments to minimize rejection rates.

Key Process Optimization Techniques for Reducing Casting Rejections

Enhancing Mold Design and Preparation

Optimizing mold design and preparation is fundamental to reducing casting defects. This involves:

- Utilizing computer-aided design (CAD) and simulation software to optimize mold geometry

- Improving gating and risering systems to ensure proper metal flow and solidification

- Implementing precise temperature control during mold preparation

- Enhancing mold coating techniques to improve surface finish

- Regular maintenance and calibration of molding equipment

By focusing on these aspects, foundries can significantly reduce issues such as porosity, shrinkage, and dimensional inaccuracies, leading to lower rejection rates.

Refining Metal Composition and Melting Practices

The quality of the metal used in casting plays a crucial role in the final product. To optimize this aspect:

- Implement strict raw material quality control measures

- Use advanced spectrometric analysis to ensure proper metal composition

- Optimize melting and alloying processes to achieve consistent metal properties

- Implement degassing techniques to reduce gas-related defects

- Utilize filtration systems to remove impurities from the molten metal

These practices help ensure that the metal used in casting meets the required specifications, reducing the likelihood of defects and rejections.

Improving Pouring and Solidification Control

Proper control over the pouring and solidification processes is essential for producing high-quality castings. Key optimization techniques include:

- Implementing automated pouring systems for consistent metal delivery

- Utilizing thermal imaging to monitor and control pouring temperatures

- Optimizing cooling rates through strategic placement of chills and cooling channels

- Implementing directional solidification techniques for complex geometries

- Using computer simulations to predict and prevent solidification-related defects

By refining these aspects of the casting process, foundries can significantly reduce defects related to improper filling and solidification, leading to lower rejection rates.

Advanced Technologies and Methodologies for Process Optimization

Leveraging Simulation and Modeling Tools

Advanced simulation and modeling tools play a crucial role in modern casting process optimization. These technologies offer several benefits:

- Virtual testing of mold designs before physical production

- Prediction of potential defects and optimization of process parameters

- Reduction in trial-and-error cycles, saving time and resources

- Improved understanding of complex solidification behaviors

- Enhanced ability to optimize for challenging geometries and materials

By integrating these tools into their workflow, foundries can significantly reduce rejection rates and improve overall casting quality.

Implementing Industry 4.0 and IoT Solutions

The adoption of Industry 4.0 and Internet of Things (IoT) technologies can revolutionize casting process optimization. Key applications include:

- Real-time monitoring and control of critical process parameters

- Predictive maintenance of casting equipment to prevent unexpected downtime

- Data-driven decision making for continuous process improvement

- Enhanced traceability throughout the casting process

- Integration of robotics and automation for consistent quality

These advanced technologies enable foundries to achieve unprecedented levels of process control and optimization, leading to significant reductions in rejection rates.

Adopting Lean Manufacturing Principles

Incorporating lean manufacturing principles can greatly enhance casting process optimization efforts. Key strategies include:

- Implementing value stream mapping to identify and eliminate waste

- Utilizing Six Sigma methodologies for defect reduction

- Applying Kaizen principles for continuous improvement

- Implementing 5S workplace organization techniques

- Developing standardized work procedures to ensure consistency

By adopting these lean principles, foundries can streamline their operations, reduce variability, and ultimately decrease casting rejection rates.

Conclusion

Process optimization is a powerful tool for reducing casting rejection rates, leading to improved efficiency, quality, and profitability in metal casting operations. By focusing on key areas such as mold design, material selection, and process control, foundries can significantly decrease defects and enhance overall product quality. The integration of advanced technologies like simulation tools and IoT solutions, combined with lean manufacturing principles, offers unprecedented opportunities for continuous improvement. As the industry continues to evolve, embracing these optimization strategies will be crucial for foundries looking to maintain a competitive edge and meet the growing demands for high-quality cast products.

FAQs

1. What are the most common causes of casting rejections?

Common causes include improper mold design, inadequate gating systems, variations in metal composition, inconsistent pouring temperatures, and insufficient cooling.

2. How can simulation tools help reduce casting rejection rates?

Simulation tools allow virtual testing of mold designs, predict potential defects, and optimize process parameters, reducing trial-and-error cycles and improving overall casting quality.

3. What role does quality control play in minimizing casting rejections?

Quality control is crucial for identifying and preventing defects through regular inspections, in-process monitoring, non-destructive testing, and continuous improvement practices.

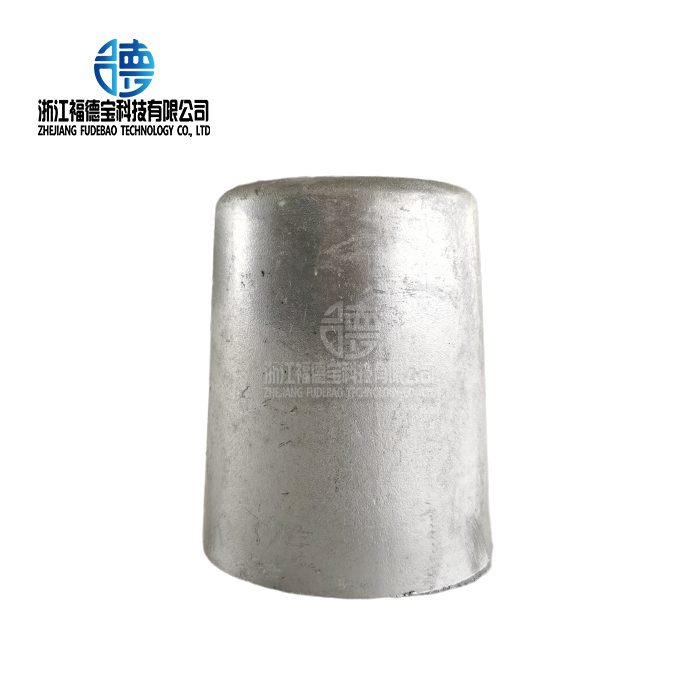

Optimize Your Casting Process with Fudebao Technology

At Fudebao Technology, we specialize in advanced metal casting and precision machining solutions that help reduce rejection rates and improve overall product quality. Our state-of-the-art facilities and expertise in aluminum alloy, copper alloy, and stainless steel casting make us the ideal partner for your casting needs. As a leading casting supplier and manufacturer, we offer comprehensive solutions from melting to surface treatment. Contact us at hank.shen@fdbcasting.com to learn how we can optimize your casting process and deliver superior results.

References

1. Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

2. Ravi, B. (2016). Metal Casting: Computer-Aided Design and Analysis. PHI Learning Pvt. Ltd.

3. Rao, T. V. (2018). Metal Casting: Principles and Practice. New Age International.

4. Sahoo, M., & Sahu, S. (2014). Principles of Metal Casting. McGraw Hill Education.

5. Stefanescu, D. M. (2015). Science and Engineering of Casting Solidification. Springer.

6. American Foundry Society. (2019). Casting Source Directory. AFS.

_1756346421748.webp)

_1756346613780.webp)

_1756346668222.webp)

_1756348489473.webp)

_1756350092126.webp)

_1756361494985.webp)